Wafer-level package structure and package process applied to acoustic surface wave filter

A wafer-level packaging, surface acoustic wave technology, applied in electrical components, impedance networks, etc., can solve the problems of low processing efficiency, low efficiency, increase bonding force, etc., to improve processing efficiency, improve processing efficiency, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

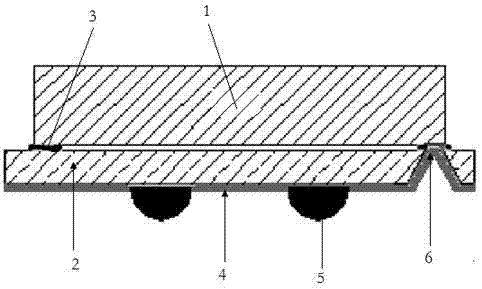

[0028] see figure 1 , it can be seen from the figure that the present invention is applied to the wafer-level packaging structure of the surface acoustic wave filter, including the filter chip substrate 1 (the commonly used material is lithium tantalate) and the packaging wafer 2, in the filter chip A circle of gold film 3 is plated on the periphery of the working surface of the substrate 1, and a circle of gold film 3 is also plated on the package wafer 2 corresponding to the gold film of each chip substrate, and the filter chip substrate 1 and the package wafer 2 pass through gold-gold bonding. An external circuit wiring structure 4 and metal solder balls 5 (usually gold balls or tin balls) for electrical connection with the PCB board are provided on the side of the packaging wafer 2 facing away from the working surface of the chip. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com