Product preparation and separation system for byproducts with boiling points lower than those of products and raw materials as well as treatment method and application of product preparation and preparation system

A technology for separating systems and by-products, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of unstable product quality, accelerated reaction rate, low conversion rate, etc., to shorten the reaction residence time , the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

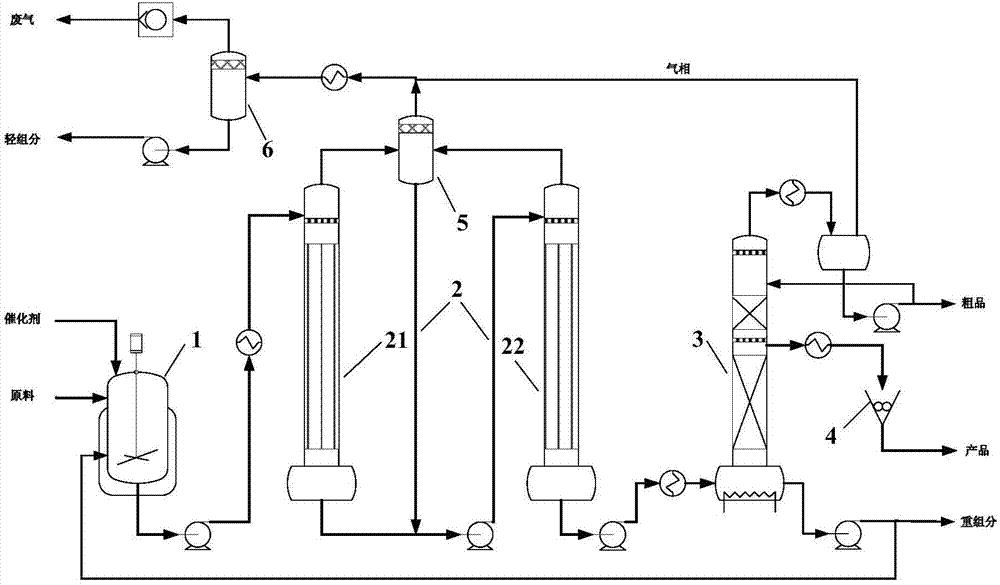

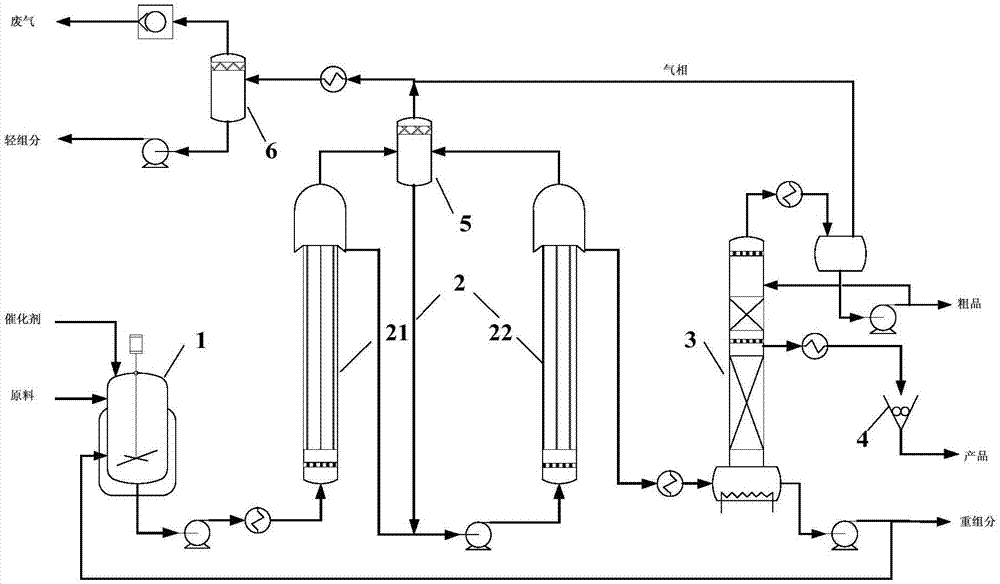

[0093] This embodiment provides a product preparation and separation system for by-products with a boiling point lower than that of products and raw materials. The system includes a light removal unit, a separation unit and a refining unit; wherein the light removal unit includes a raw material mixing device 1 and A film-forming reactor 2, the bottom outlet of the raw material mixing device 1 is connected to the feed port of the film-forming reactor 2, and the top gas outlet of the film-forming reactor 2 is connected to the separation unit , the outlet of the film-forming reactor 2 is connected with the refining unit.

Embodiment 2

[0095] This embodiment provides a method for the preparation and separation of by-products with a boiling point lower than that of the product and the raw material. The method is carried out using the system in Example 1, comprising the following steps:

[0096] (a) After the raw materials are fully mixed, light removal reaction occurs in the film-forming reactor 2;

[0097] (b) recovering the evaporated raw materials and products during the delightening reaction described in step (a) and returning to step (a) to continue the reaction, and condensing and recycling the evaporated by-products;

[0098] (c) Refining the product generated by the light removal reaction in step (a) to obtain a refined product, and returning the remaining solution to step (a) as a recycle material to continue the reaction.

Embodiment 3

[0100] This embodiment provides a system for the continuous catalytic dehydration of sorbitol to prepare isosorbide, such as figure 1 As shown, the system includes a sorbitol dehydration unit, a vacuum separation unit and an isosorbide refining unit; wherein, the sorbitol dehydration unit includes a raw material mixing device 1 and a falling film reactor 2, and the raw material mixing device 1 bottom The discharge port is connected with the upper feed port of the falling film reactor 2, the top gas outlet of the falling film reactor 2 is connected with the vacuum separation unit, and the bottom outlet of the falling film reactor 2 is The feed port is connected with the isosorbide refining unit.

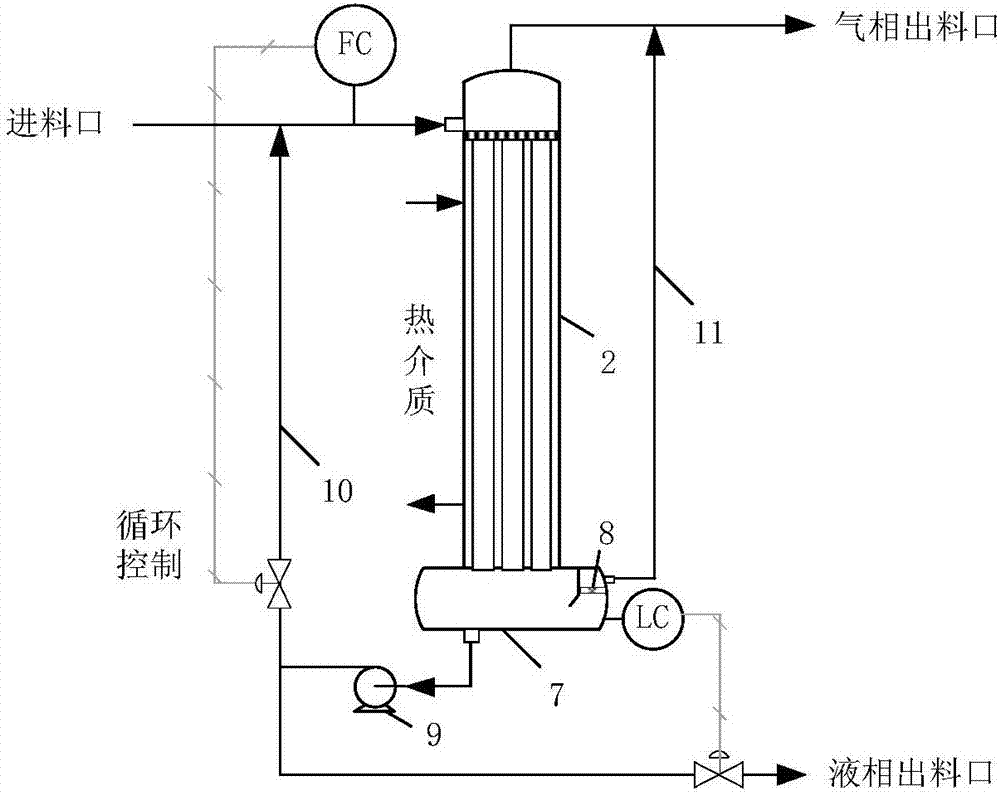

[0101] Wherein, the raw material mixing device 1 is provided with a heating device, the falling film reactor 2 is provided with a heating device and a material circulation system, and the falling film reactor 2 is a first-stage falling film reactor 21 and The secondary falling film r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com