Maps modified silica filled pim-1 composite film and preparation method thereof

A PIM-1, silica technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, membranes, etc., can solve the problems of high cost of carbon nanotubes and limited improvement of separation efficiency, and improve pervaporation performance. , high separation ability, the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a MAPS-modified silica-filled PIM-1 composite membrane provided in an embodiment of the present invention comprises the following steps:

[0026] S1, PIM-1 preparation: 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobiindole, Nitrile, catalyst and the first solvent are mixed, heated and stirred at 140-165°C for 30-60 minutes under the condition of inert gas, and the crude product is obtained, and the crude product is dissolved in the second solvent, stirred for 5-15 minutes, filtered, washed and dried Obtain PIM-1, wherein, catalyst comprises K 2 CO 3 .

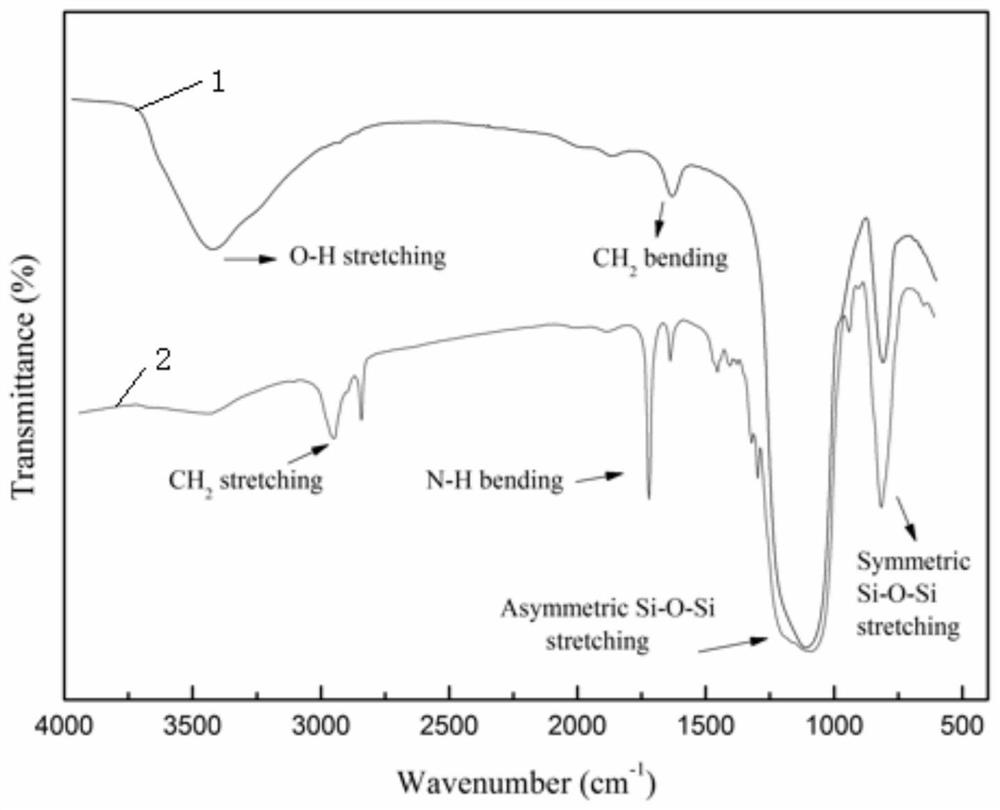

[0027] S2, Preparation of modified silica: Disperse nano fumed silica and γ-(methacryloyloxy)propyltrimethoxysilane in the third solvent, stir magnetically for 50-80 minutes, and then ultrasonically treat for 20-40 minutes , to obtain a modified silica solution.

[0028] S3, pour the modified silicon dioxide solution into the PIM-1 solution with a mass fraction of 8-12%, and mix to ob...

Embodiment 1

[0043] A kind of MAPS modified silica filled PIM-1 composite membrane provided in this embodiment is prepared according to the following method:

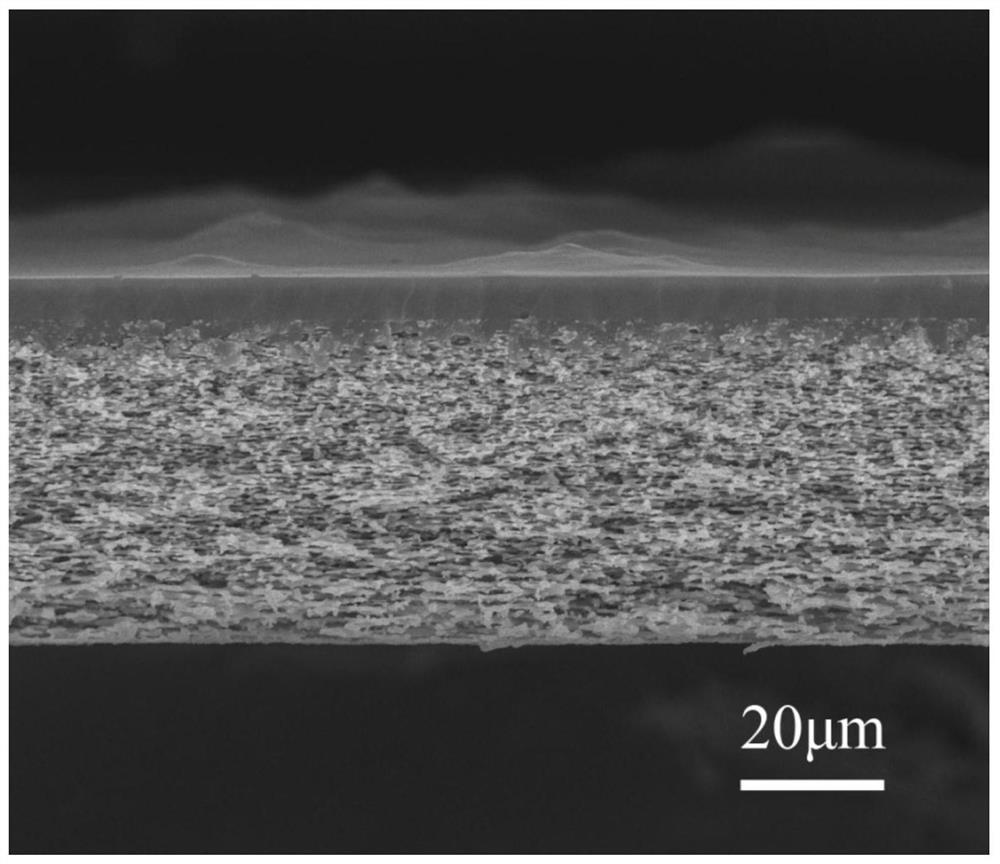

[0044] (1) Pretreatment of the support layer: place the CA microfiltration membrane in deionized water for 2 hours before use.

[0045] (2) Preparation of PIM-1: 8.3g K 2 CO 3 , 6.8g 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobiindole, 4g tetrafluoroterephthalonitrile, 15mL Add toluene and 30mL of N,N-dimethylacetamide into a 500mL three-necked flask. Heat and stir at 155°C, and stir with nitrogen gas. The crude product was collected after 40 min. The crude product was dissolved in a chloroform / methanol mixture, stirred for 10 min, and the precipitate was obtained by filtration, and the solvent and salt in the precipitated product were washed away with deionized water. Then the product was placed in a vacuum oven at 100° C. for 12 hours to obtain the final product of PIM-1.

[0046] (3) Preparation of PIM-1 solutio...

Embodiment 2

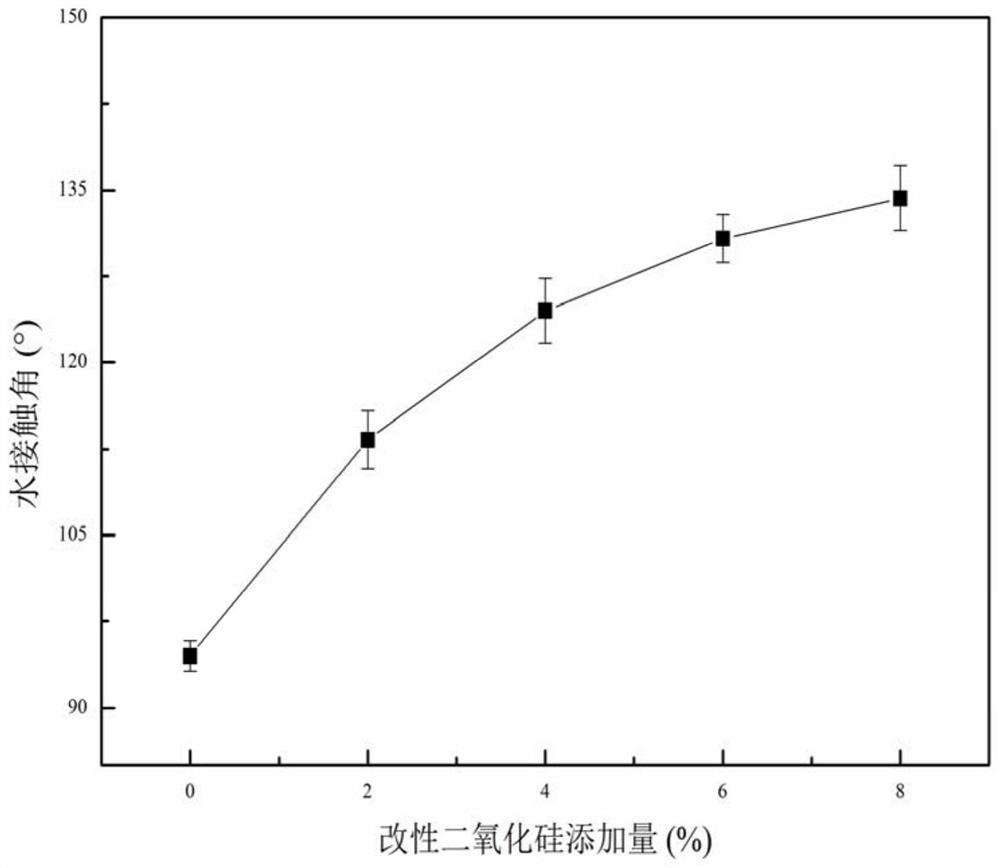

[0053] The PIM-1 composite membrane filled with MAPS modified silica provided in this example is different from Example 1 in that the amount of modified silica added is 4%.

[0054] The PIM-1 composite membrane that present embodiment makes measures pervaporation performance at 40 ℃ of 5% n-butanol aqueous solution, and its permeation flux is 509g m -2 h -1 , the separation factor is 15.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com