A porous metal bone implant material and its preparation method and application

A technology of bone implant material and porous metal, which is applied in the field of porous metal bone implant material and its preparation, can solve the problems of difficulty in growing bone tissue, and the pores of porous materials should not be too small, so as to improve biological inertness and maintain natural raw materials. Has attributes and promotes good integration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the porous metal bone implant material disclosed by the present invention comprises the following steps:

[0039] Step 1: Prepare individualized and customized 3D printed metal implant materials. Collect the patient's CT image data, analyze and design the individualized implant material shape and internal pore structure for the patient in the 3D image software. Wherein, the rod width is 100-800 μm, the pore diameter is 100-1000 μm, and the image is filled and expanded with cube or regular dodecahedral structural units to obtain a three-dimensional image of the target implant. The three-dimensional image file is imported into a metal material 3D printer to prepare a porous metal implant whose shape and pore structure are consistent with the design graphics. Implant materials were ultrasonically cleaned in alcohol, acetone, and distilled water for 20 minutes each to remove surface dirt, and dried in an oven at 50-60°C or air-dried for later use....

Embodiment 1

[0045] Example 1 Preparation of a porous metal bone implant material for people with diabetes

[0046] 1. Prepare individualized and customized 3D printing metal implant materials.

[0047] (1) For diabetic patients, collect the CT image data of the patient's bone defect, import it into the three-dimensional image software CAD, and design the shape and internal pore structure of the individualized target implant material according to the specific conditions of the patient. Among them, the width of the rod is 200 μm, and the average pore diameter is 400 μm. The image is filled and expanded with cube structural units to obtain a three-dimensional image of the target implant.

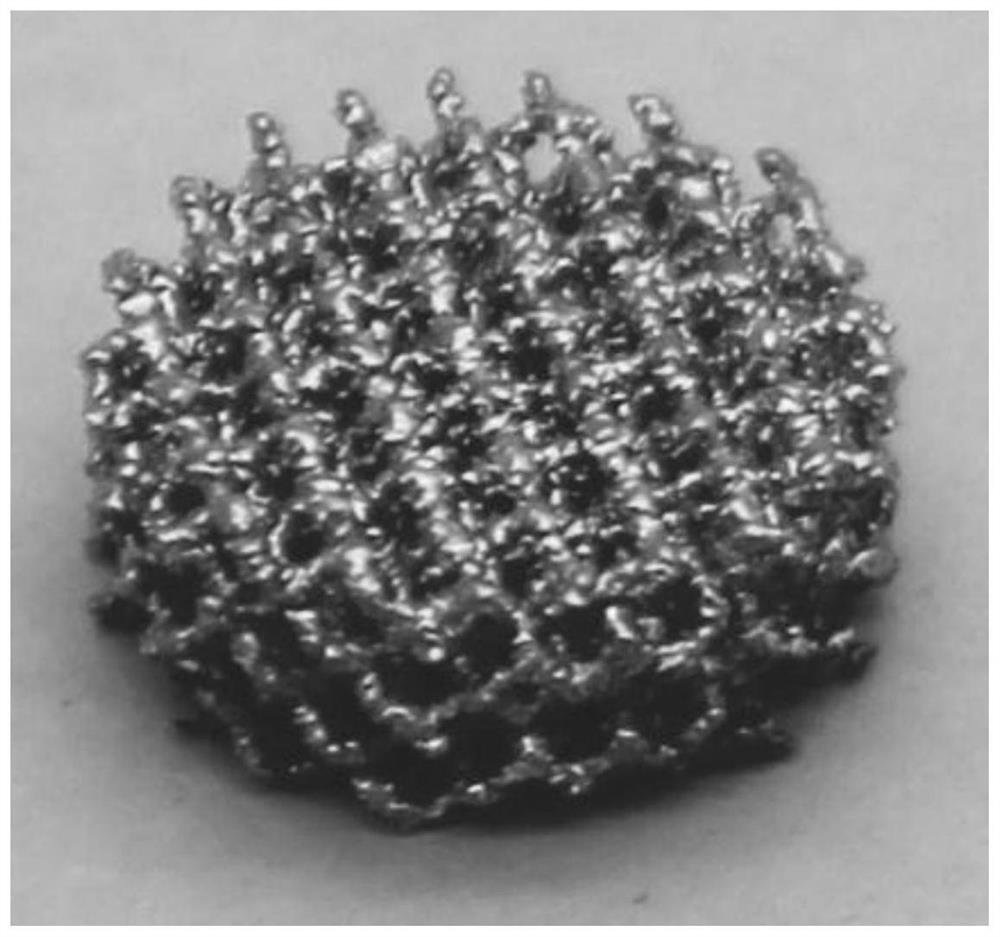

[0048] (2) Import the three-dimensional image file into the electron beam melting (EBM) metal material 3D printer, and use Ti with a diameter of 30 μm 6 Al 4 V alloy powder, through 3D printing to prepare individualized porous metal implants, see figure 1 .

[0049] (3) The porous metal implant materia...

Embodiment 2

[0058] Example 2 Preparation of a porous metal bone implant material for people with diabetes

[0059] This embodiment is partly the same as the embodiment, the difference is:

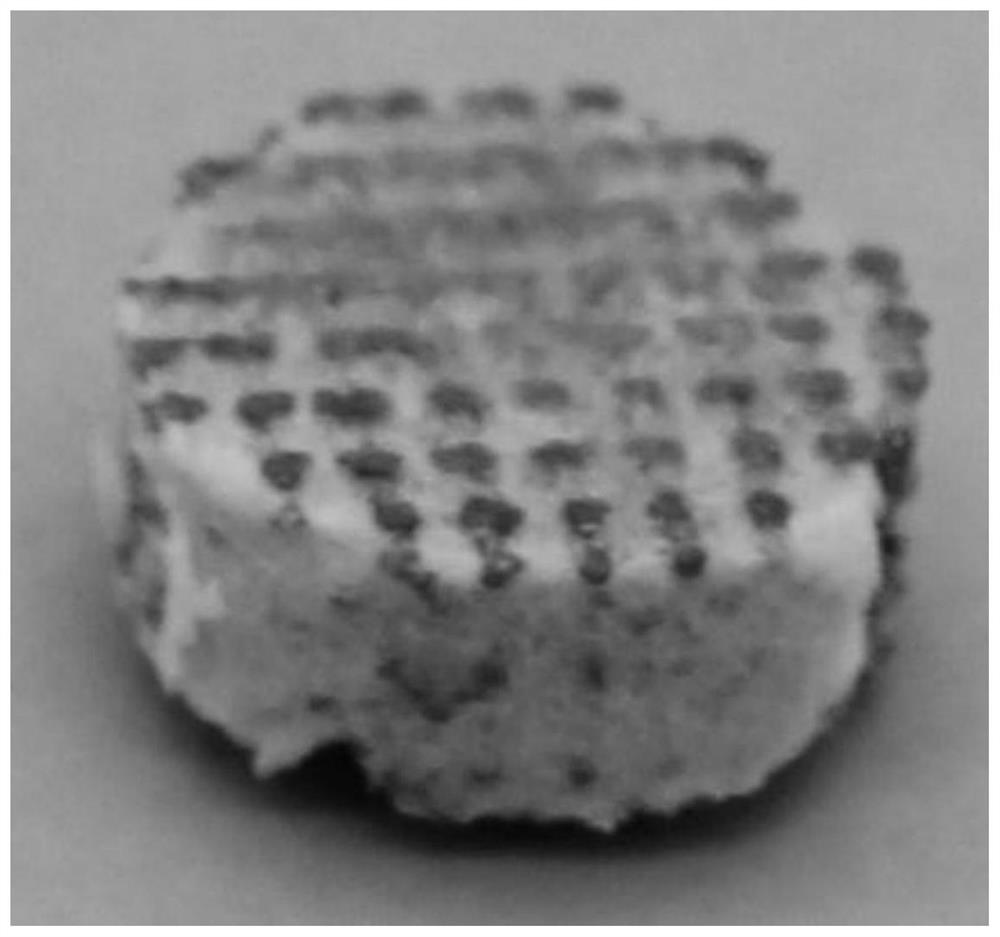

[0060] 1. In the first step, the width of the porous metal rod designed in the CAD software is 400 μm, the average pore diameter is 800 μm, and the pores of the material are filled with regular dodecahedral structural units. Using chromium-cobalt-molybdenum alloy microspherical material powder with a diameter of 20 μm, electron beam fusion 3D prints a porous metal material matrix.

[0061] 2. In the second step, the ratio of the dry weight of silk fibroin to the total volume of pores inside the material is 0.1g: 1cm 3 The proportion of silk fibroin is weighed, dissolved to prepare a silk fibroin solution, and set aside.

[0062] 3. In the third step, weigh the agonist AdipoRon of the adiponectin receptor, wherein the mass ratio of AdipoRon to silk fibroin is 1:1×10 4 . Add AdipoRon to the silk fibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com