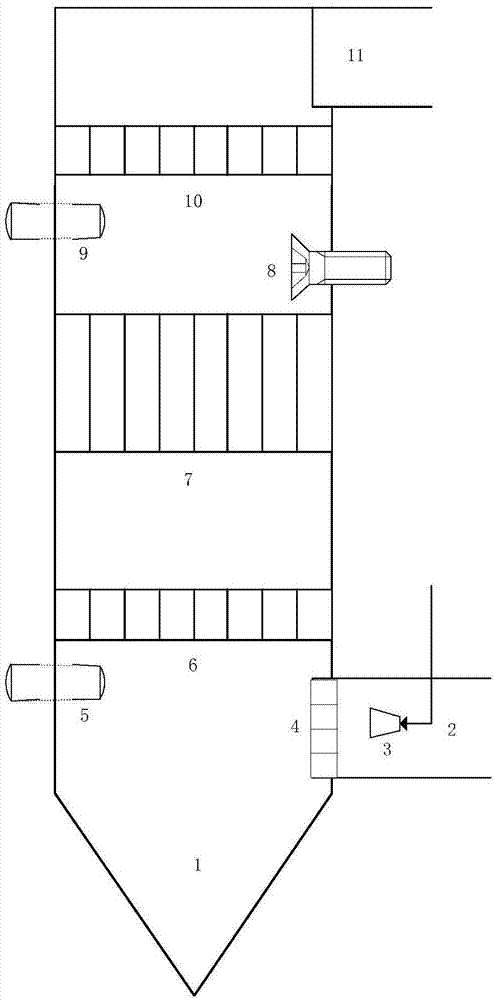

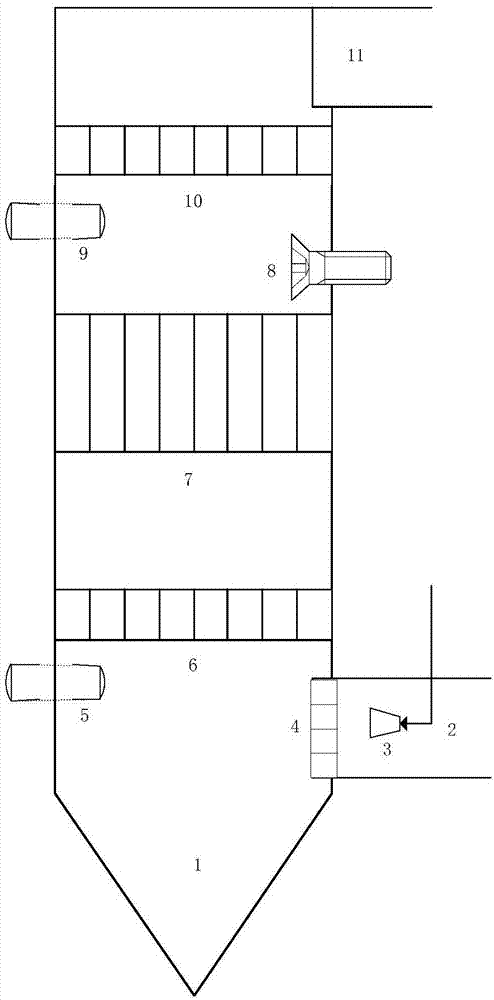

Denitration system for removing nitrogen oxide in sintering flue gas and flue gas denitration method

A technology for sintering flue gas and nitrogen oxides, which is applied in the fields of flue gas treatment and environmental engineering, can solve the problems of high investment and operating costs, high operating temperature CO, waste of resources, etc., to save transportation and storage costs, reduce Investment costs and operating costs, the effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

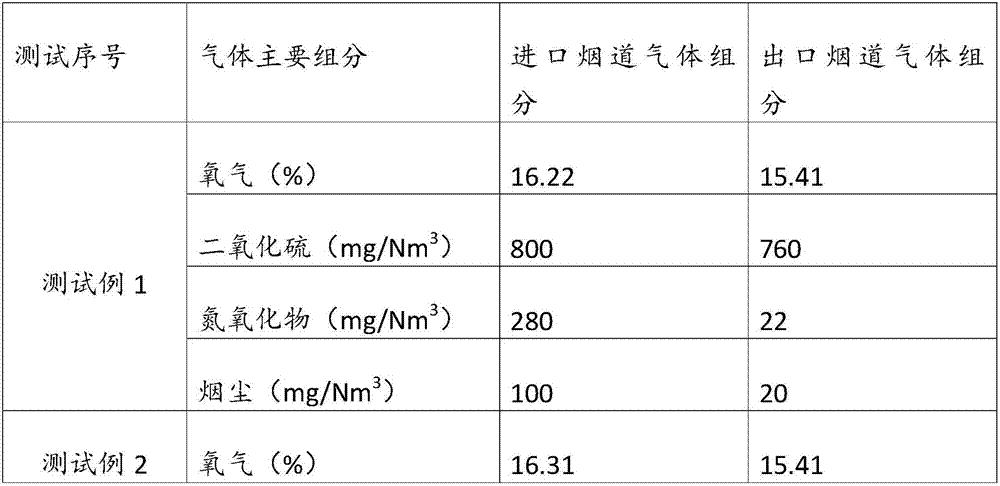

[0051] Raw gas composition: oxygen 16.2%, nitrogen 68.39%, water 10.2%, carbon dioxide 5.2%, sulfur dioxide 800㎎ / Nm 3 , nitrogen oxides 280㎎ / Nm 3 , soot content 100㎎ / Nm 3 .

[0052] Denitration agent composition: hydrogen 60.15%, oxygen 0.07%, carbon monoxide 6.45%, methane 21.24%, carbon dioxide 1.82%, CnHm 2.44%, nitrogen 7.83%, calorific value 3916Kcal / Nm 3

[0053] The flue gas temperature at the inlet of the denitrification system is 150°C, and the gas flow rate is 60,000m 3 / h. After the detection and analysis of the online detection equipment installed at the outlet of the denitrification tower, the main components of the outlet gas are as follows: Oxygen: 16.36% Sulfur dioxide: 760㎎ / Nm 3 Nitrogen oxides: 22㎎ / Nm 3 Soot content: 20㎎ / Nm 3 .

Embodiment 2-4

[0055] The process flow and steps are the same as in Example 1. The flue gas flow rate and main flue gas components of each embodiment remain unchanged, and the temperature and pressure conditions controlled by the system remain unchanged. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com