Isobutene-maleic anhydride alternating copolymer/sodium alginate hydrogel and preparation method thereof

A technology of alternating copolymers and sodium alginate, which is applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of limiting the use of sodium alginate gel, single cross-linking method, and severe water separation, and achieves The effect of controllable cost, simple process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

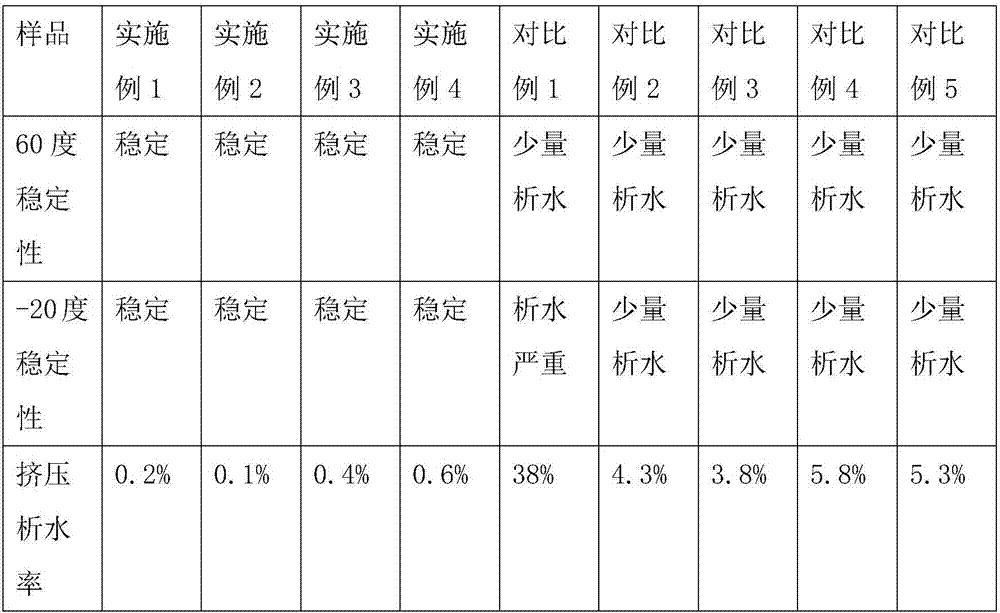

Examples

Embodiment 1

[0030] A kind of embodiment of the present invention comprises each raw material and component of following percentage by weight:

[0031] 4% sodium alginate with a viscosity of 200cps, 1.5% calcium sulfate hemihydrate, 2.0% sodium hexametaphosphate, 6% amide-ammonium salt type isobutylene-maleic anhydride alternating copolymer with a number average molecular weight of 170,000, 0.6% preservative, and the balance is water composition.

Embodiment 2

[0033] A kind of embodiment of the present invention comprises each raw material and component of following percentage by weight:

[0034] 6% sodium alginate with a viscosity of 400cps, 2.5% calcium sulfate dihydrate, 1.5% sodium tripolyphosphate, 4% amide-ammonium salt type isobutylene-maleic anhydride alternating copolymer with a number average molecular weight of 165,000, 1.2% preservative, and the balance is water composition.

Embodiment 3

[0036] A kind of embodiment of the present invention comprises each raw material and component of following percentage by weight:

[0037] 2.5% sodium alginate with a viscosity of 600cps, 1.2% calcium sulfate hemihydrate, 1.6% sodium hexametaphosphate, 2% amide-ammonium salt type isobutylene-maleic anhydride alternating copolymer with a number average molecular weight of 168,000, 0.3% preservative, and the balance is water composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com