Breathing type pressure-assisted shallow freezing and unfreezing integrated equipment and application method thereof

A pressure and equipment technology, applied in the field of thawing integrated equipment and breathing pressure-assisted shallow freezing, can solve the problems of rapid deterioration of quality, short storage time, loss of protein nutrients, etc., to shorten the pre-cooling time and reduce the volume of ice crystals , the effect of small loss of tissue fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 (shallow freezing at -9°C)

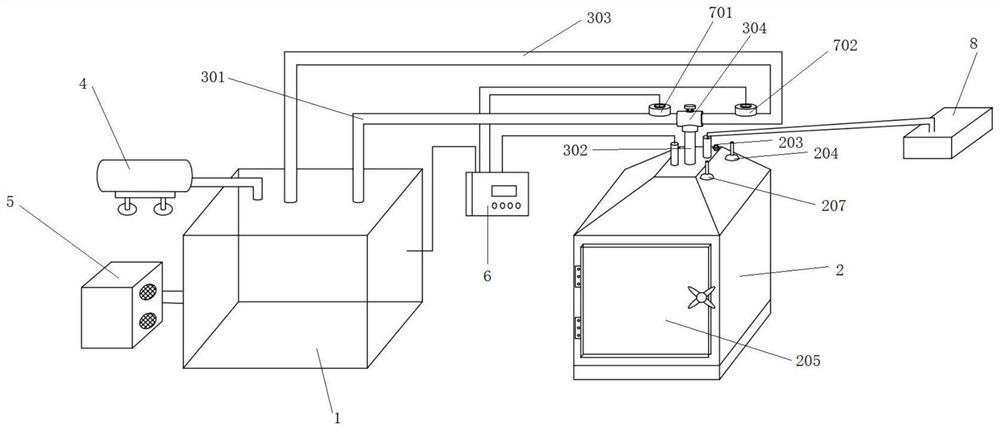

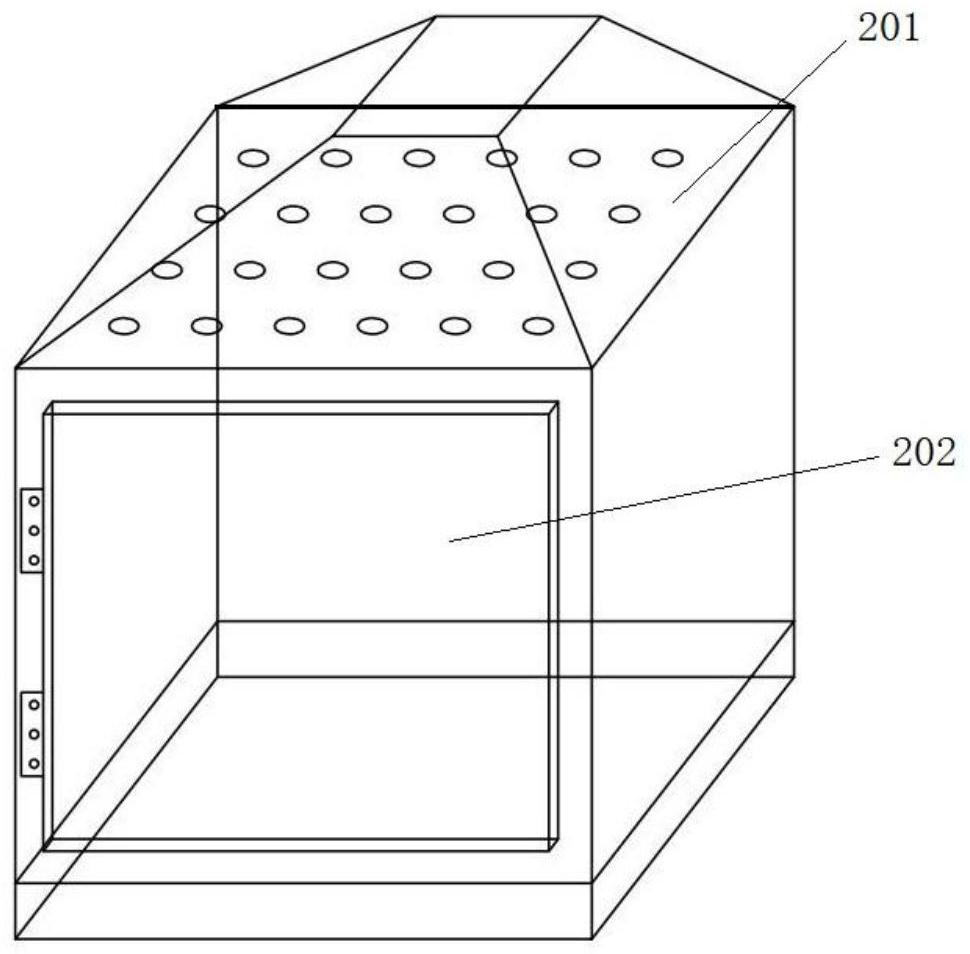

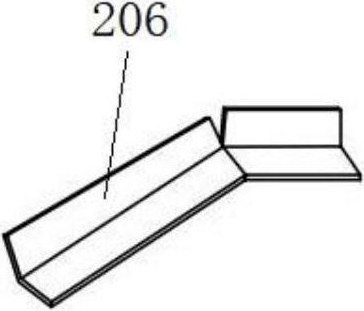

[0040] Such as Figure 1-3As shown, a breathable pressure-assisted shallow freezing and thawing integrated equipment includes a cold air temporary storage room 1, a storage room / thawing room 2, an air duct 3, an air compressor 4, a compressor 5, a controller 6, and a solenoid valve 7 and humidifier 8; the cold air temporary storage room 1 communicates with the outlet pipes of the air compressor 4 and compressor 5 respectively, is electrically connected with the controller 6, and communicates with the storage room / thawing room 2 through the air duct 3; the storage room The / thawing chamber 2 is connected with a humidifier 8; the controller 6 is electrically connected to the solenoid valve 7 and the storage room / thawing chamber 2, and the controller 6 controls the pressure, temperature and time of the cold air in the material chamber. The air duct 3 is provided with a solenoid valve 7 . The storage room / thawing room 2 includes a col...

Embodiment 2

[0049] Example 2 (shallow freezing at -10°C)

[0050] Used equipment is identical with embodiment 1;

[0051] The application method of the above-mentioned breathing pressure-assisted shallow freezing and thawing integrated equipment in the shallow freezing, preservation and thawing of chilled fresh meat includes the following steps:

[0052] Step 1. After the fresh mutton is divided, carry out necessary trimming;

[0053] Step 2, immediately put the trimmed fresh mutton into the drawable tray, then put it into the material rack, the material rack enters the material chamber 202 along the foldable track 206, close the feeding door 205, and keep it in a sealed state;

[0054] Step 3: Turn on the compressor 5, open the first solenoid valve 701 through the controller 6, close the second solenoid valve 702, and transmit the cold air at a temperature of -14°C from the cold air temporary storage room 1 to the storage room / thawing room through the air duct 3 / 2, fast pre-cooling of...

Embodiment 3

[0059] Example 3 (shallow freezing at -12°C)

[0060] Used equipment is identical with embodiment 1;

[0061] The application method of the above-mentioned breathing pressure-assisted shallow freezing and thawing integrated equipment in the shallow freezing, preservation and thawing of chilled fresh meat includes the following steps:

[0062] Step 1. After the fresh mutton is divided, carry out necessary trimming;

[0063] Step 2, immediately put the trimmed fresh mutton into the drawable tray, then put it into the material rack, the material rack enters the material chamber 202 along the foldable track 206, close the feeding door 205, and keep it in a sealed state;

[0064] Step 3: Turn on the compressor 5, open the first electromagnetic valve 701 through the controller 6, close the second electromagnetic valve 702, and transmit the cold air at a temperature of -15°C from the cold air temporary storage room 1 to the storage room (thawing room) through the air duct 3 ) 2. Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com