Scratch-proof 3D (three-dimensional) printer glass and preparation method thereof

A 3D printer, anti-scratch technology, used in additive processing and other directions, can solve problems such as cracking, affecting the reliability and safety of 3D printing equipment, and drastic changes in glass temperature, to improve wear resistance, raw materials and production pollution. The effect of low performance and low energy consumption in processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

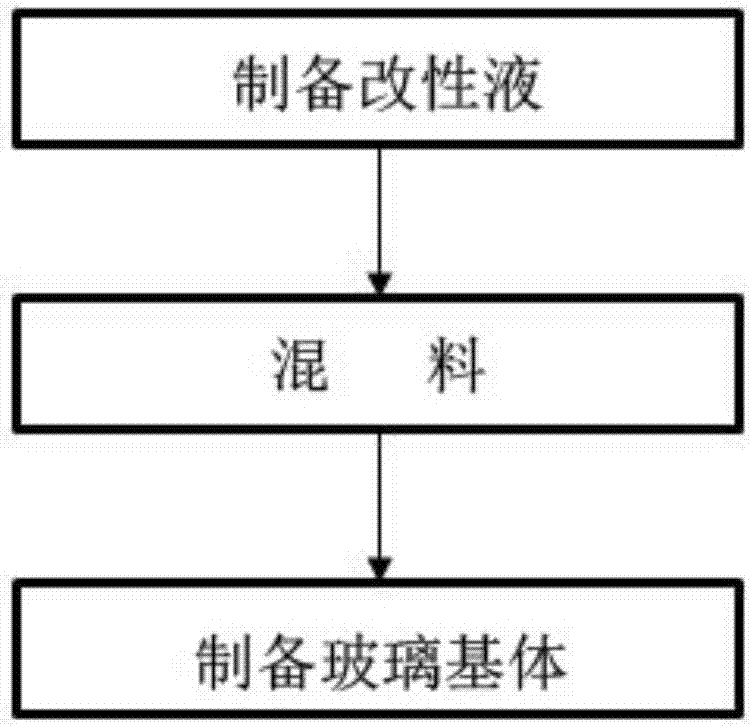

[0019] Such as figure 1 with 2 As shown, a scratch-resistant 3D printer glass is composed of the following materials in parts by mass: 6.8% of monocrystalline silicon powder, 3.5% of Avalokitesvara powder, 10% of graphene, 15% of N,N-dimethylamide, Polymethacrylate 3.5%, isopropanol 0.5%, magnesium hydroxide 0.1%, chromium oxide 0.5%, propylene glycol monobutyl ether 1.1%, and the balance is glass powder.

[0020] In this embodiment, both the monocrystalline silicon powder and Guanyin soil powder have a powder structure of 35 nm, and the glass powder has a particle structure of 150 mesh in diameter.

[0021] In the present embodiment, the amount of N,N-dimethylamide is 1.5 times of the total amount of Avalokitesvara powder and graphene.

[0022] A preparation method of anti-scratch 3D printer glass, comprising the following steps:

[0023] The first step is to prepare the modified solution, add Guanyin soil powder and graphene to N,N-dimethylamide, and then carry out ultras...

Embodiment 2

[0030] Such as figure 1 with 2 As shown, a scratch-resistant 3D printer glass is composed of the following materials in parts by mass: 4.8% of monocrystalline silicon powder, 3% of Avalokitesvara powder, 10% of graphene, 16% of N,N-dimethylamide, Polymethacrylate 3.1%, isopropanol 0.3%, magnesium hydroxide 0.2%, chromium oxide 1%, and the balance is glass powder.

[0031] In this embodiment, both the monocrystalline silicon powder and Guanyin soil powder have a powder structure of 35 nm, and the glass powder has a particle structure of 100 mesh in diameter.

[0032] In the present embodiment, the amount of N,N-dimethylamide is 3 times of the total amount of Avalokitesvara powder and graphene.

[0033] A preparation method of anti-scratch 3D printer glass, comprising the following steps:

[0034] The first step is to prepare the modified solution, add Guanyin soil powder and graphene to N,N-dimethylamide, and then carry out ultrasonic unidirectional stirring on the mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com