Manufacturing method of pearl plum fruit tea

A production method and pearl technology, which is applied in the field of food processing, can solve problems such as complex processes and loss of vitamin nutrients, and achieve the effects of improving taste, preventing spoilage, and preventing oxidative deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

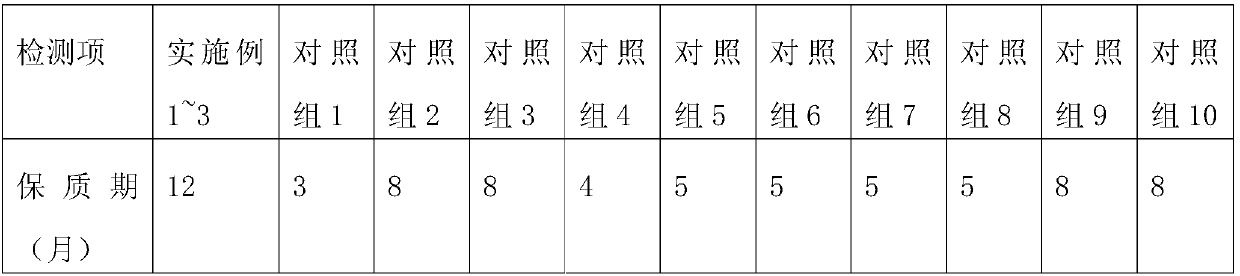

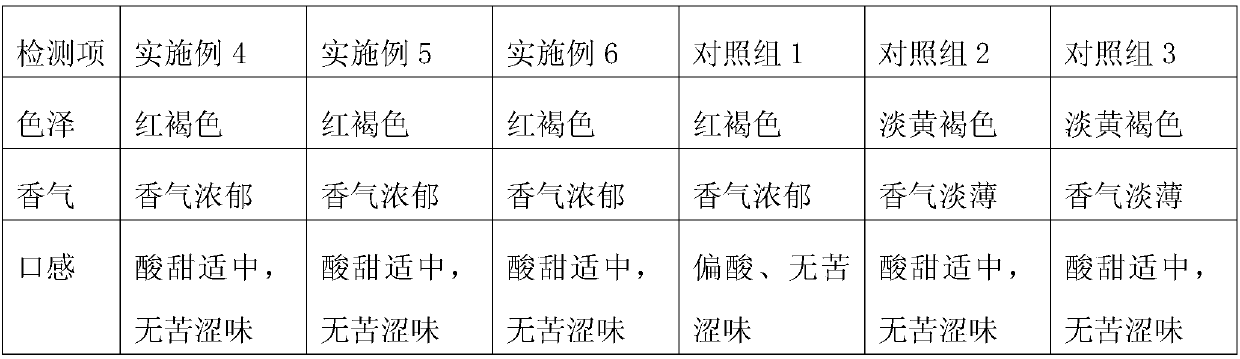

Examples

Embodiment 1

[0042] A method for making pearl plum fruit tea includes the following steps:

[0043] (1) Fruit picking, grading and washing;

[0044] (2) Enzyme-ultrasonic auxiliary treatment; leave the pearl in the enzyme solution and irradiate it with ultrasonic waves for 50 min; the conditions of the ultrasonic irradiation are: a temperature of 35°C, an ultrasonic frequency of 10kHz, and an ultrasonic power of 80W; the enzyme solution It contains the following enzymes: pectinase 2000U / mL, cellulase 3494U / mL, hemicellulase 500U / mL.

[0045] (3) Tea soup immersion; put the pearl plum fruit after enzyme-ultrasonic treatment in the tea soup, while using microwave assisted immersion for 1h; the tea soup contains 5% by mass of soluble plant polysaccharides, tea dregs and wood vinegar 5%, dragon fruit pulp 10%; the tea dregs and wood vinegar are prepared by the following method: place the tea dregs in a rotary kiln, use magnesium as a catalyst, and raise the temperature to 500°C at a rate of 10°C / min...

Embodiment 2

[0049] A method for making pearl plum fruit tea includes the following steps:

[0050] (1) Fruit picking, grading and washing;

[0051] (2) Enzyme-ultrasonic auxiliary treatment; leave the pearl in the enzyme solution and irradiate it with ultrasonic waves for 20 min; the conditions of the ultrasonic irradiation are: temperature 40°C, ultrasonic frequency 4kHz, ultrasonic power 100W; the enzyme solution It contains the following enzymes: pectinase 3843U / mL, cellulase 1000U / mL, hemicellulase 1583U / mL.

[0052] (3) Tea soup immersion; put the pearl plum fruit after enzyme-ultrasonic treatment in the tea soup, while using microwave assisted immersion for 2h; the tea soup contains 2% by mass percentage of soluble plant polysaccharides, tea dregs and wood vinegar 10%, dragon fruit pulp 1%; the tea dregs wood vinegar is prepared by the following method: the tea dregs are placed in a rotary furnace, magnesium is used as a catalyst, and the temperature is raised at a rate of 20°C / min to 400...

Embodiment 3

[0056] A method for making pearl plum fruit tea includes the following steps:

[0057] (1) Fruit picking, grading and washing;

[0058] (2) Enzyme-ultrasonic auxiliary treatment; leave the pearl in the enzyme solution and irradiate it with ultrasonic waves for 40 minutes; the conditions of the ultrasonic irradiation are: temperature 38°C, ultrasonic frequency 8kHz, ultrasonic power 90W; the enzyme solution It contains the following enzymes: pectinase 2314U / mL, cellulase 2121U / mL, hemicellulase 1212U / mL.

[0059] (3) Tea soup immersion; put the pearl plum fruit after enzyme-ultrasonic treatment in the tea soup, and at the same time use microwave assisted immersion for 2 hours; the tea soup contains 3% soluble plant polysaccharides by mass percentage, tea dregs and wood vinegar 8%, dragon fruit pulp 5%; the tea dregs wood vinegar is prepared by the following method: the tea dregs are placed in a rotary kiln, magnesium is used as a catalyst, and the temperature is raised at a rate of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com