Preparation method of high quality and high molecular weight carboxymethyl chitosan

A carboxymethyl chitosan and high molecular weight technology is applied in the field of preparation of carboxymethyl chitosan, can solve the problems of difficult isoelectric point control of carboxymethyl chitosan, etc., and achieves long action time and high quality. Good, heat-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

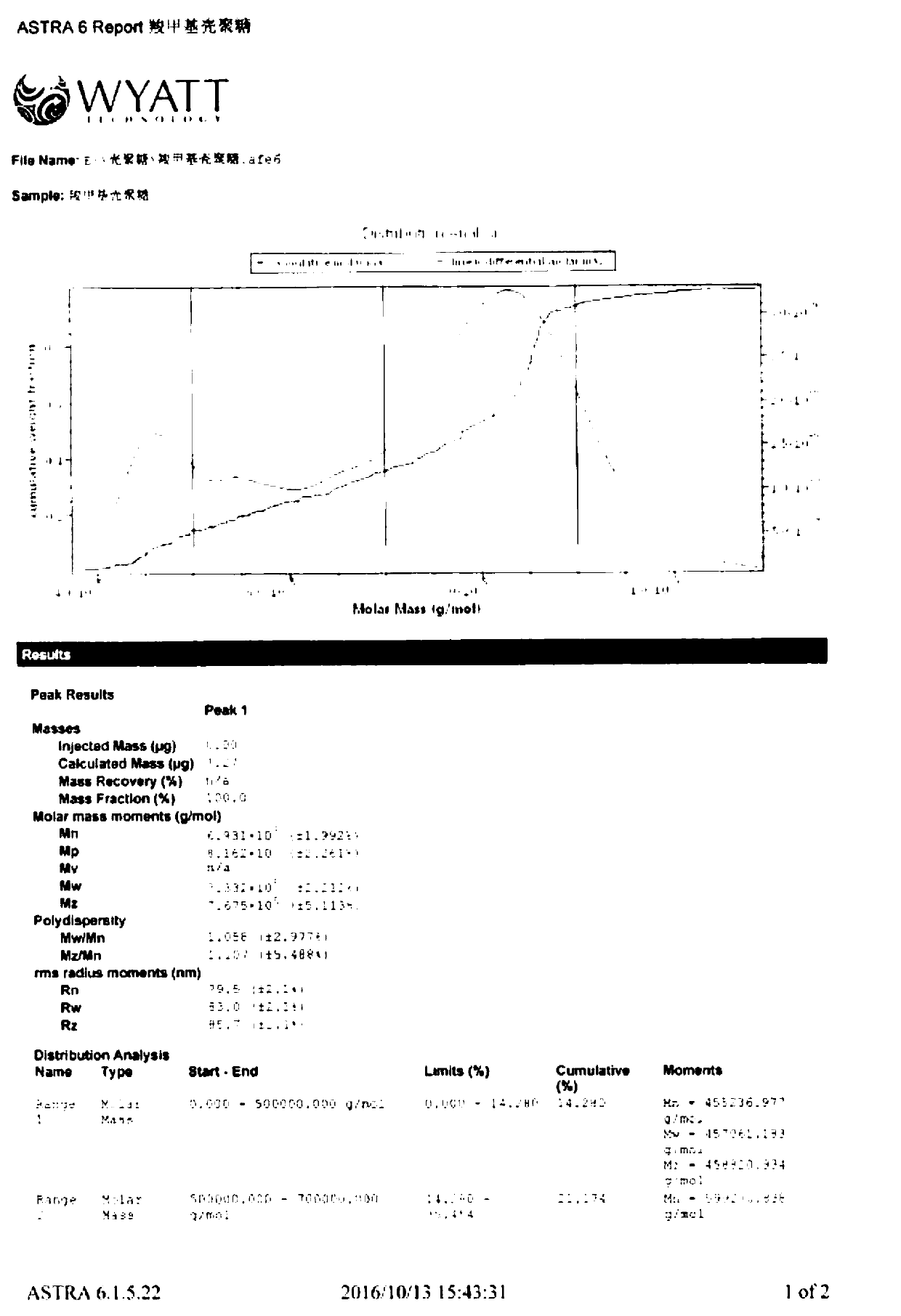

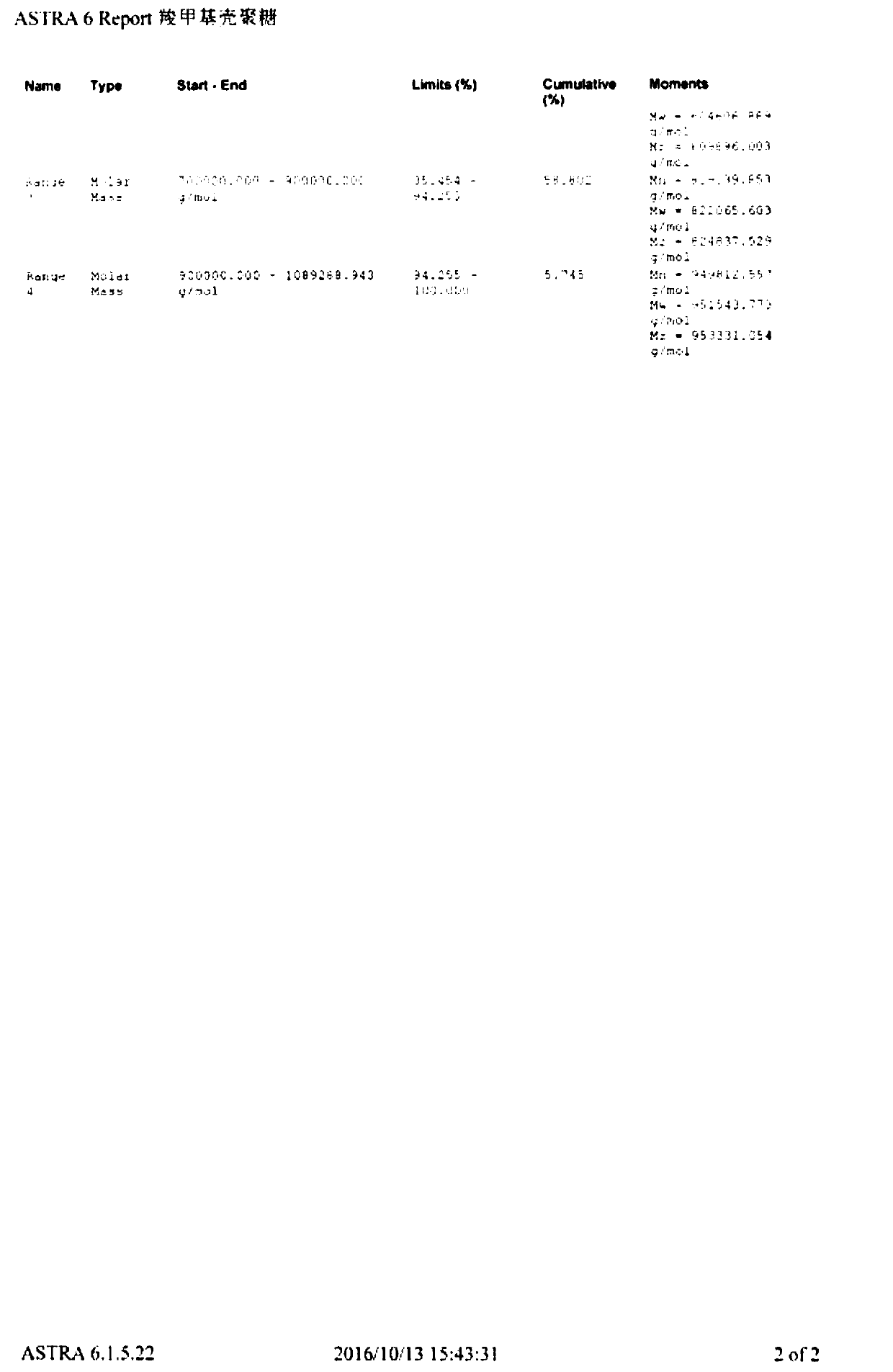

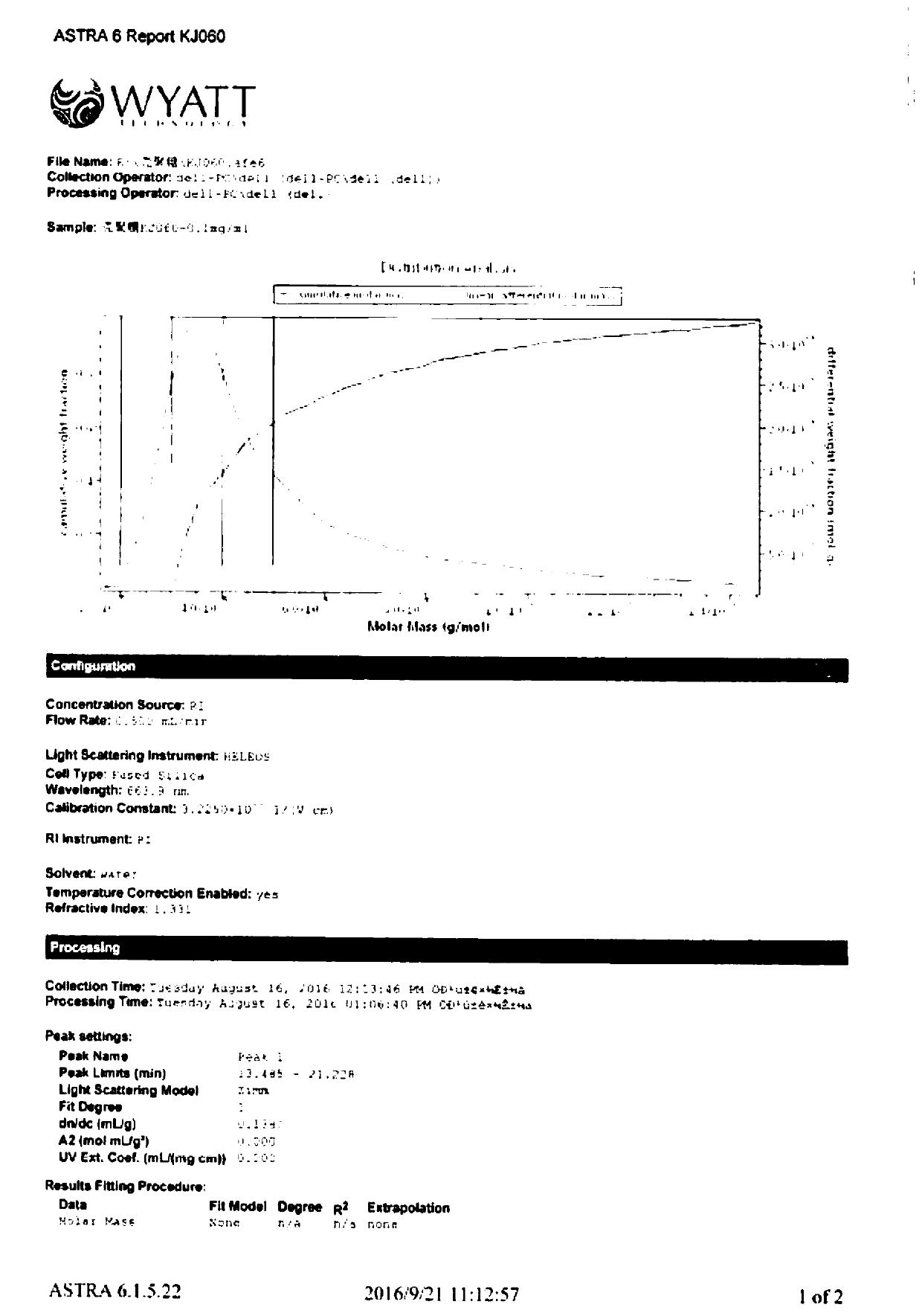

Image

Examples

Embodiment 1)

[0026] The preparation method of the high-quality high molecular weight carboxymethyl chitosan of the present embodiment comprises the following steps:

[0027] ① Preparation of crude carboxymethyl chitosan.

[0028] Add sodium hydroxide in isopropanol solution in the reaction flask, the concentration of sodium hydroxide is 40%.

[0029] Add chitosan with a deacetylation degree of 15% to 45% into the reaction flask, and the mass ratio of chitosan to sodium hydroxide after adding is 1:4.8.

[0030] Slowly add the pre-dissolved isopropanone solution of chloroacetic acid dropwise into the reaction flask under stirring, and continue to stir and react for 3 hours after the addition. The mass ratio of chitosan to chloroacetic acid is 5:1.

[0031] After the reaction is completed, add concentrated hydrochloric acid to the reacted material, adjust the pH value of the material to 6-7, filter with suction, wash the filter cake 3 times with absolute ethanol, and dry the washed filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com