Roof cover plate for makeshift house

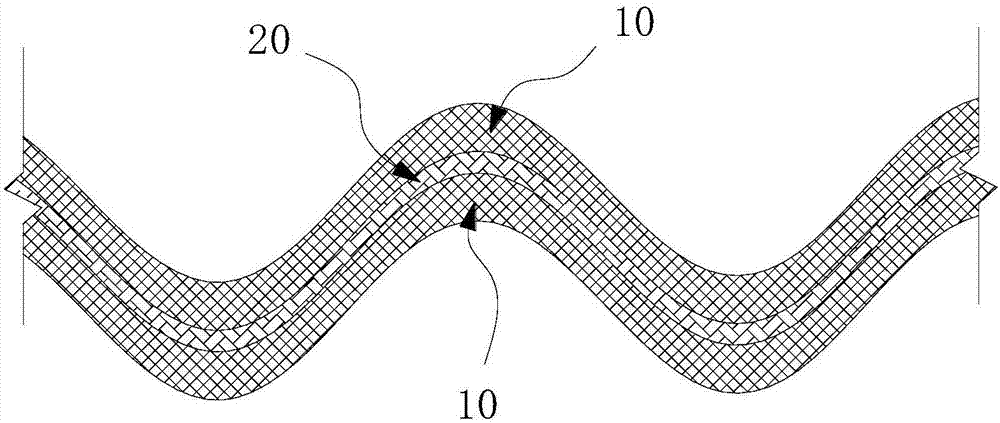

A cover plate, a simple technology, applied in the direction of the roof, roof covering layer, roof, etc. using flat/curved panels, can solve problems such as the inability of famous farmers to be comfortable, weak thermal insulation and sound insulation performance, affecting structural strength, etc., to achieve shortened The effect of forming and curing time, shortening the cycle of forming and processing, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

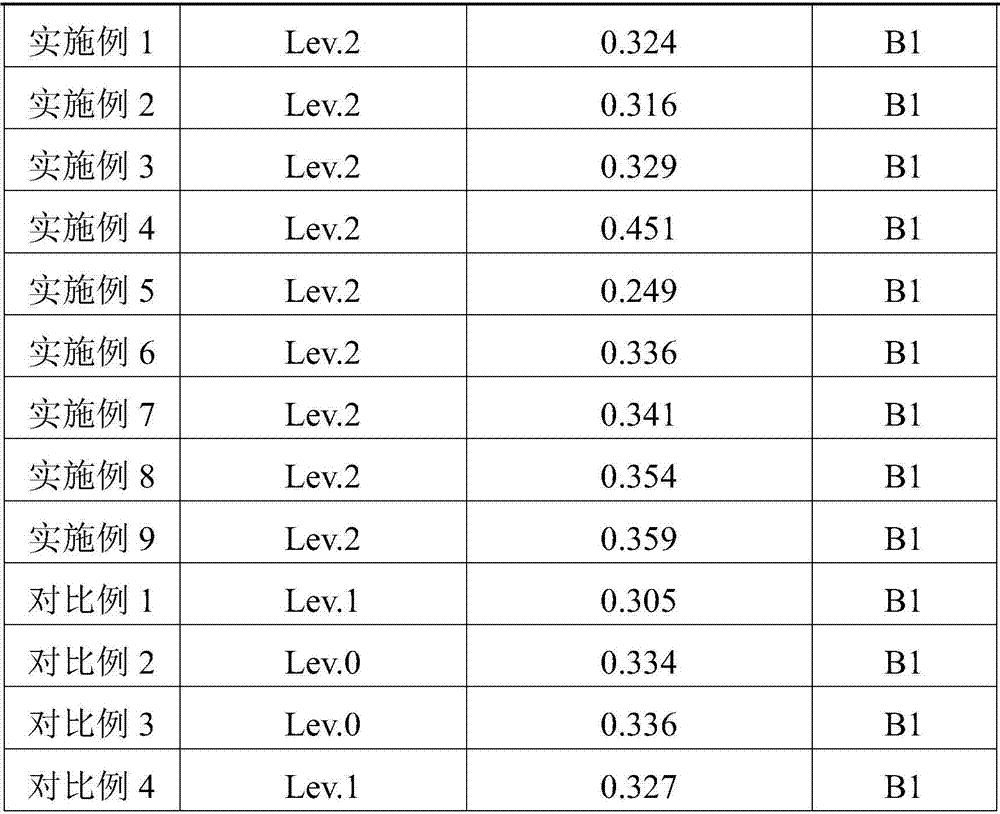

Embodiment 1

[0034] A roof cover plate for a simple house, the preparation method comprising:

[0035] (1) Asbestos fiber pretreatment

[0036] Weigh 15kg of asbestos fibers, add 9kg of water-based polyurethane emulsion (purchased from Taixing Zhongfang Auxiliary Factory, brand name PU328-9K, solid content 33%) to it, stir and mix evenly, and let stand for 2h to obtain mixture I;

[0037] (2) Weigh 40kg of cement (purchased from Anhui Chaodong Cement Co., Ltd., Dongguan brand, cement strength grade 32.5) and 100kg of yellow sand (purchased from Lingshou County Hengchuan Mineral Products Processing Plant, sand particle size distribution 10-20 order), add 350kg of water to be reconciled into cement mortar, the mixture I in the step (1) is added and stirred evenly, then add 8kg zinc oxide whiskers, continue to stir to obtain the mixture II,

[0038] (3) Spread half of the mixture II on the plastic cloth on the working table, smooth it, let it stand for 15 minutes, and then spread the carbon ...

Embodiment 2

[0041] This embodiment is the same as the preparation method of the house cover in Example 1, the difference is that the pouring amount is controlled so that the total thickness of the house cover is 8mm, wherein the thickness of the main body layer is 3.81mm, and the thickness of the carbon fiber cloth layer is 0.38mm .

Embodiment 3

[0043] This embodiment is the same as the preparation method of the house cover in Example 1. The difference is that the pouring amount is controlled so that the total thickness of the house cover is 8 mm, wherein the thickness of the main body layer is 3.72 mm, and the thickness of the carbon fiber cloth layer is 0.56 mm. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com