Method for extracting cinnamomum camphora essential oil enriched with 1,8-cineole by using ionic liquid as green medium

A technology for ionic liquid and linalool essential oil, which is applied in the directions of essential oils/spice, fat production, organic chemistry, etc., can solve the problems of poor designability of ionic liquids, and achieves high economic and social benefits, simple preparation method and good quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

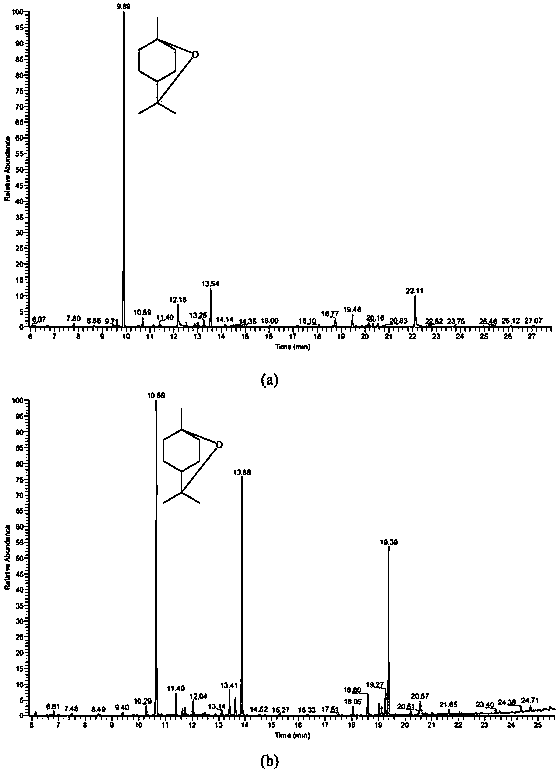

[0026] Fresh Cinnamomum camphora leaves are crushed with a pulverizer and passed through a 20-mesh sieve; 5.0g Cinnamomum camphora leaf powder is weighed in a 50mL three-necked bottle, and 15.0g of 1,3-di-sec-butylimidazolium chloride ionic liquid is added to control The temperature of the water bath is 30°C, the working frequency of the ultrasonic circulation extractor is 40KHz, the output power is 500W, and the ultrasonic-assisted extraction is 2 hours; after the extraction is completed, the oil-water mixture is obtained by distillation under reduced pressure, and the liquid is separated. The upper layer is cinnamon essential oil, which is extracted The extraction rate is 4.52%, which is 3.0 times of the steam distillation extraction rate (1.50%); the extracted essential oil components are analyzed by GC-MS, and the content of 1,8-cineole in the essential oil is 52.35%, which is the highest extraction rate of steam distillation. 1.6 times that of the law (32.65%).

Embodiment 2

[0028] Fresh cinnamon camphor leaves were crushed with a pulverizer and passed through a 20-mesh sieve; 5.0 g of cinnamon camphor leaf powder was weighed in a 50 mL three-necked bottle, and 15.0 g of 1,3-dipropenyl imidazolium bromide ionic liquid was added, and the water bath was controlled to The temperature is 40°C, the operating frequency of the ultrasonic circulation extractor is 40KHz, the output power is 500W, and the ultrasonic-assisted extraction is 2 hours; after the extraction is completed, the oil-water mixture is obtained by distillation under reduced pressure, and the upper layer is the essential oil of cinnamon camphor. 6.21%, which is 4.1 times of the steam distillation method extraction rate (1.50%); using GC-MS to analyze the extracted essential oil components, the content of 1,8-cineole in the essential oil is 58.92%, which is 4.1 times higher than that of the steam distillation method. 1.8 times that of (32.65%).

Embodiment 3

[0030] Fresh Cinnamomum camphora leaves are crushed with a pulverizer and passed through a 20-mesh sieve; 5.0g Cinnamomum camphora leaf powder is weighed in a 50mL three-necked bottle, and 20.0g of 1,3-diisobutylimidazole acetate ionic liquid is added to control The temperature of the water bath is 40°C, the working frequency of the ultrasonic circulation extractor is 40KHz, the output power is 500W, and the ultrasonic-assisted extraction is 3 hours; after the extraction is completed, the oil-water mixture is obtained by distillation under reduced pressure, and the liquid is separated. The upper layer is the essential oil of cinnamon camphor. The extraction rate is 7.10%, which is 4.7 times of the steam distillation extraction rate (1.50%); the extracted essential oil components are analyzed by GC-MS, and the content of 1,8-cineole in the essential oil is 60.07%, which is the highest extraction rate of steam distillation. 1.8 times that of the law (32.65%).

[0031] A typical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com