A kind of bipolar plate for vanadium battery and preparation method thereof

A bipolar plate and vanadium battery technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of large body resistance, low mechanical strength, poor battery performance, etc., achieve good conductivity, balance mechanical strength, improve Effect of Mechanical Strength and Corrosion Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

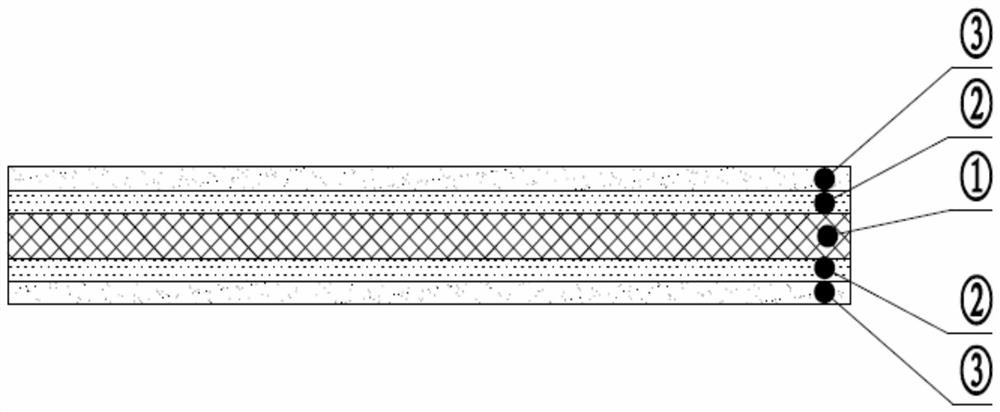

[0025] Place a 0.3mm thick carbon cloth in an incubator, control the temperature at 200°C, put polypropylene powder with a particle size of 0.04mm into the spray gun, and spray it on both sides of the carbon cloth with a coating thickness of 0.5mm, and then Graphite powder with a particle size of 0.02mm is sprayed on the surfaces of both sides of the resin layer, the coating thickness is 0.05mm, and then it is put into a mold and hot-pressed on a hot press to make a bipolar plate for a vanadium battery. The hot-pressing temperature is 175°C, the hot pressing time is 55min, and the hot pressing pressure is 18MPa.

[0026] The bipolar plates prepared in this example assemble 2KW vanadium batteries, and the battery charge and discharge performance parameters are: Coulombic efficiency 95.2%, voltage efficiency 85.8%, energy efficiency 81.7%, compared with the existing carbon-plastic bipolar plates, the voltage efficiency has improved 4.3%.

Embodiment 2

[0028] Place a 0.8mm thick carbon cloth in an incubator, control the temperature at 250°C, put polypropylene powder with a particle size of 0.05mm into the spray gun, and spray it on both sides of the carbon cloth with a coating thickness of 1.0mm. Spray carbon black powder with a particle size of 0.02mm on the surface of both sides of the resin layer, the coating thickness is 0.1mm, and then put it into the mold and press it on a hot press to make a bipolar plate for a vanadium battery. The temperature is 185°C, the hot pressing time is 25min, and the hot pressing pressure is 25MPa.

[0029] The bipolar plates prepared in this example assemble a 2KW vanadium battery, and the battery charge and discharge performance parameters are: Coulombic efficiency 96.5%, voltage efficiency 86.5%, and energy efficiency 83.5%. Compared with the existing carbon-plastic bipolar plates, the voltage efficiency has improved 5%.

Embodiment 3

[0031] Place a 0.5mm thick carbon cloth in an incubator, control the temperature at 210°C, put polyethylene powder with a particle size of 0.06mm into the spray gun, and spray it on both sides of the carbon cloth with a coating thickness of 0.5mm, and then Spray carbon fiber powder with a particle size of 0.10mm on the surface of both sides of the resin layer, the coating thickness is 0.13mm, and then put it into the mold and press it on a hot press to make a bipolar plate for a vanadium battery. The hot pressing temperature is 155°C, the hot pressing time is 35min, and the hot pressing pressure is 20MPa.

[0032] The bipolar plates prepared in this example assemble a 2KW vanadium battery, and the battery charge and discharge performance parameters are: Coulombic efficiency 95.9%, voltage efficiency 86.0%, and energy efficiency 82.5%. Compared with the existing carbon-plastic bipolar plates, the voltage efficiency has improved 4.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com