Ocean protist and method for fermenting and producing high-value-added lipid product

A technology of microbial strains and fermentation medium, which is applied in the field of marine protists and the use of their fermentation to produce high value-added lipid products, can solve the problems of resource exhaustion, difficulty in meeting huge demands, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

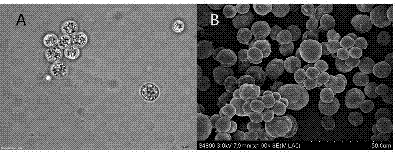

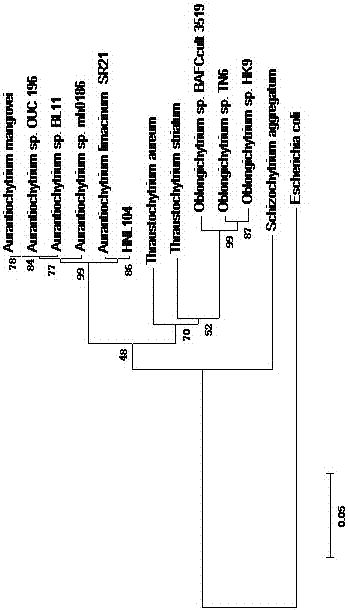

Image

Examples

Embodiment 1

[0024] Put the strains stored in glycerol tubes into a 250 ml shake flask containing 50 ml seed medium, and culture them in a shaker at 33°C at a speed of 200 rpm for 24 h to obtain first-grade seeds; Insert it into a 500 ml shake flask containing 100 ml of seed medium, and culture it in a shaker at 35°C at a speed of 200 rpm for 12 h to obtain secondary seeds; add 1.2 L of fermentation culture to a 3L bioreactor Base, access to the activated secondary seed solution. During the fermentation process, the temperature was controlled at 35°C. During the fermentation process, nitrogen supplementation was adopted, and 20% (w / v) yeast extract solution was added within 24-48 hours of fermentation. During the fermentation process, the glucose concentration in the fermentation system was maintained at 10-15 g / L by feeding 80% glucose solution. The pH was maintained at 6.5 by automatic addition of 2M NaOH or 14% citric acid. After 65 hours of fermentation, hydrogen peroxide was added ...

Embodiment 2

[0032]Put the strain stored in the glycerol tube into a 250 ml shake flask containing 50 ml of seed medium, and culture it in a shaker at 25°C at a speed of 200 rpm for 24 h to obtain first-grade seeds; Insert 100 ml of seed medium into a 500 ml shake flask, and culture in a shaker at 30°C at 200 rpm for 12 h to obtain secondary seeds; add 1.2 L of fermentation culture to a 3 L bioreactor Base, access to the activated secondary seed solution. During the fermentation process, the temperature was controlled at 33°C. During the fermentation process, the glucose concentration in the fermentation system was maintained at 10-15 g / L by feeding 80% glucose solution. Automatic addition of 2M NaOH or 14% citric acid kept the pH at 6.5. The fermentation time was 90 hours, and 10 hours before the end of the fermentation, hydrogen peroxide was added to make the concentration of hydrogen peroxide in the fermentation system 0.05%.

[0033] The fermentation medium contains: glucose 60 g / L,...

Embodiment 3

[0037] Put the strains stored in glycerol tubes into a 250 ml shake flask containing 50 ml of seed medium, and culture them in a shaker at 33°C at a speed of 200 rpm for 24 hours to obtain first-grade seeds; Put them into a 500ml shake flask with 100ml seed medium, and cultivate them in a shaker at 35°C at a speed of 200rpm for 12h to obtain secondary seeds; add 3L fermentation medium to a 5L bioreactor, and then into the activated secondary seed solution. During the fermentation process, the temperature was controlled at 37°C. During the fermentation process, the glucose concentration in the fermentation system was maintained at 10-15 g / L by feeding 80% glucose solution. The pH was maintained at 6.5 by automatic addition of 2M NaOH or 14% citric acid. The fermentation time was 90 hours, and 10 hours before the end of the fermentation, hydrogen peroxide was added to make the concentration of hydrogen peroxide in the fermentation system 0.01%.

[0038] The fermentation mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com