Instant edible mushrooms and processing method thereof

A processing method and technology of edible fungi, applied in food science, heating and preservation of fruits/vegetables, etc., can solve the problems of perishable fungi, reduced commodity value, time-consuming cooking, etc., and achieve high nutrient retention rate and short production cycle , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

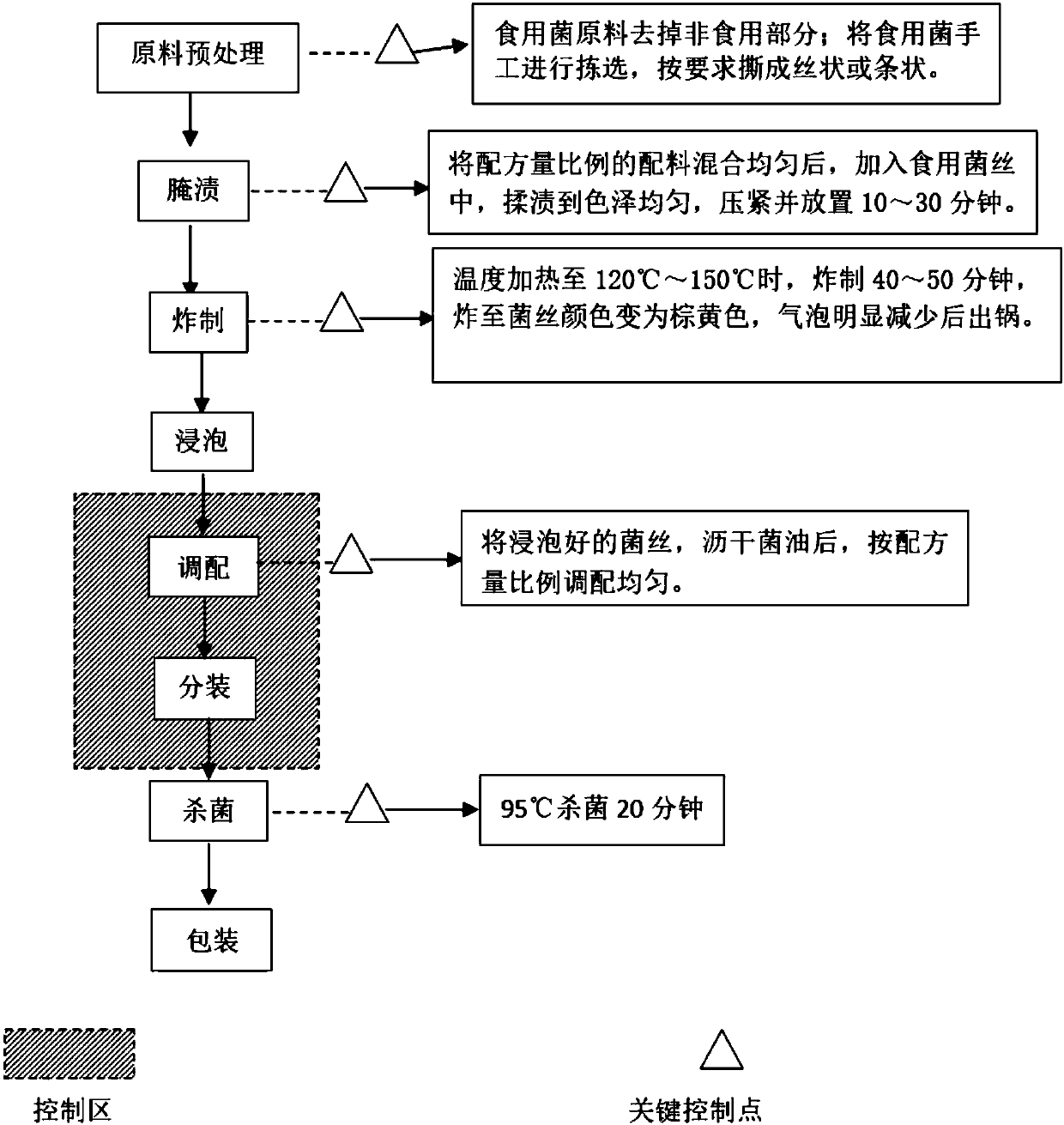

Method used

Image

Examples

Embodiment 1

[0025] A processing method of fragrance-type ready-to-eat edible fungus, comprising the steps of:

[0026] S1. Sorting: Manually sort the Coprinus chanterelles, and remove the old mushroom heads, moldy fungi or physical impurities at the roots;

[0027] S2. Silk making: Tear the selected coprinus mushrooms into filaments or strips; when processing, the maximum diameter of the stem is ≤1cm, and when the diameter of the whole tree is 0.3-1cm, it must be broken into two parts; the arc length of the cap fan ≤3cm, mycelium length shall not exceed 8cm;

[0028] S3. Pickling: put the mycelia of Coprinus coprinus in a pickling barrel, take ginger residue or dried ginger powder with 0.24% of the mycelium of Coprinus coprinus and boil it with 15 times the amount of water for 20-40 minutes, and then use 300 mesh Filter through a filter cloth and collect ginger juice for later use; take 0.5% white sugar, 3.0% soy sauce, 0.22% salt and ginger juice of Coprinus coprinus mycelium mass and m...

Embodiment 2

[0035] A processing method of spicy type instant edible fungus, comprising the steps of:

[0036] S1. Sorting: Manually sort tea tree mushrooms to remove old fungus heads, moldy fungus or physical impurities at the roots;

[0037] S2. Silk making: Tear the selected tea tree mushrooms into filaments or strips; when processing, the maximum diameter of the fungus stem is ≤1cm, and when the diameter of the whole tree is 0.3-1cm, it must be broken into two parts; the arc length of the cap fan ≤ 3cm, mycelium length shall not exceed 8cm;

[0038] S3. Pickling: put the tea tree mushroom mycelium in a pickling barrel, take ginger residue or dried ginger powder with 0.24% of the tea tree mushroom mycelium quality, boil it with 15 times the amount of water for 20-40 minutes, and then use a 300-mesh filter cloth Filter and collect the ginger juice for later use; take 0.5% white sugar, 3.0% soy sauce, 0.22% salt and ginger juice by the quality of the mycelium of tea tree mushroom, mix th...

Embodiment 3

[0045] A processing method for fresh-flavored instant edible mushrooms, comprising the steps of:

[0046] S1. Sorting: remove the edible fungus whose roots, rotten or damaged parts are removed, and wash with water to remove the cultivation substrate and impurities on the surface;

[0047] S2. Silk making: Tear the edible mushrooms treated in step S1 into filaments or strips; the maximum diameter of the dried mushrooms is ≤1cm, and when the diameter of the whole tree is 0.3-1cm, it must be broken into two parts; the arc length of the mushroom cap is ≤ 3cm, mycelium length shall not exceed 8cm;

[0048] S3. Pickling: put the mycelium in a suitable pickling barrel, mix 1.5% of the mycelium with edible salt and 6.0% of production water to dissolve it, add it to the mycelium, add 15% soy sauce, and knead until the color is uniform , marinate for 10-30 minutes;

[0049] S4, brine preparation: take 0.12% star anise, 0.20% Luo Han Guo broken, 2.3% ginger, 0.15% cinnamon, wrap them i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com