Reinforcing agent and preparation method thereof, and application of reinforcing agent

A technology of strengthening agent and dispersing agent, which is applied in the field of papermaking industry, can solve the problems affecting the strengthening effect of strengthening agent, the troubles of actual production in factories, and the limitation of paper machine speed, etc., and achieve the effect of improving application effect, high molecular weight and increasing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

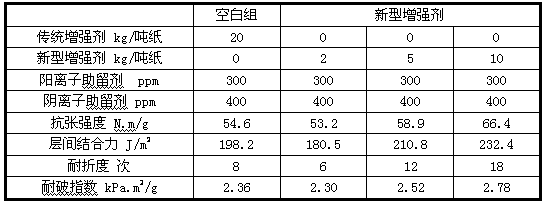

Examples

Embodiment 1

[0027] Dry strength agent: traditional anionic dry strength agent (A-PAM), with a solid content of more than 15% and a viscosity ≥ 5000cps.

[0028] Drugs: microcapsule wall material (gelatin, gum arabic), emulsifier (OP-10), citric acid for pH adjustment, dispersant: polyethylene-acrylic acid copolymer).

[0029] Anionic enhancer (A-PAM) for traditional papermaking was prepared:

[0030] Prepare microcapsule wall material solutions (gelatin and gum arabic solutions) respectively, with a concentration of 2%. Add gum arabic solution to the prepared anion enhancer A-PAM, the amount of gum arabic added is controlled at 80% (to the core material), and the emulsification of the solution is realized by high-speed stirring, and the rotation speed is generally controlled at 150 rpm. Add gelatin solution to the final solution, the amount of gelatin added is controlled within the range of 1:1 to the gum arabic, the emulsifier OP-10 is added, the dosage is controlled at 2%, and the pH o...

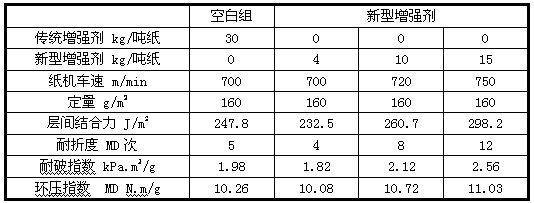

Embodiment 2

[0035] Dry strength agent: traditional cationic dry strength agent (C-PAM), with a solid content of more than 20%, viscosity ≥ 4000cps

[0036] Drugs: microcapsule wall material (PEG polyethylene glycol), emulsifier (polyoxyethylene ether), dispersant selection: polyacrylamide).

[0037] Cationic Strengthening Agent (C-PAM) for Conventional Papermaking

[0038] Prepare the microcapsule wall material solution (PEG) with a concentration of 4%. Add PEG solution to the prepared cationic enhancer C-PAM, the amount of PEG added is controlled at 50% (for the core material), and an emulsifier (polyoxyethylene ether) is added during high-speed agitation to realize emulsification of the solution, and the rotation speed is average Control at 250 rpm, add petroleum ether (the dosage is generally controlled at 1%~50%, preferably 10%~20%) into the emulsified solution to form microcapsule particles in the solution. After filtration, dehydration and drying, microcapsules are obtained. Then...

Embodiment 3

[0043] Dry strength agent: traditional cationic dry strength agent (C-PAM), with a solid content of more than 20%, viscosity ≥ 4000cps, traditional anionic dry strength agent (A-PAM), with a solid content of more than 15%, viscosity ≥ 5000cps

[0044] Drugs: microcapsule wall material (gelatin), emulsifier (TX-100 octylphenyl polyoxyethylene ether), flocculant: anionic and cationic polyacrylamide, dispersant: polyacrylamide). pH regulator, choose oxalic acid

[0045]Prepare microcapsule wall material solution (gelatin) with a concentration of 3%. Add gelatin solution to the prepared cationic enhancer C-PAM, the amount of gelatin added is controlled at 100% (for the core material), and emulsifier (TX-100) is added when stirring at high speed, the amount of emulsifier: 20%, to achieve a solution For emulsification, the rotation speed is generally controlled at 200 rpm, and oxalic acid is added to the emulsified solution, and the pH is controlled at about 5.0, so that the gelati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com