An explosion-proof broadband wave-absorbing composite material and its preparation method

A technology of composite materials and wave-absorbing materials, which is applied in the field of multi-functional materials, can solve the problems of not taking broadband wave-absorbing performance into account, having no explosion-proof performance, and being unable to realize explosion-proof and broadband wave-absorbing at the same time, and achieve excellent explosion-proof characteristics, dielectric The effect of low constants and overcoming technical obstacles that are difficult to combine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of this explosion-proof broadband absorbing composite material includes:

[0027] Step S1: Use quartz fiber and unsaturated resin to prepare explosion-proof skin.

[0028] The explosion-proof skin is a surface layer of composite material, which has an explosion-proof function in structure and a transmission electromagnetic wave characteristic in terms of absorbing function.

[0029] At present, the most widely used explosion-proof materials are para-aramid fiber (P-ARF), ultra-high molecular weight polyethylene (UHMWPE), and high-strength quartz fiber. In addition, there are more expensive polyparaphenylene benzodi Oxazole (PBO) and pyridine aramid fiber (M-5) can only be used in special fields.

[0030] Explosion-proof skin preparation method: cut para-aramid fiber (P-ARF), high-strength quartz fiber and ultra-high molecular weight polyethylene according to specifications, paint unsaturated resin between the explosion-proof materials, and put it into a m...

Embodiment 1

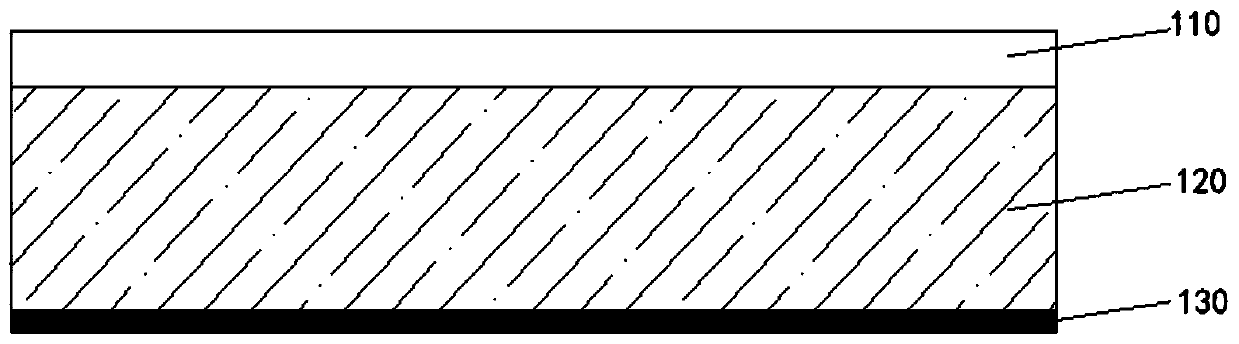

[0054] This embodiment provides an explosion-proof broadband wave absorbing composite material, which is a layered structure and includes a reflective substrate, a broadband sandwich wave absorbing material, and an explosion-proof skin that are in contact in sequence.

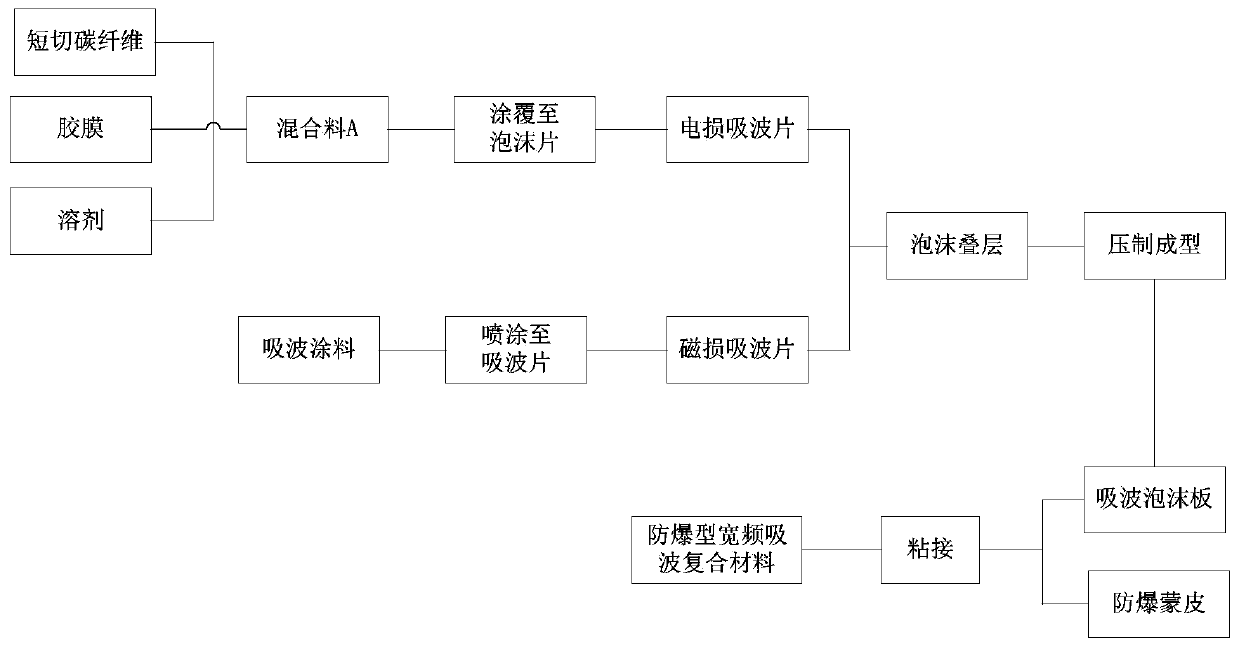

[0055] The process of its preparation method is as figure 2 As shown, specifically including:

[0056] 1). Preparation of explosion-proof skin:

[0057] 2). Preparation of broadband sandwich absorbing materials:

[0058] a. Using chopped carbon fiber as a wave absorber, put the chopped carbon fiber into a crucible, put it into a high-temperature curing furnace, and heat it at 400°C for 4 hours. Take out the chopped carbon fiber and soak it in concentrated sulfuric acid for 1 hour, remove the concentrated sulfuric acid and wash it 3 times with acetone, and place the cleaned chopped carbon fiber on filter paper to dry naturally for 24 hours.

[0059] b. Prepare the tetrahydrofuran, acetone and epoxy adhesive film into a ...

Embodiment 2

[0067] This embodiment provides an explosion-proof broadband wave absorbing composite material, which is a layered structure and includes a reflective substrate, a broadband sandwich wave absorbing material, and an explosion-proof skin that are in contact in sequence.

[0068] The preparation method is basically the same as that of Example 1, except that:

[0069] 2). Preparation of broadband sandwich absorbing materials:

[0070] a. Using carbon nanotubes as a wave absorbing agent, put the carbon nanotubes into a crucible, put it into a high-temperature curing furnace, and heat at 500°C for 3 hours. The carbon nanotubes were taken out and soaked in concentrated sulfuric acid for 0.5 hours, the concentrated sulfuric acid was removed and washed with acetone 3 times, and the cleaned carbon nanotubes were placed on filter paper to dry naturally for 24 hours.

[0071] b. Prepare the tetrahydrofuran, acetone and epoxy adhesive film into a glue solution according to a mass ratio of 1.2:1.2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com