Rare earth enhanced magnesium-zinc alloy seamless pipe hot extrusion technology and temperature control extrusion die

A seamless pipe and hot extrusion technology, applied in metal extrusion dies, metal extrusion, manufacturing tools, etc., can solve the problems of poor pipe accuracy and poor pipe quality, and achieve good processing quality, high quality rate, and extrusion. The effect of low compressive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

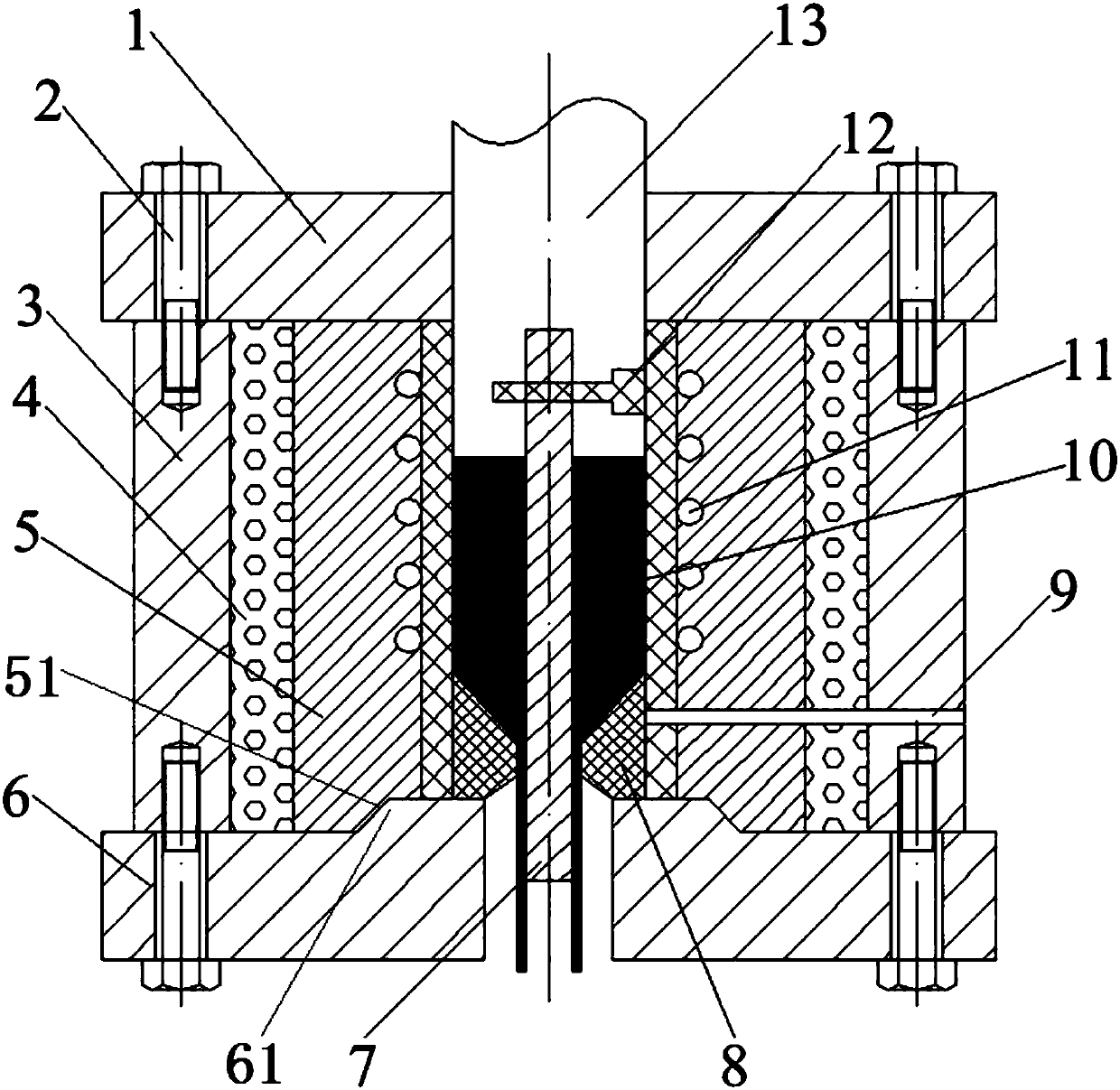

[0052] Embodiment: This embodiment is a hot-extruded Mg-2.0Zn-0.6Y-0.4Nd magnesium alloy seamless pipe with an outer diameter of 7 mm and an inner diameter of 4 mm.

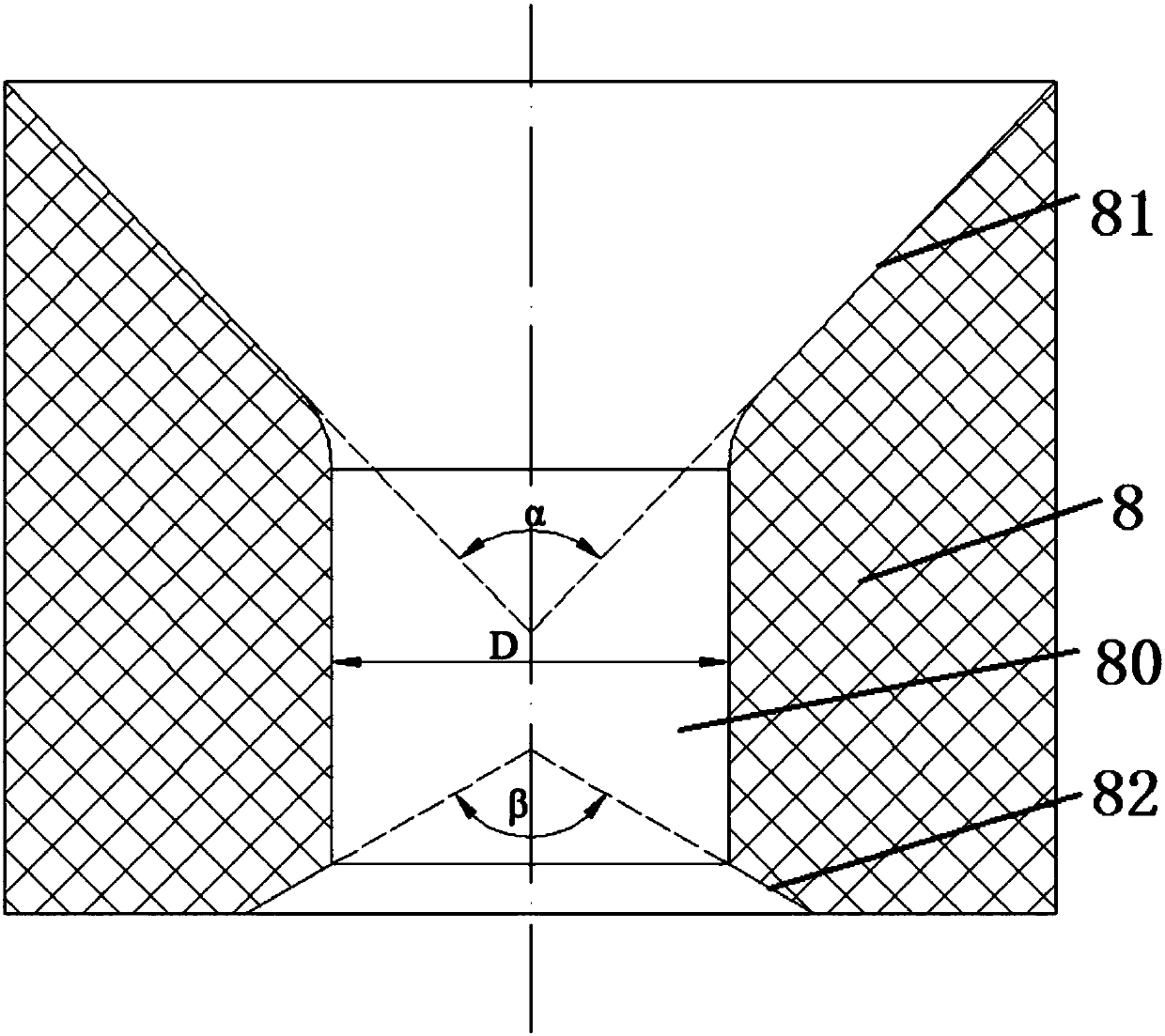

[0053] The temperature control extrusion mold used in this embodiment refers to figure 1 . The inner extruding cylinder 10 and the outer extruding cylinder 5 are limited and fixed through taper cooperation. There are spirally arranged heating wires 11 inside the outer extruding cylinder 5. There are temperature measuring holes on the lower side of the inner and outer extruding cylinders 10. The thermocouple 9 in the temperature measuring hole and the heating wire 11 form an automatic temperature control system through an external temperature control device; the inner diameter of the inner extrusion cylinder 10 is 30mm, and the outer mold 8 of the pipe is in direct contact with the inner wall of the inner extrusion cylinder 10 through transition fit, and the extruded The indenter 7 has a diameter of 4mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com