Preparation method of low corrosivity snow melting agent

A corrosive and deicing agent technology, applied in the field of preparation of low corrosive deicing agents, can solve problems affecting plant growth, polluting water bodies, human health and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

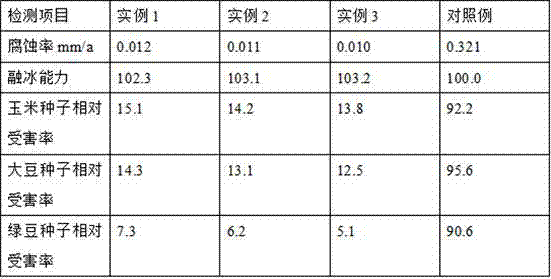

Examples

example 1

[0022] Collect the discarded duck oil that drips during the roasting process of the duck shop, pour the duck oil into a stainless steel tray, and then move the tray into a greenhouse with a temperature of 30°C and a relative air humidity of 60%, and let it stand for 10 days to make it rancid naturally Moldy, get rancidity, set aside; weigh lemon, konjac and grapes according to the mass ratio of 5:3:1, put them in a mortar, grind and pulverize for 30min, to obtain mixed pulverization, mix the pulverization with yogurt and concentration of 10 5 The cfu / mL Bacillus subtilis suspension is mixed according to the mass ratio of 10:2:1, then put into the fermenter as the fermentation substrate, then add water of the same quality as the fermentation substrate into the fermenter, stir evenly, and seal The fermenter was sealed and fermented at 35°C for 10 days; after the fermentation was completed, the fermenter was opened, the fermentation product was taken out and filtered, and the ferm...

example 2

[0024] Collect the discarded duck oil that drips during the roasting process of the duck shop, pour the duck oil into a stainless steel tray, and then move the tray into a greenhouse with a temperature of 35°C and a relative air humidity of 65%, and let it stand for 13 days to make it rancid naturally Moldy, get rancidity, set aside; weigh lemon, konjac and grapes according to the mass ratio of 5:3:1, put them in a mortar, grind and pulverize for 35min, to obtain mixed pulverization, mix the pulverization with yogurt and concentration of 10 5 The cfu / mL Bacillus subtilis suspension is mixed according to the mass ratio of 10:2:1, then put into the fermenter as the fermentation substrate, then add water of the same quality as the fermentation substrate into the fermenter, stir evenly, and seal The fermenter was sealed and fermented at 40°C for 11 days; after the fermentation was completed, the fermenter was opened, the fermentation product was taken out and filtered, and the ferm...

example 3

[0026]Collect the discarded duck oil that drips during the roasting process of the duck shop, pour the duck oil into a stainless steel tray, and then move the tray into a greenhouse with a temperature of 40°C and a relative air humidity of 70%, and let it stand for 15 days to make it rancid naturally Moldy, get rancidity, set aside; weigh lemon, konjac and grapes according to the mass ratio of 5:3:1, put them in a mortar, grind and pulverize for 40min, to obtain mixed pulverization, mix the pulverization with yogurt and concentration of 10 5 The cfu / mL Bacillus subtilis suspension is mixed according to the mass ratio of 10:2:1, then put into the fermenter as the fermentation substrate, then add water of the same quality as the fermentation substrate into the fermenter, stir evenly, and seal Fermentation tank, sealed and fermented at 45°C for 12 days; after the fermentation is over, open the fermenter, take out the fermentation product and filter, separate the fermentation filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com