Formula of 3D-printing artificial bone composite fiber protein scaffold and preparation method of same

A protein scaffold and composite fiber technology, applied in the field of medicine, can solve the problems of immune rejection, spread of diseases, bleeding in the bone harvesting area, etc., and achieve the effect of promoting bone regeneration, good bone conduction and osteoinduction, and inducing osteogenic differentiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

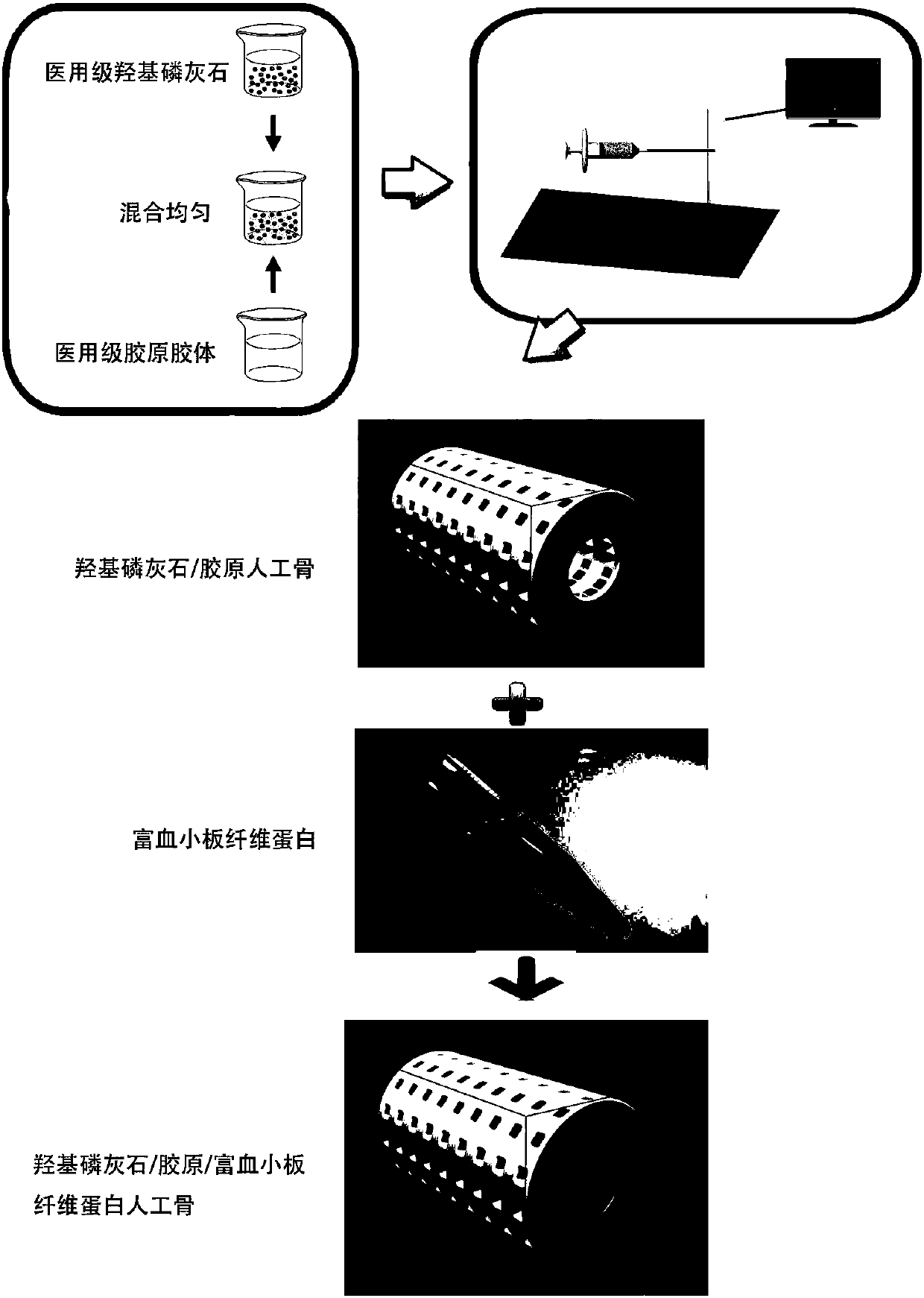

[0024] The formula of 3D printing artificial bone listed in this example is made of the following raw materials: medical grade collagen powder, 0.05mol / L acetic acid solution, medical grade hydroxyapatite powder, and 1% genipin solution by mass fraction.

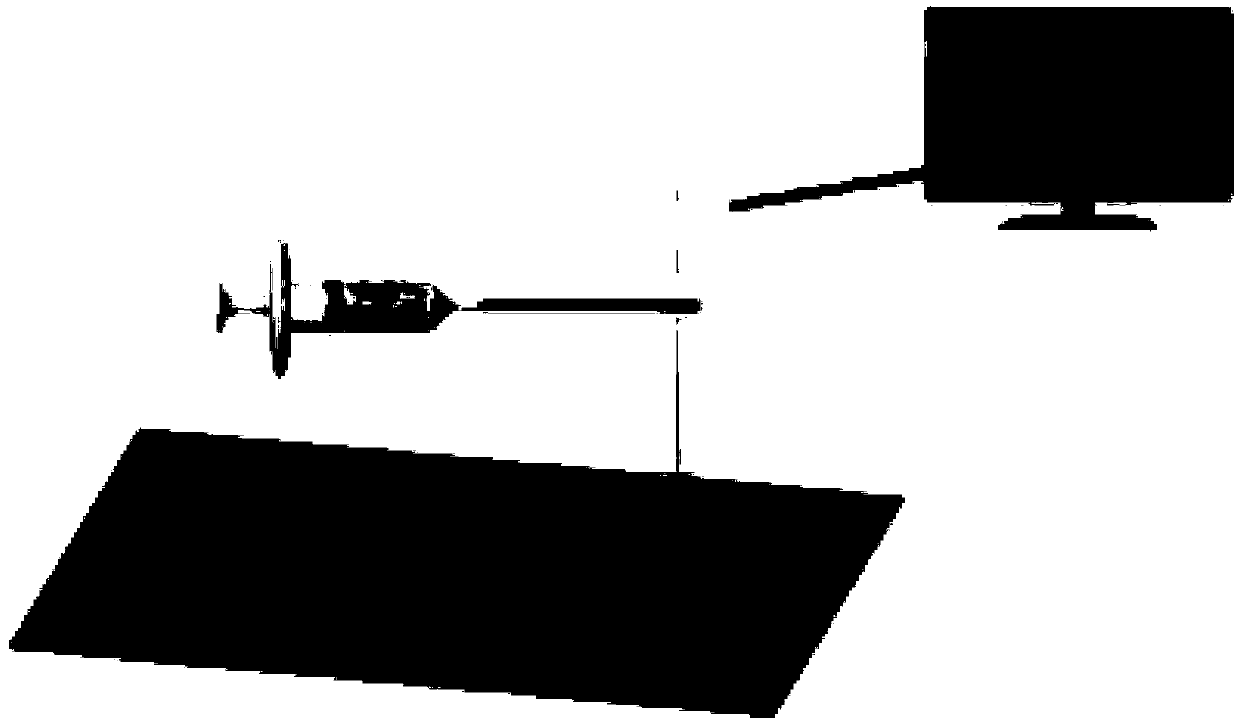

[0025] The formula and preparation method thereof of 3D printing artificial bone composite fibrin scaffold according to claim 1, is characterized in that: carry out according to the following steps:

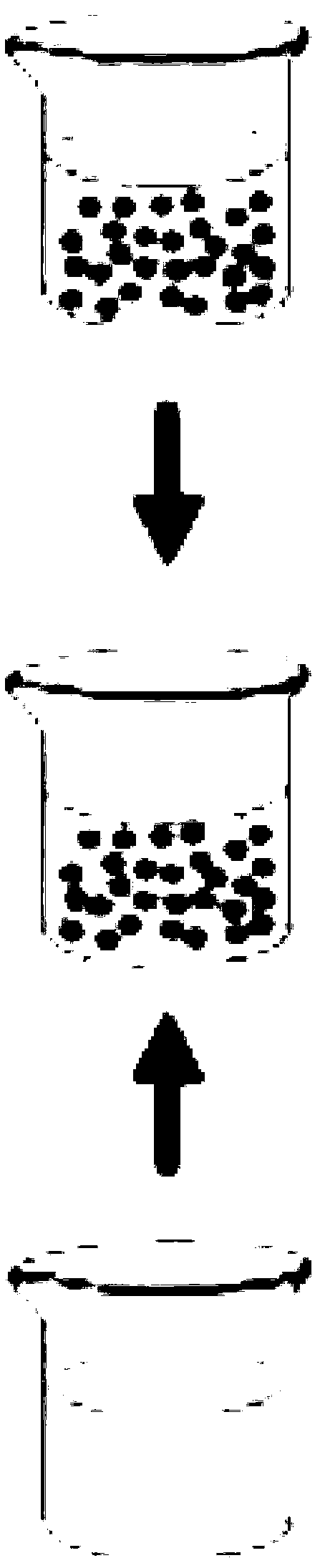

[0026] (1), preparation of collagen colloid: 5g of medical grade collagen powder is dissolved in 0.05mol / L acetic acid solution of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com