Preparation method of solid-phase microextraction head with multi-layer porous activated carbon film coating

A solid-phase micro-extraction head, activated carbon technology, applied in chemical instruments and methods, other chemical processes, instruments, etc., can solve the problems of requiring a cold trap device, time-consuming, complicated operation, etc., and achieves short analysis time, porosity The effect of high rate and strong enrichment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

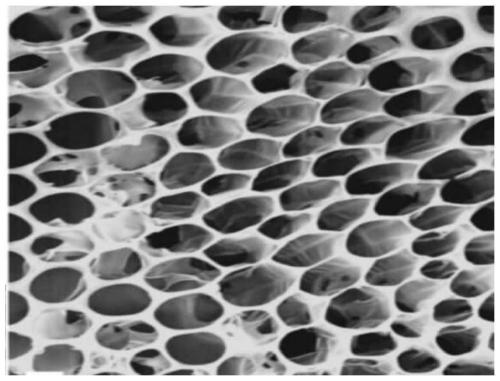

Image

Examples

Embodiment 1

[0026] The preparation method of a kind of solid-phase microextraction head of multi-layer porous activated carbon membrane coating that this embodiment relates to specifically comprises the following steps:

[0027] 1. Dissolve 0.05g polyacrylonitrile in 9.95g ternary mixed solvent, in which N,N-dimethylformamide:tetrahydrofuran:dichloromethane=1:1:2 in the ternary solvent, stir magnetically for 3h at room temperature , prepared into a polyacrylonitrile solution with a mass concentration of 0.5%.

[0028] 2. Corrode the stainless steel wire in a hydrofluoric acid solution with a mass fraction of 2% for 30 minutes, wash it with distilled water until neutral, and dry it to obtain a surface-modified stainless steel wire. Insert the surface-modified stainless steel wire into the above solution, soak in the solution for 5 minutes, then quickly take it out and put it into a closed container with a temperature and humidity of 20°C and 75% R.H. respectively, and keep it for 10 minute...

Embodiment 2

[0040] The preparation method of a kind of solid-phase microextraction head of multi-layer porous activated carbon membrane coating that this embodiment relates to specifically comprises the following steps:

[0041] 1. Dissolve 0.1g polyacrylonitrile in 9.9g ternary mixed solvent, in which N,N-dimethylformamide:tetrahydrofuran:dichloromethane=1:2:2 in the ternary solvent, stir magnetically for 3h at room temperature , prepared into a polyacrylonitrile solution with a mass concentration of 1%.

[0042] 2. Corrode the stainless steel wire in a hydrofluoric acid solution with a mass fraction of 2% for 30 minutes, wash it with distilled water until neutral, and dry it to obtain a surface-modified stainless steel wire. Insert the surface-modified stainless steel wire into the above solution, soak in the solution for 5 minutes, then quickly take it out and put it into a closed container with a temperature and humidity of 20°C and 75% R.H. respectively, and keep it for 10 minutes. ...

Embodiment 3

[0054] The preparation method of a kind of solid-phase microextraction head of multi-layer porous activated carbon membrane coating that this embodiment relates to specifically comprises the following steps:

[0055] 1. Dissolve 0.1g polyacrylonitrile in 9.9g ternary mixed solvent, in which N,N-dimethylformamide:tetrahydrofuran:dichloromethane=1:3:3 in the ternary solvent, stir magnetically for 3h at room temperature , prepared into a polyacrylonitrile solution with a mass concentration of 1%.

[0056] 2. Corrode the stainless steel wire in a hydrofluoric acid solution with a mass fraction of 2% for 30 minutes, wash it with distilled water until neutral, and dry it to obtain a surface-modified stainless steel wire. Insert the surface-modified stainless steel wire into the above solution, soak in the solution for 5 minutes, then quickly take it out and put it into a closed container with a temperature and humidity of 30°C and 83% R.H. respectively, and keep it for 10 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com