Method of preparing alpha-ketoamide with micro-reaction apparatus

A micro-reaction device and ketamide technology, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low solubility and blocked reaction pipelines, and achieve strong mass transfer capacity and low side reactions. , The effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

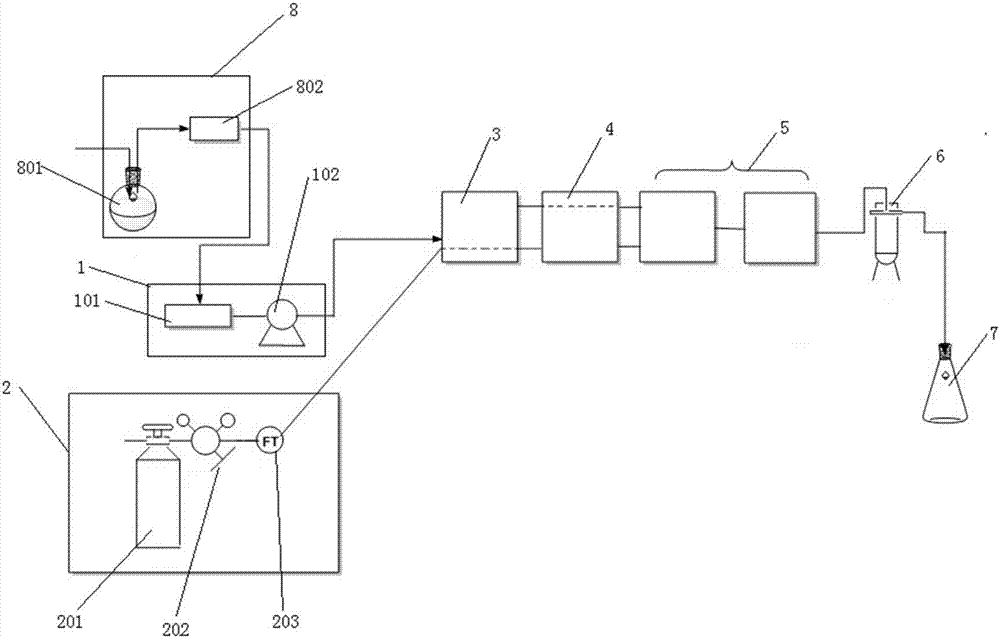

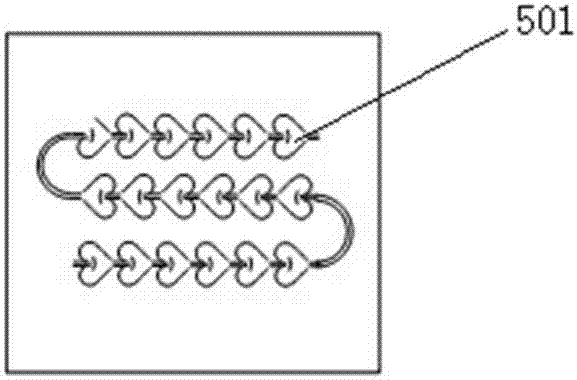

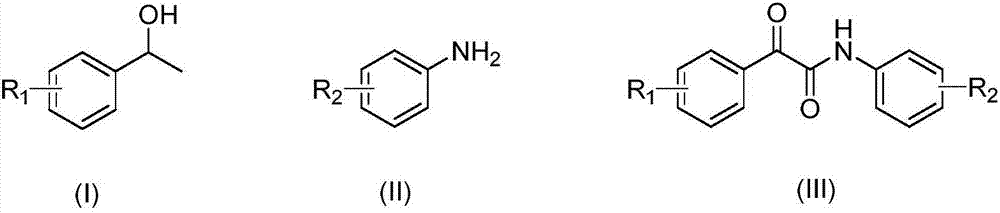

[0037] use figure 1Preparation of α-ketoamide with a micro-reaction device: Weigh 1 g (0.006 mol) of ferric chloride powder and 7.7 g (0.048 mol) of 2,2'-bipyridine in a tank reaction filled with 30 mL of dichloromethane In the container, it is the raw material A, the heating temperature is 30 ° C, and the reaction is carried out for 3 hours. After the reaction, the reaction liquid is filtered through a filter to obtain a clear liquid. Weigh 1.25g (0.008mol) of 2,2,6,6,-tetramethylpiperidine oxide, 12.31g (0.1mol) of α-methylbenzyl alcohol, 11.81g (0.1mol) of p-aminobenzene Nitrile and 15.82g (0.2mol) of pyridine were dissolved in 60mL of dichloromethane, which was raw material B. Stir and mix the clear liquid and raw material B in the liquid storage tank to obtain a mixed liquid, feed nitrogen back pressure to 10 bar into the Corning reactor, switch to oxygen, and pump the mixed liquid into the Corning reactor at the same time. Keep the reaction temperature at 40°C, the flo...

Embodiment 2

[0039] The preparation method is the same as in Example 1, except that the heating temperature of ferric chloride powder and 2,2'-bipyridine in the tank reactor is 45°C, and the reaction is carried out for 3 hours. Through high-performance liquid chromatography analysis, in this reaction, the conversion rate of the α-ketoamide products generated is 94%.

Embodiment 3

[0041] The preparation method is the same as in Example 1, except that the reaction temperature in the Corning reactor is 45°C. According to high-performance liquid chromatography analysis, in this reaction, the conversion rate of the α-ketoamide products generated is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com