Desoxidant with sulfur tolerance and preparation method thereof

A deoxidizer and high-performance technology, applied in the field of deoxidizer, can solve the problems of low deoxidation accuracy and oxygen capacity, inability to remove small molecule harmful gases, single function, etc., and achieve a well-developed pore structure, which is conducive to the diffusion of oxygen. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

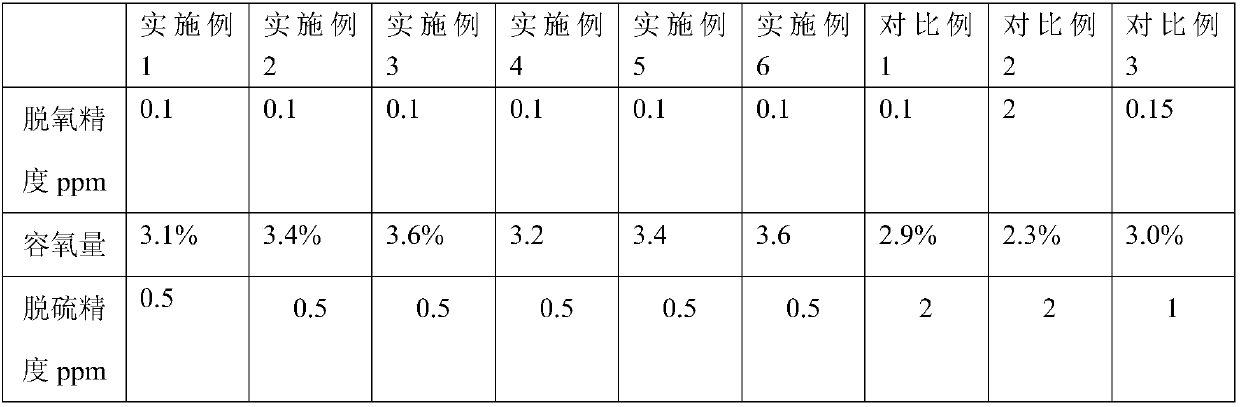

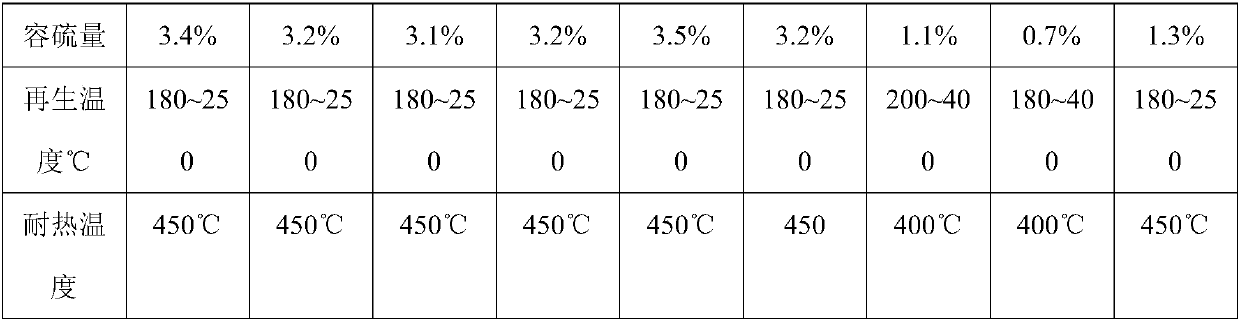

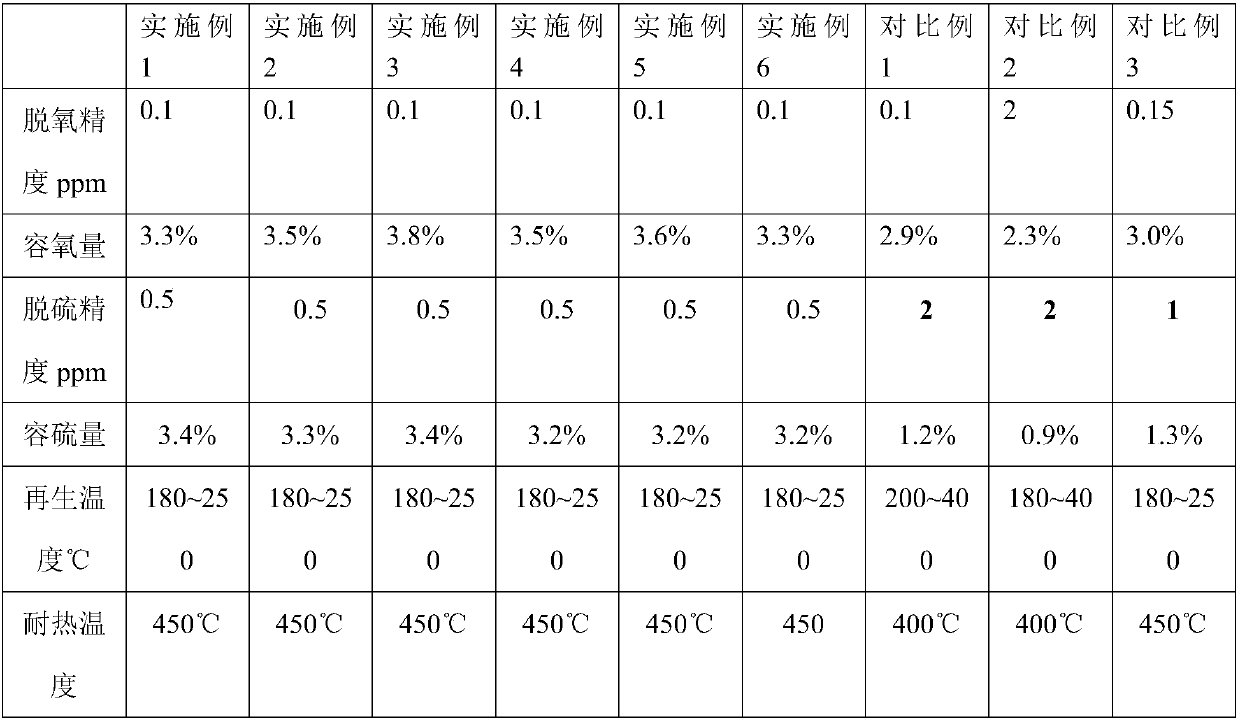

Examples

Embodiment 1

[0031] The preparation method of the deoxidizer with sulfur resistance provided by the present embodiment comprises the following steps:

[0032] (1) Preparation of modified molecular sieve: mix copper sulfate solution and zinc sulfate solution to prepare an ion exchange solution containing Cu ions and Zn ions, wherein the concentrations of Cu and Zn are 0.1mol / L and 0.03mol / L respectively; weigh Add 50 g of NaY molecular sieves to 600 g of ion exchange solution and mix, stir at a constant temperature for 20 h at a temperature of 40 ° C, filter the solution, wash 3 times, and dry at 110 ° C for 3 h to obtain a modified molecular sieve;

[0033] (2) Preparation of deoxidizer: 105g iron red, 49gMnCO 3 and 40g of modified molecular sieves were crushed to 300 mesh, mixed with 52g of kaolin, molded with water, dried in the sun, and calcined at 400°C for 4 hours to obtain a deoxidizer with sulfur resistance.

[0034] In the deoxidizer prepared by the above examples, based on the to...

Embodiment 2

[0036] The preparation method of the deoxidizer with sulfur resistance provided by the present embodiment comprises the following steps:

[0037] (1) Preparation of modified molecular sieve: Mix copper nitrate solution and zinc nitrate solution to prepare an ion exchange solution containing Cu ions and Zn ions, wherein the concentrations of Cu and Zn are 0.1mol / L and 0.03mol / L respectively; weigh 13X Add 50 g of molecular sieves to 700 g of ion exchange solution and mix, stir at a constant temperature for 20 h at a temperature of 40 ° C, filter the solution, wash 3 times, and dry at 110 ° C for 3 h to obtain a modified molecular sieve;

[0038] (2) Preparation of deoxidizer: 90g Fe(OH) 3 , 97g MnCO 3 and 40g of modified molecular sieves were crushed to 300 mesh, mixed with 50g of attapulgite, molded with water, dried in the sun, and roasted at 450°C for 4 hours to obtain a deoxidizer with sulfur resistance.

[0039] In the deoxidizer prepared by the above examples, based on th...

Embodiment 3

[0041] The preparation method of the deoxidizer with sulfur resistance provided by the present embodiment comprises the following steps:

[0042] (1) Preparation of modified molecular sieve: mix copper chloride solution and zinc chloride solution to prepare an ion exchange solution containing Cu ions and Zn ions, wherein the concentrations of Cu and Zn are 0.1mol / L and 0.03mol / L respectively; Take 50g of ZSM-5 molecular sieve, add it to 700g of ion exchange solution and mix, stir at a constant temperature for 20h at a temperature of 40°C, filter the solution, wash 3 times, and dry at 110°C for 3h to obtain a modified molecular sieve;

[0043] (2) Deoxidizer preparation: 190g Fe 3 o 4 , 72gMnO 2 and 45g of modified molecular sieves were crushed to 300 mesh, mixed with 43g of diatomaceous earth, formed by adding water, dried naturally, and calcined at 450°C for 4 hours to obtain a deoxidizer with sulfur resistance.

[0044] In the deoxidizer prepared by the above examples, ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com