A kind of preparation method of polyvinyl chloride special resin modified by supramolecular quadruple hydrogen bond upy unit

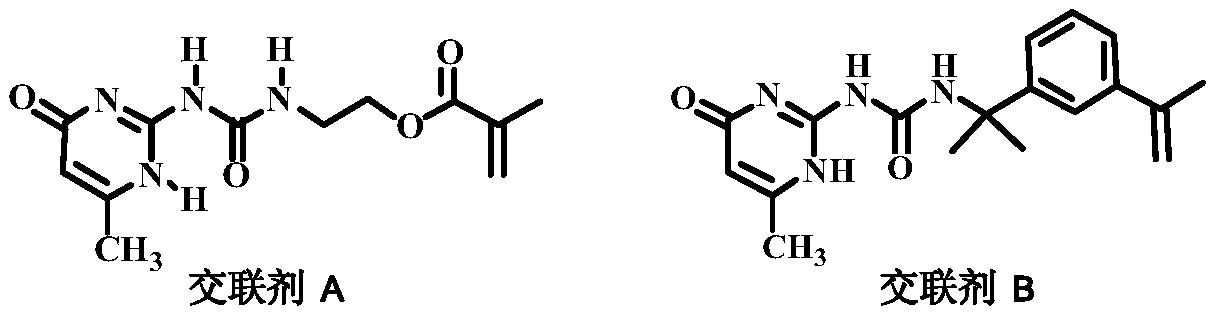

A technology of quadruple hydrogen bond and polyvinyl chloride, which is applied in the field of preparation of supramolecular quadruple hydrogen bond UPy unit modified polyvinyl chloride special resin, which can solve the problem of unstable product quality, cross-linked polyvinyl chloride, cross-linking agent dispersion Inhomogeneity, easy to produce gel particles and other problems, to achieve the effect of easy processing, strong self-aggregation ability, and self-repairing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Rinse the polymerization kettle clean, add 100% deionized water into the reaction polymerization kettle, start stirring, add dispersant polyvinyl alcohol / hydroxypropyl methylcellulose 0.03%, containing supramolecular quadruple hydrogen bond UPy unit Cross-linking agent is cross-linking agent A0.005%, initiator peroxydicarbonate (2-ethylhexyl) 0.01%, buffering agent ammonium bicarbonate 0.01%, puts on the still lid, vacuumizes and discharges the air in the still, then Press in 100 parts of vinyl chloride monomer, stir for 10 minutes, then heat up to the polymerization temperature of 55°C, keep the temperature constant, and control the reaction time for 6 hours;

[0036] b. When the reaction pressure drops to the control point of 0.15MPa, add 0.01% of the terminator acetone thiosemicarbazone, continue to stir for 10 minutes, and discharge the slurry. The slurry is centrifuged, dried, and sieved to obtain a special resin for modified polyvinyl chloride.

Embodiment 2

[0038]a. Rinse the polymerization kettle clean, add 100% deionized water into the reaction polymerization kettle, start stirring, add dispersant polyvinyl alcohol / hydroxypropyl methylcellulose 0.03%, containing supramolecular quadruple hydrogen bond UPy unit Cross-linking agent is cross-linking agent A0.005%, initiator peroxydicarbonate (2-ethylhexyl) 0.01%, buffering agent ammonium bicarbonate 0.01%, puts on the still lid, vacuumizes and discharges the air in the still, then Press in 100 parts of vinyl chloride monomer, stir for 10 minutes, then heat up to the polymerization temperature of 60°C, keep the temperature constant, and control the reaction time for 8 hours;

[0039] b. When the reaction pressure drops to the control point of 0.15MPa, add 0.01% of the terminator acetone thiosemicarbazone, continue to stir for 10 minutes, and discharge the slurry. The slurry is centrifuged, dried, and sieved to obtain a special resin for modified polyvinyl chloride.

Embodiment 3

[0041] a. Rinse the polymerization kettle clean, add 100% deionized water in the reaction polymerization kettle, start stirring, add dispersant polyvinyl alcohol / hydroxypropyl methylcellulose 0.08%, initiator peroxydicarbonic acid (2-ethyl Acetyl hexyl ester) 0.1%, buffer agent ammonium bicarbonate 0.1%, put on the lid of the kettle, evacuate the air in the kettle, then press 100 parts of vinyl chloride monomer, stir for 10min and then heat up to the polymerization temperature of 55°C, constant temperature, control The reaction time is 7 hours, and the cross-linking agent containing the supramolecular quadruple hydrogen bond UPy unit is continuously and uniformly added into the kettle as the cross-linking agent A 0.01%;

[0042] b. When the reaction pressure drops to the control point pressure, add 0.01% terminator acetone thiosemicarbazone, continue to stir for 10 minutes, and discharge the slurry. The slurry is centrifuged, dried, and sieved to obtain a special resin for modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com