High graphitization three-dimensional carbon nanotube graphene composite material and preparation method and application thereof

A carbon nanotube, composite material technology, applied in the direction of electrode carrier/current collector, electrical components, battery electrodes, etc., can solve the problems of complex process, cumbersome shuttle effect, poor effect, etc., achieve simple synthesis method, protect integrity , the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

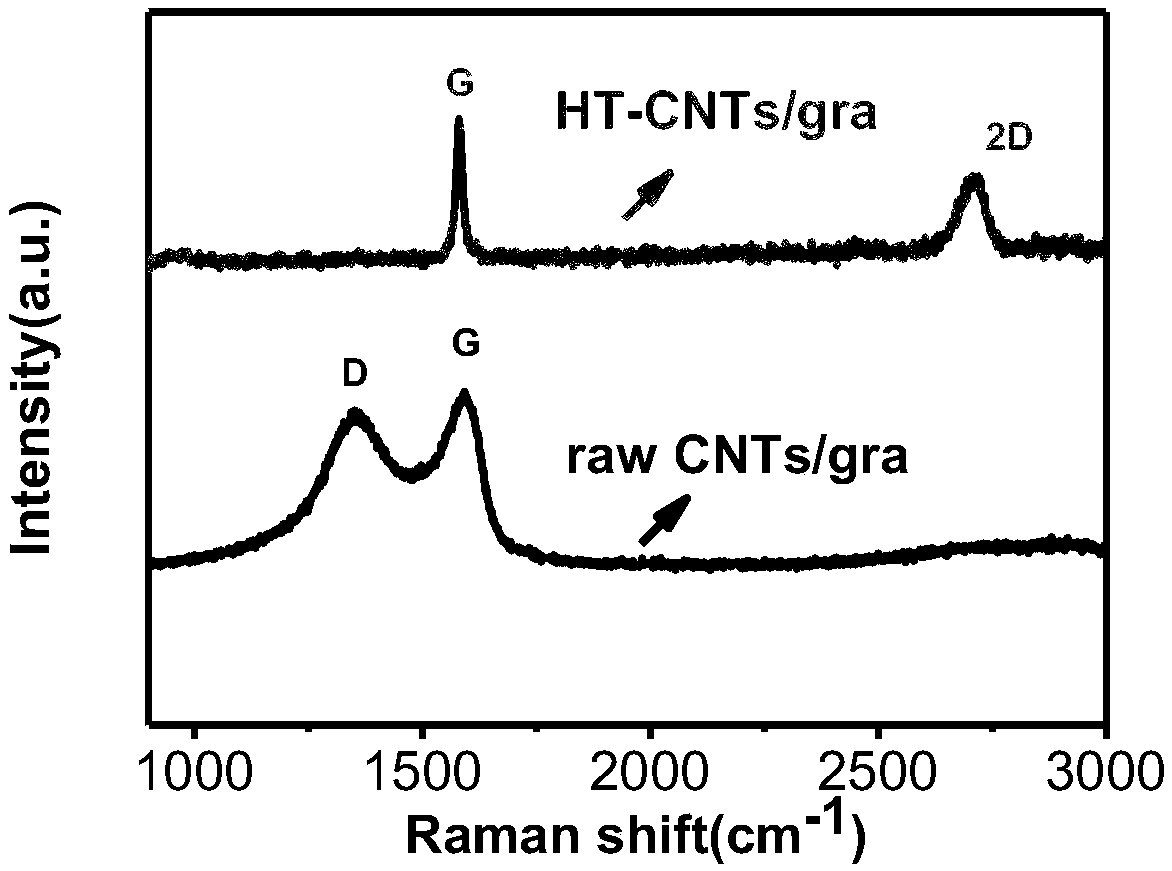

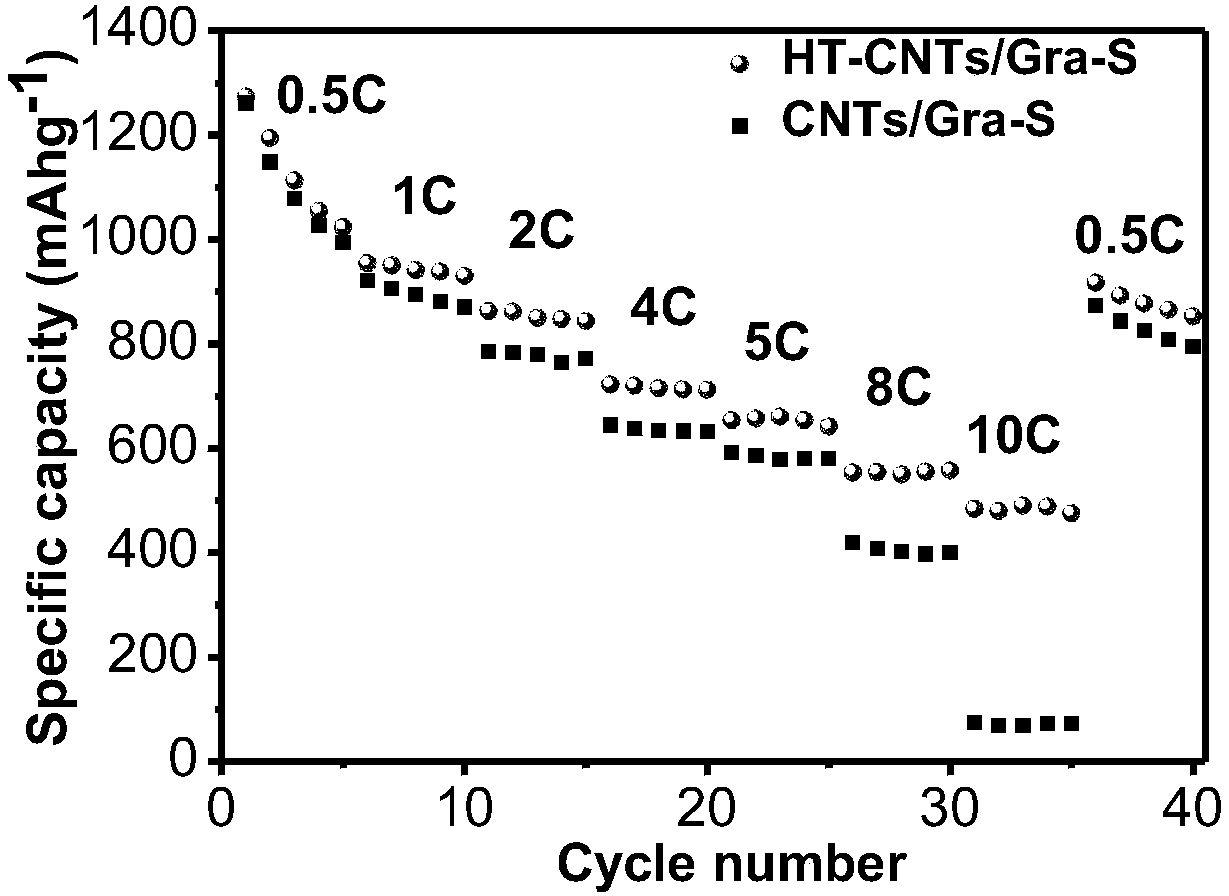

[0031] A. Preparation of highly graphitized three-dimensional carbon nanotube graphene composites:

[0032] (1) Weigh 1000 mg of multi-walled carbon nanotubes and 500 mg of multi-layer graphene, mix and dissolve them in 300 ml of ethanol, stir vigorously and supercharge for 2 hours, then place them in an oven at 75° C. to dry to obtain a carbon nanotube graphene composite;

[0033] (2) Place the carbon nanotube graphene composite obtained in step (1) in a high-temperature graphitization furnace body, and under the protection of high-purity argon, use the temperature programming method to first raise the temperature to 1200°C at 400°C / 0.5h °C, then the temperature was raised to 2850 °C at 300 °C / 0.5 h, and continued at 2850 °C for 2 h to obtain the highly graphitized three-dimensional carbon nanotube graphene composite material.

[0034] B. Preparation of lithium-sulfur secondary battery cathode sheet:

[0035] Take 300mg of highly graphitized three-dimensional carbon nanotube...

Embodiment 2

[0041] A. Preparation of highly graphitized three-dimensional carbon nanotube graphene composites:

[0042] (1) Weigh 500 mg of arrayed carbon nanotubes and 500 mg of multilayer graphene, mix and dissolve them in 200 ml of ethanol, stir vigorously and overgrow for 2 hours, and then place them in an oven at 75°C to dry to obtain carbon nanotube graphene composites.

[0043] (2) Place the carbon nanotube graphene composite obtained in step (1) in a high-temperature graphitization furnace body, and under the protection of high-purity argon, use the temperature programming method to first raise the temperature to 1200°C at 400°C / 0.5h °C, then the temperature was raised to 2850 °C at 300 °C / 0.5 h, and continued at 2850 °C for 2 h to obtain the highly graphitized three-dimensional carbon nanotube graphene composite material.

[0044] B. Preparation of lithium-sulfur secondary battery cathode sheet:

[0045] Take 300mg of highly graphitized three-dimensional carbon nanotube graphene c...

Embodiment 3

[0050] A. Preparation of highly graphitized three-dimensional carbon nanotube graphene composites:

[0051] (1) Weigh 1000 mg of arrayed carbon nanotubes and 500 mg of single-layer graphene, mix and dissolve them in 300 ml of ethanol, stir vigorously and overgrow for 3 hours, and then place them in an oven at 75°C to dry to obtain carbon nanotube-graphene composites.

[0052] (2) Place the carbon nanotube graphene composite obtained in step (1) in a high-temperature graphitization furnace body, and under the protection of high-purity argon, use the temperature programming method to first raise the temperature to 1200°C at 400°C / 0.5h °C, then the temperature was raised to 2850 °C at 300 °C / 0.5 h, and continued at 2850 °C for 3 h to obtain the highly graphitized three-dimensional carbon nanotube graphene composite material.

[0053] B. Preparation of lithium-sulfur secondary battery cathode sheet:

[0054] Take 300mg of highly graphitized three-dimensional carbon nanotube graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com