Three-dimensional porous flower-like structure cobalt/carbon nano-composite electromagnetic wave absorbing material and preparation method thereof

A carbon nanocomposite, flower-like structure technology, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems that are difficult to meet the requirements of high-performance electromagnetic wave absorbing materials, large-scale industrial production, and complex preparation processes, and achieve excellent Electromagnetic wave absorption performance, excellent electromagnetic wave absorption performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a cobalt / carbon nanocomposite electromagnetic wave absorbing material with a three-dimensional porous flower-like structure, comprising the following steps:

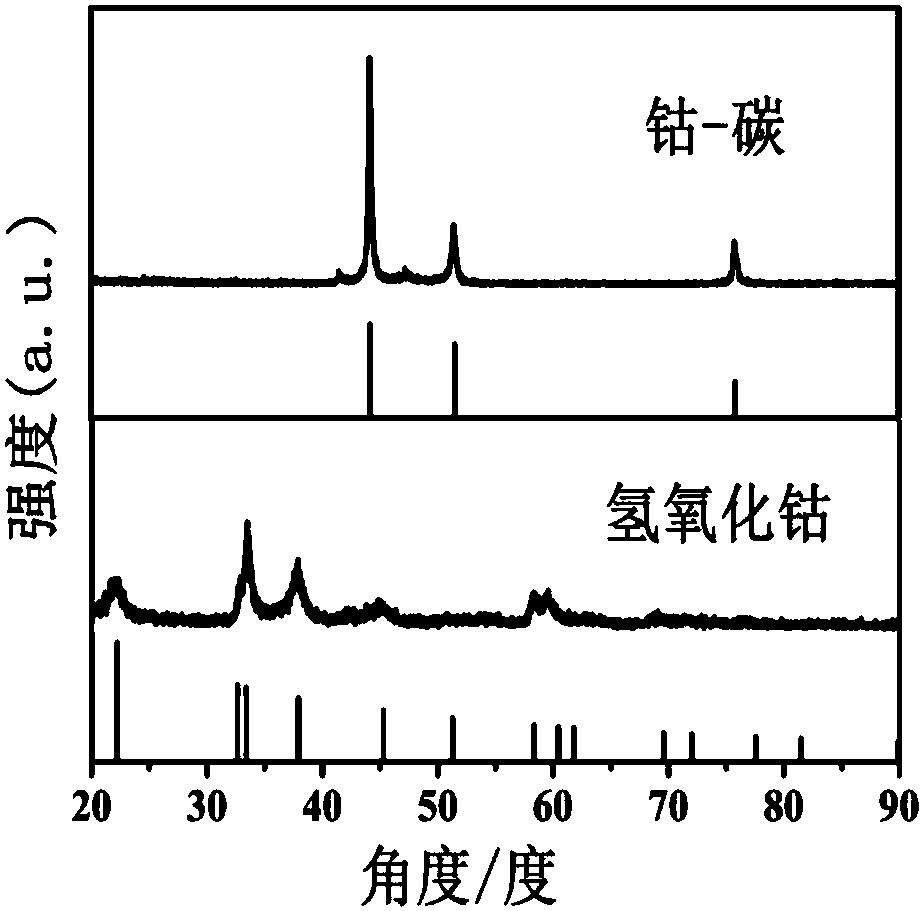

[0055] 1) Co(CH 3 COO) 2 4H 2 O is used as a precursor for synthesizing cobalt, polyvinylpyrrolidone is used as a surfactant, and is added to 100mL of methanol solvent at a mass ratio of 2:1. In a closed reaction kettle, react at 200°C for 3h. After the reaction is completed, the product is washed and dried. , to obtain cobalt hydroxide; calcining the obtained cobalt hydroxide at 350° C. for 3 hours to obtain tricobalt tetroxide powder;

[0056] 2) Mix 1.5g of cobalt tetroxide powder with 0.5g of pyrrole in step 1), and then react in a closed reaction kettle at 550°C for 5 hours to obtain a three-dimensional porous flower-like cobalt / carbon nanocomposite electromagnetic wave absorbing material.

[0057] The TG test was carried out on the electromagnetic wave absorbing material prepared in...

Embodiment 2

[0065] A method for preparing a cobalt / carbon nanocomposite electromagnetic wave absorbing material with a three-dimensional porous flower-like structure, comprising the following steps:

[0066] 1) CoCl 2 ·6H 2 O is used as a precursor for synthesizing cobalt, polyvinylpyrrolidone is used as a surfactant, and is added to 100mL methanol solvent at a mass ratio of 1:0.5. In a closed reaction kettle, react at 100°C for 30h. After the reaction is completed, the product is washed and dried. , to obtain cobalt hydroxide; calcining the obtained cobalt hydroxide at 300° C. for 5 hours to obtain tricobalt tetroxide powder;

[0067] 2) Mix 5g of cobalt tetroxide powder with 2g of pyrrole in step 1), and then react in a closed reaction kettle at 500°C for 30 hours to obtain a three-dimensional porous flower-like cobalt / carbon nanocomposite electromagnetic wave absorbing material.

[0068] The TG test was carried out on the electromagnetic wave absorbing material prepared in this embod...

Embodiment 3

[0072] A method for preparing a cobalt / carbon nanocomposite electromagnetic wave absorbing material with a three-dimensional porous flower-like structure, comprising the following steps:

[0073] 1) CoSO 4 ·6H 2 O is used as a precursor for synthesizing cobalt, polyvinylpyrrolidone is used as a surfactant, and is added to 100mL methanol solvent at a mass ratio of 1:4. In a closed reaction kettle, react at 400°C for 2 hours. After the reaction is completed, the product is washed and dried. , to obtain cobalt hydroxide; calcining the prepared cobalt hydroxide at 500°C for 1 hour to obtain tricobalt tetroxide powder;

[0074] 2) Mix 4g of cobalt tetroxide powder with 2g of pyrrole in step 1), and then react in a closed reaction kettle at 600°C for 2 hours to obtain a three-dimensional porous flower-like cobalt / carbon nanocomposite electromagnetic wave absorbing material.

[0075] A TG test was performed on the electromagnetic wave absorbing material prepared in this embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com