Sulfur, arsenic, phosphorus adsorbent and preparation method thereof

A technology of phosphorus adsorbent and parts by weight, which is applied in the field of arsenic, phosphorus adsorbent and its preparation, and sulfur, which can solve the problems of low adsorption capacity and high bulk density of adsorbent, so as to improve adsorption capacity, increase adsorption capacity, and improve dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

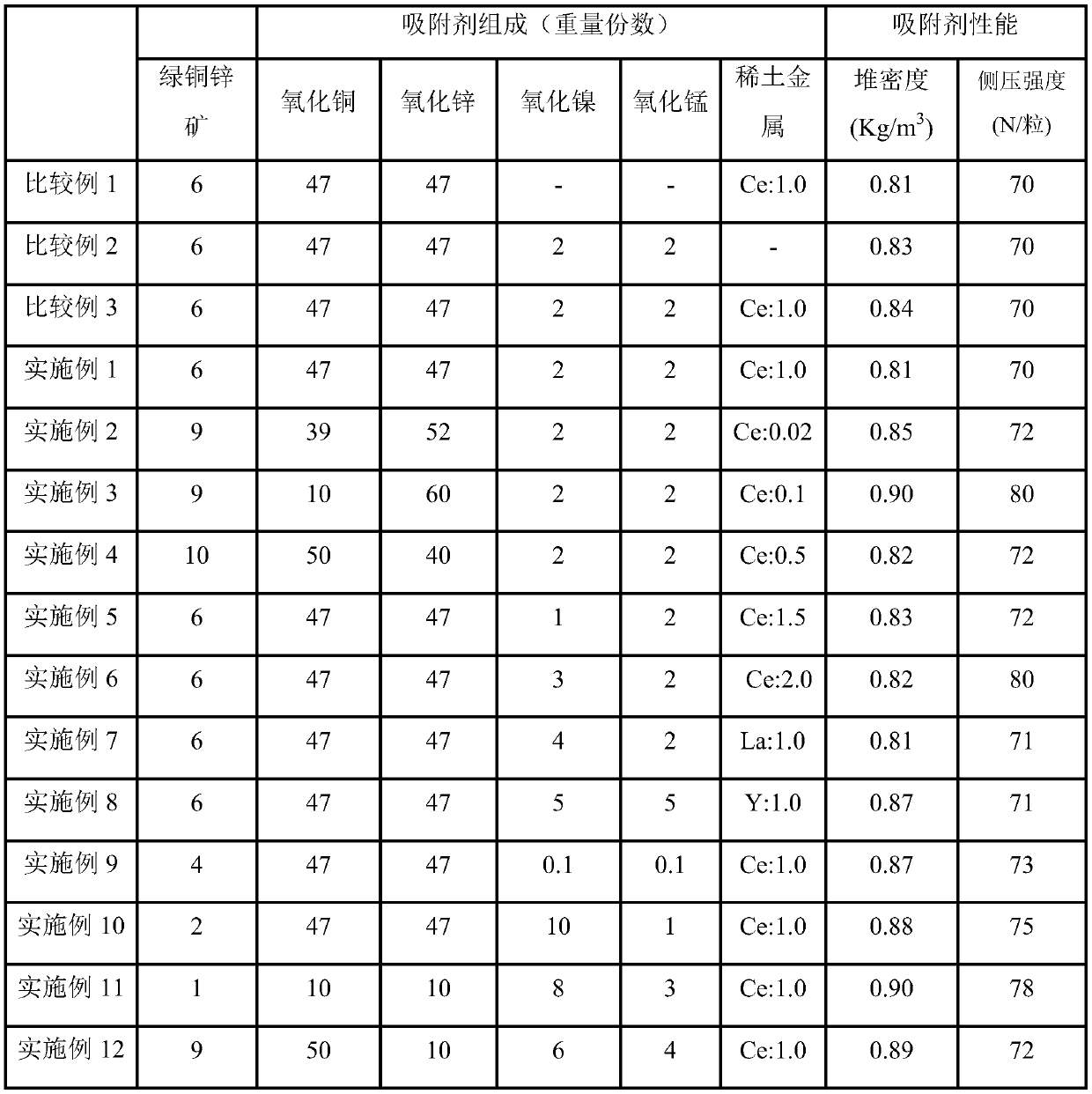

[0032]30 kg of copper nitrate trihydrate, 40 kg of zinc nitrate hexahydrate, and 500 kg of water are mixed and stirred evenly to obtain a metal salt solution, 30 kg of sodium carbonate and 550 kg of water are uniformly mixed to obtain a sodium carbonate solution, and the sodium carbonate solution is mixed with the metal salt Mix the solution evenly, react at 70°C for 1 hour, add 5 kg of pseudo-boehmite, react for 0.5 hour, wash the precipitate until the conductivity of the filtrate is less than 100 μs / cm, dry the precipitate, then add 1 kg of graphite, 30 wt. % of water was mixed and rolled, granulated, calcined at 270°C for 2 hours, and pressed into tablets. The composition of the obtained sample is shown in Table 1.

Embodiment 2

[0034] 20 kilograms of copper nitrate trihydrate, 50 kilograms of zinc nitrate hexahydrate, 1.75 kilograms of manganese nitrate 50% aqueous solution, 2.5 kilograms of nickel nitrate hexahydrate, 0.02 kilogram of cerium nitrate and 500 kilograms of water were mixed and stirred evenly to obtain a metal salt solution, and sodium carbonate 30 1 kg and 550 kg of water were mixed uniformly to obtain a sodium carbonate solution, and the sodium carbonate solution and the metal salt solution were mixed uniformly, reacted at 60°C for 2 hours, added 5 kg of pseudo-boehmite, reacted for 0.5 hours, and washed the precipitate until the filtrate The conductivity was less than 100 μs / cm, the precipitate was dried, and then 1 kg of graphite and 35% by weight of water were added, mixed and rolled, granulated, roasted at 270°C for 2 hours, and pressed into tablets. The composition of the obtained sample is shown in Table 1.

Embodiment 3

[0036] 10 kilograms of copper nitrate trihydrate, 60 kilograms of zinc nitrate hexahydrate, 1.75 kilograms of manganese nitrate 50% aqueous solution, 2.5 kilograms of nickel nitrate hexahydrate, 0.1 kilogram of cerium nitrate and 500 kilograms of water were mixed and stirred evenly to obtain a metal salt solution, and sodium carbonate 30 1 kg and 550 kg of water were mixed uniformly to obtain a sodium carbonate solution, and the sodium carbonate solution and the metal salt solution were mixed uniformly, reacted at 60°C for 2 hours, added 6 kg of pseudo-boehmite, reacted for 0.5 hours, and washed the precipitate until the filtrate The conductivity was less than 100 μs / cm, the precipitate was dried, and then 1 kg of graphite and 50% by weight of water were added, mixed and rolled, granulated, roasted at 270°C for 2 hours, and pressed into tablets. The composition of the obtained sample is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com