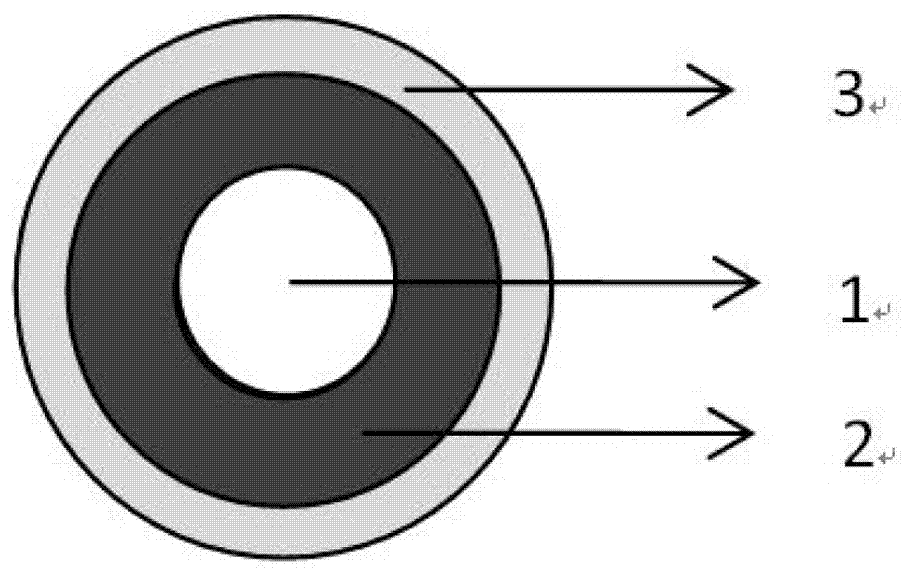

Graphene/organic-matter composite particles and preparation method thereof

A technology of composite particles and organic matter, applied in the direction of coating, etc., can solve problems such as adhesion, clogging, and low quality, and achieve the effects of easy implementation, simple process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

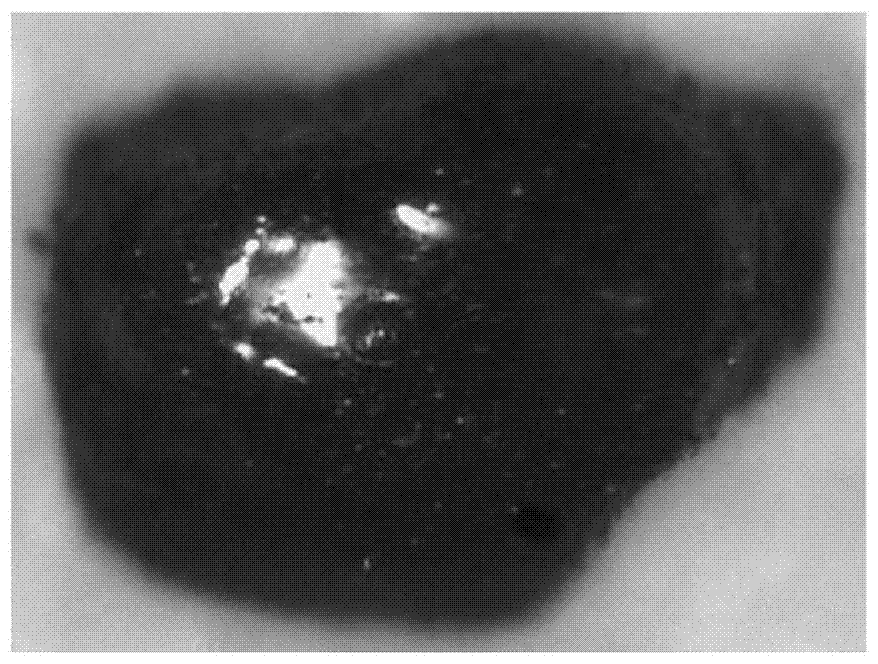

Examples

Embodiment 1

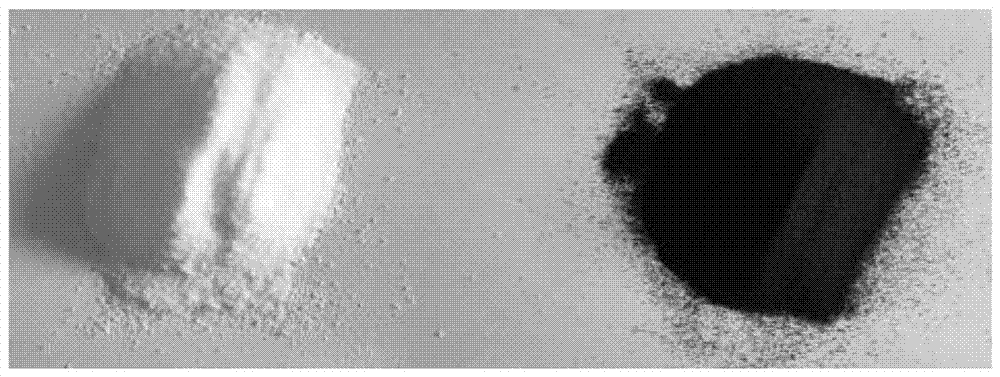

[0026] (1) Weigh 620 grams of 500-mesh polylactic acid particles, put them into a low-temperature argon plasma processor, set the power to 90W, vacuumize to 15Pa, and treat the low-temperature argon plasma for 9 minutes. After cooling, Take it out and set aside.

[0027] (2) Weigh a carbon content of 99.5% and a specific surface area of 400m 2 20 grams / g graphene powder, stand-by.

[0028] (3) First add part (one-third of the mass) of organic particles that have been treated with low-temperature argon plasma into the ceramic tank, then add part (one-third of the mass) of graphene powder, and then add part (three One-half of the mass) fused corundum grinding balls are added to it, and the above process is repeated until the addition of organic particles and graphene powder is complete. Ball milling for 4 hours at a rotational speed of 300 r / min to obtain a graphene / organic compound particle preform.

[0029] (4) Sieve the ball-milled graphene / organic compound particle pref...

Embodiment 2

[0034] (1) Weigh 500 grams of 900-mesh polyethylene particles, put them into a low-temperature argon plasma processor, set the power at 120W, vacuumize to 25Pa, and treat with low-temperature argon plasma for 6 minutes. After cooling, take out stand-by.

[0035] (2) Weigh a carbon content of 99.5% and a specific surface area of 600m 2 45 grams / g graphene powder, stand-by.

[0036] (3) First add part (one-third of the mass) of organic particles that have been treated with low-temperature argon plasma into the ceramic tank, then add part (one-third of the mass) of graphene powder, and then add part (three One-half of the mass) fused corundum grinding balls are added to it, and the above process is repeated until the addition of organic particles and graphene powder is complete. Ball milling for 3 hours at a rotational speed of 250r / min to obtain a graphene / organic compound particle preform.

[0037] (4) The ball-milled graphene / organic compound particle preform is sieved with...

Embodiment 3

[0041] (1) Weigh 600 grams of 500-mesh polystyrene particles, put them into a low-temperature argon plasma processor, set the power to 150W, vacuumize to 30Pa, and process the low-temperature argon plasma for 3 minutes. After cooling, Take it out and set aside.

[0042] (2) Weigh a carbon content of 99.5% and a specific surface area of 350m 2 20 grams / g graphene powder, stand-by.

[0043] (3) First add part (one-third of the mass) of organic particles that have been treated with low-temperature argon plasma into the ceramic tank, then add part (one-third of the mass) of graphene powder, and then add part (three One-half of the mass) fused corundum grinding balls are added to it, and the above process is repeated until the addition of organic particles and graphene powder is complete. After ball milling at 250r / min for 4 hours, the graphene powder is adsorbed and mechanically occluded on the surface of the organic particles to obtain a graphene / organic composite particle pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com