Method for determining content of microplastics in seawater and organism-absorbed microplastics

A determination method and microplastic technology, applied in the field of environmental pollutant detection, can solve the problems of complex operation steps, high measurement cost, inability to know the relationship between microplastics content and microplastics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

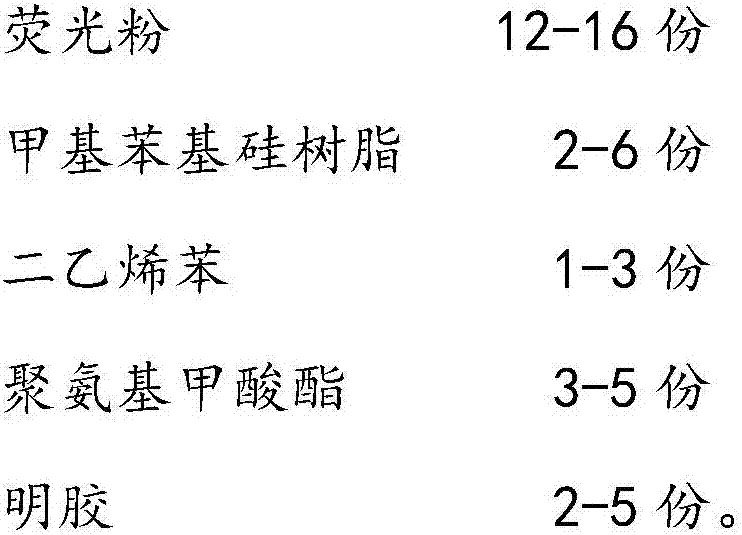

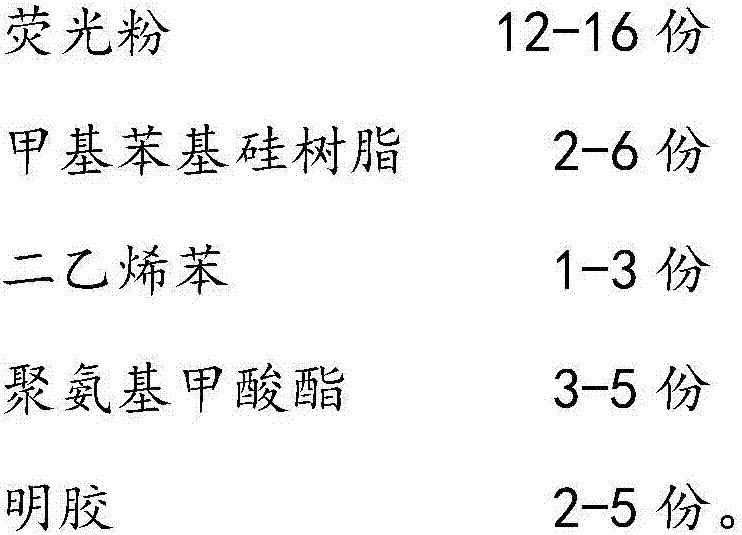

[0031] Step 1. Stir 3 parts of methylphenyl silicone resin, 3 parts of polyurethane and 12 parts of calcium halophosphate phosphor at 120° C. for 40 minutes to form a mixture M1;

[0032] Step 2. Add 1.5 parts of divinylbenzene to the mixture M1, and stir at 100° C. for 30 minutes to form a mixture M2;

[0033] Step 3: Add 2 parts of gelatin to the mixture M2 at 60°C, and stir for 40 minutes to form a mixture M3;

[0034] Step 4. After drying the mixture M3, grind and sieve to make a powder with a diameter of 0.5mm-1.2mm to obtain a viscous phosphor material.

Embodiment 2

[0036] Step 1. Stir 5.8 parts of methylphenyl silicone resin, 4.5 parts of polyurethane and 16 parts of calcium halophosphate phosphor at 130° C. for 45 minutes to form a mixture M1;

[0037] Step 2. Add 2.5 parts of divinylbenzene to the mixture M1, and stir at 110° C. for 35 minutes to form a mixture M2;

[0038] Step 3: Add 5 parts of gelatin to the mixture M2 at 65°C, and stir for 45 minutes to form a mixture M3;

[0039] Step 4. After drying the mixture M3, grind and sieve to make a powder with a diameter of 0.5mm-1.2mm to obtain a viscous phosphor material.

Embodiment 3

[0041] Step 1. Stir 4.5 parts of methylphenyl silicone resin, 6 parts of polyurethane and 13 parts of calcium halophosphate phosphor at 125°C for 50 minutes to form a mixture M1;

[0042] Step 2. Add 3 parts of divinylbenzene to the mixture M1, and stir at 100° C. for 35 minutes to form a mixture M2;

[0043] Step 3: Add 4.5 parts of gelatin to the mixture M2 at 70°C, and stir for 50 minutes to form a mixture M3;

[0044] Step 4. After drying the mixture M3, grind and sieve to make a powder with a diameter of 0.5mm-1.2mm to obtain a viscous phosphor material.

[0045] In the above-mentioned embodiment, methyl phenyl silicone resin, polyurethane and gelatin are used to react with fluorescent powder at high temperature, and an adhesive film can be formed on the surface of fluorescent powder, which can resist polyethylene, polypropylene , polyvinyl chloride, polystyrene, polyurethane, polyamide, polyethylene terephthalate and other microplastics have good selective binding effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com