Preparation method for phosphorus fertilizer with high utilization rate

A utilization rate and phosphate fertilizer technology, applied in application, organic fertilizer, fertilization device, etc., can solve problems such as difficult chelation phosphate, insufficient available phosphorus, soil compaction, etc., to achieve increased air permeability, improved utilization rate, and sufficient absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

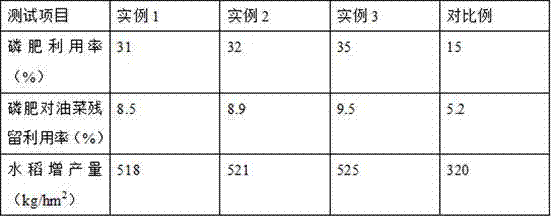

Examples

example 1

[0024]Weigh 0.1kg peeled sweet potato and cut into pieces and put it into a beaker with 0.8L deionized water. After boiling for 16 min, the boiled sweet potato is obtained. Filter the boiled sweet potato with 2 layers of gauze, remove the filter residue, and obtain the self-made filtrate. Add the self-made filtrate into a beaker with 0.5% of the self-made filtrate quality sucrose and 6% of the self-made filtrate quality deionized water, mix and stir for 20min, and sterilize in a pressure steam sterilizer at 100°C for 30min to obtain the self-made medium 1 , insert the Aspergillus niger strain into the self-made medium 1 according to the inoculation amount of 10%, and cultivate it for 5 days at 25°C to obtain the bacterial liquid matrix 1. In parts by weight, 10 parts of peptone and 10 parts of Pork paste and 6 parts of yogurt were mixed and stirred in a blender for 10 minutes. After stirring, 3 parts of dipotassium hydrogen phosphate, 2 parts of sodium alkyd, 4 parts of sucrose...

example 2

[0026] Weigh 0.1kg peeled sweet potato and cut into pieces and put it into a beaker with 0.9L deionized water. After boiling for 18min, the boiled sweet potato is obtained. The boiled sweet potato is filtered with 2 layers of gauze, and the filter residue is removed to obtain the self-made filtrate. The self-made filtrate was added into a beaker with 0.5% of the self-made filtrate quality sucrose and 6% of the self-made filtrate quality deionized water, mixed and stirred for 25min, and sterilized in a pressure steam sterilizer at 110°C for 35min to obtain the self-made medium 1, Insert the Aspergillus niger strain into the self-made medium 1 according to the inoculation amount of 10%, and cultivate it at 30°C for 6 days to obtain the bacterial liquid matrix 1. In parts by weight, 15 parts of peptone and 15 parts of pork The cream and 8 parts of yogurt were mixed and stirred in a blender for 11 minutes, and then added 4 parts of dipotassium hydrogen phosphate, 3 parts of sodium ...

example 3

[0028] Take by weighing 0.2kg peeled sweet potato and cut into pieces and put it into a beaker with 1.0L deionized water. After boiling for 20 min, the boiled sweet potato is obtained. Filter the boiled sweet potato with 3 layers of gauze, remove the filter residue, and obtain the self-made filtrate. Add the self-made filtrate into a beaker with 0.5% of the self-made filtrate quality sucrose and 6% of the self-made filtrate quality deionized water, mix and stir for 30min, and sterilize in a pressure steam sterilizer at 120°C for 45min to obtain the self-made medium 1 , insert the Aspergillus niger strain into the self-made culture medium 1 according to the inoculation amount of 10%, and cultivate it for 7 days at 35°C to obtain the bacterial liquid matrix 1. In parts by weight, 20 parts of peptone and 20 parts of Pork paste and 10 parts of yogurt were mixed and placed in a blender for 12 minutes, and then 5 parts of dipotassium hydrogen phosphate, 4 parts of sodium alkyd, 6 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com