Surface in-situ modified polyquaternary ammonium functional group mesoporous silicon dioxide material, as well as a preparation method and application thereof

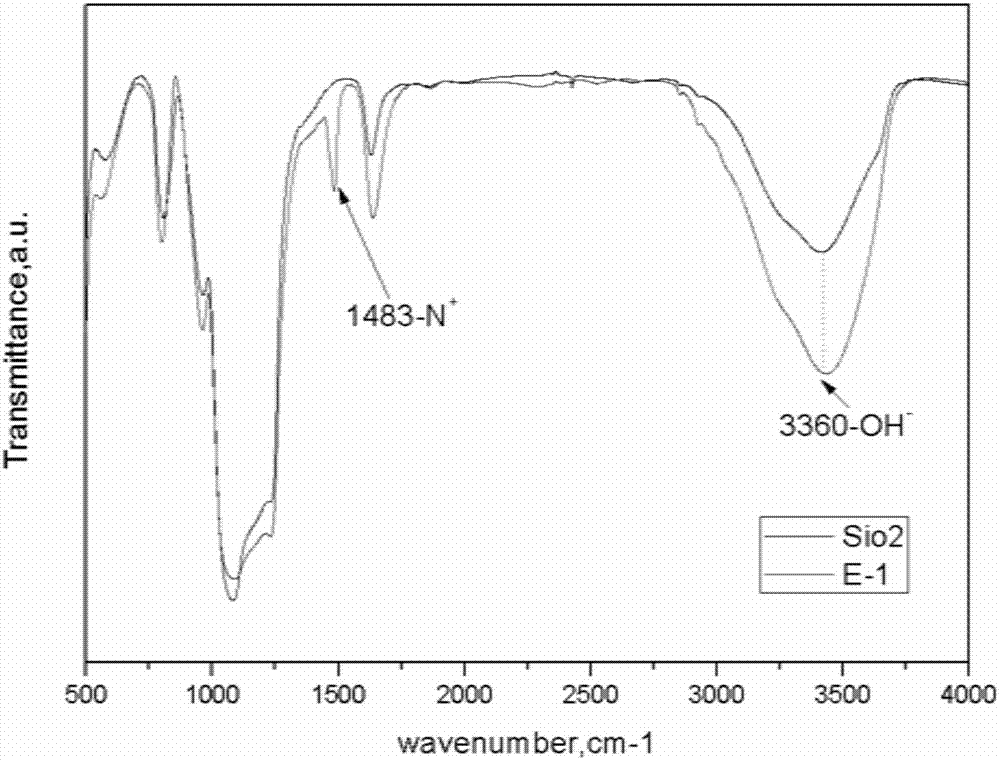

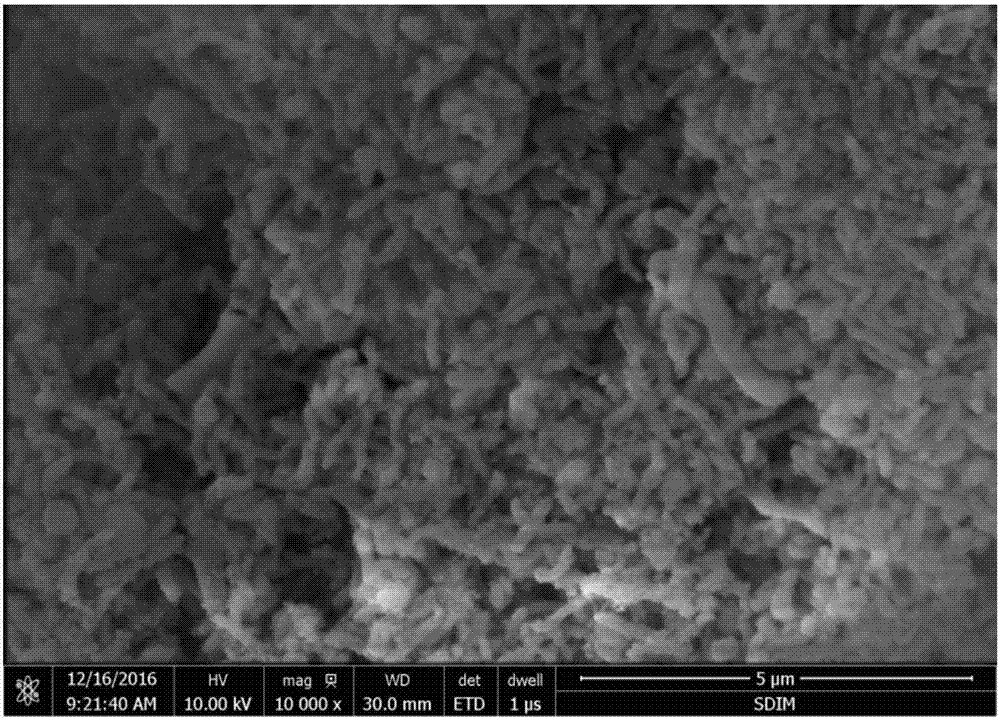

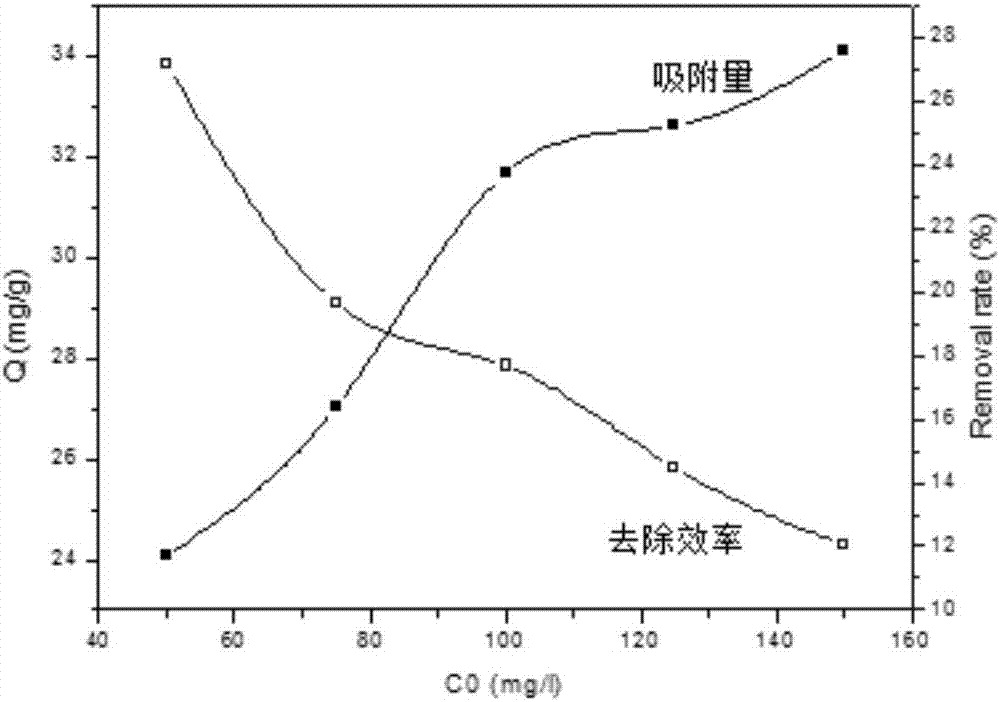

A technology of mesoporous silica and in-situ modification, applied in the fields of chemistry and environment, can solve the problem of high cost and achieve the effects of increasing molecular weight, enhancing electrostatic affinity and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a mesoporous silica material whose surface is in-situ modified with polyquaternary ammonium functional groups, the steps are as follows:

[0039] (1) Add 140ml of deionized water and 5ml of ammonia water (NH 3 .H 2 O), then add 1.5g template agent hexadecyltrimethylammonium bromide, after stirring for 30min under 50°C water bath condition. Slowly add 6.7ml silicon source tetraethyl orthosilicate dropwise into the three-necked flask, stir and react for 4 hours, then ultrasonically clean, then deionized water and absolute ethanol three times respectively, and suction dry. Put the dried sample into a muffle furnace, raise the temperature to 550°C, and calcine at this temperature for 5 hours to remove the template agent, and the white product is mesoporous silica material MCM-41, which is sealed for future use.

[0040] (2) Add 2g of cationic functionalization reagent polyepichlorohydrin dimethylamine (EPI-DMA) and 100g of deionized water into a 250...

Embodiment 2

[0044] A method for preparing a mesoporous silica material whose surface is in-situ modified with polyquaternary ammonium functional groups, the steps are as follows:

[0045] (1) Add 140ml of deionized water and 5ml of ammonia water (NH 3 .H 2 O), then add 1.5g template agent hexadecyltrimethylammonium bromide, after stirring for 30min under 50°C water bath condition. Slowly add 6.7ml silicon source tetraethyl orthosilicate dropwise into the three-necked flask, stir and react for 4 hours, then ultrasonically clean for 10 minutes, then wash three times with deionized water and absolute ethanol in turn, and dry by suction. Put the dried sample into a muffle furnace, raise the temperature to 550°C, and calcine at this temperature for 5 hours to remove the template agent, and the white product is mesoporous silica material MCM-41, which is sealed for future use.

[0046] (2) Add 4g of cationic functionalization reagent polyepichlorohydrin dimethylamine (EPI-DMA) and 100g of dei...

Embodiment 3

[0050] A method for preparing a mesoporous silica material whose surface is in-situ modified with polyquaternary ammonium functional groups, the steps are as follows:

[0051] (1) Add 140ml of deionized water and 5ml of ammonia water (NH 3 .H 2 O), then add 1.5g template agent hexadecyltrimethylammonium bromide, after stirring for 30min under 50°C water bath condition. Slowly add 6.7ml silicon source tetraethyl orthosilicate dropwise into the three-necked flask, stir and react for 4 hours, then ultrasonically clean for 10 minutes, then wash three times with deionized water and absolute ethanol in turn, and dry by suction. Put the dried sample into a muffle furnace, raise the temperature to 550°C, and calcine at this temperature for 5 hours to remove the template agent, and the white product is mesoporous silica material MCM-41, which is sealed for future use.

[0052] (2) Add 10 g of cationic functionalization reagent polyepichlorohydrin dimethylamine (EPI-DMA) and 100 g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com