Blackberry wine capable of delaying cell ageing and production method of blackberry wine

A technology of cell aging and production method, which is applied in the field of food processing to achieve the effects of delaying cell aging, increasing health care functions, and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

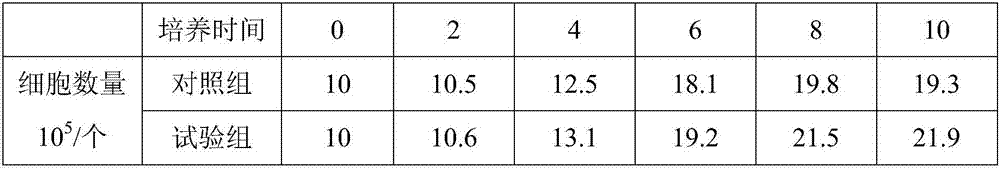

Examples

Embodiment 1

[0029] Get blackberry 8kg, fresh wolfberry 2kg and ginkgo leaf 0.1kg, after washing, breaking, beating, allocating, add pectinase 2.02g (addition amount 0.02%), potassium metabisulfite 1.01g (addition amount 0.01%) and Yeast RC212 8.08g (addition amount 0.08%, Shanghai Jietu Industry and Trade Co., Ltd.) was fermented at 15°C. When the fermentation reached a sugar content of 40g / L, 8.08g of yeast RC212 (0.08%) was added again, and the temperature was raised to 30°C for secondary fermentation, during which oxygenation and mixing were performed every 2 hours. The yeast added for the second time was pre-activated in an activation solution containing 3% inulin, 0.01% ammonium bisulfite and 4% glucose at 30°C for 1 hour, the amount of oxygen added was 2.0 mg / L, and the mixing method for each time was The mixing time was 5 minutes. When the sugar content is below 4g / L during fermentation, the temperature is raised rapidly to 35°C and kept for 3 hours, and at the same time ultrasoni...

Embodiment 2

[0041] Take 100kg of blackberries, 10kg of fresh wolfberry and 2kg of ginkgo leaves, wash, crush, beat, and blend, then add 56g of pectinase (0.05%), 8.96g of potassium metabisulfite (0.008%) and yeast RC212 56g (addition amount 0.05%, Shanghai Jietu Industry and Trade Co., Ltd.), fermented at 20°C. When the fermentation reached a sugar content of 50g / L, 56g of yeast RC212 (0.05%) was added again, and the temperature was raised to 35°C for secondary fermentation, during which oxygenation and mixing were performed every 3 hours. The yeast added for the second time was pre-activated in an activation solution containing 6% inulin, 0.03% ammonium bisulfite and 5% glucose at 35°C for 0.5h, and the amount of oxygen added was 3.0mg / L. The mixing time is 10min. When the sugar content is below 4g / L during fermentation, the temperature is raised rapidly to 38°C and kept for 2 hours, and at the same time ultrasonic treatment is carried out, and the ultrasonic intensity is 20W / cm 2 , Ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com