Method for preparing iron-containing nanoparticles

A technology of iron nanoparticles and particles, which is applied in the field of preparation of iron-containing nanoparticles, can solve the problems of small amount of one-time preparation, low reaction efficiency, and poor particle size dispersion of nanoparticles, so as to improve the reaction surface renewal rate, good dispersibility, The effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

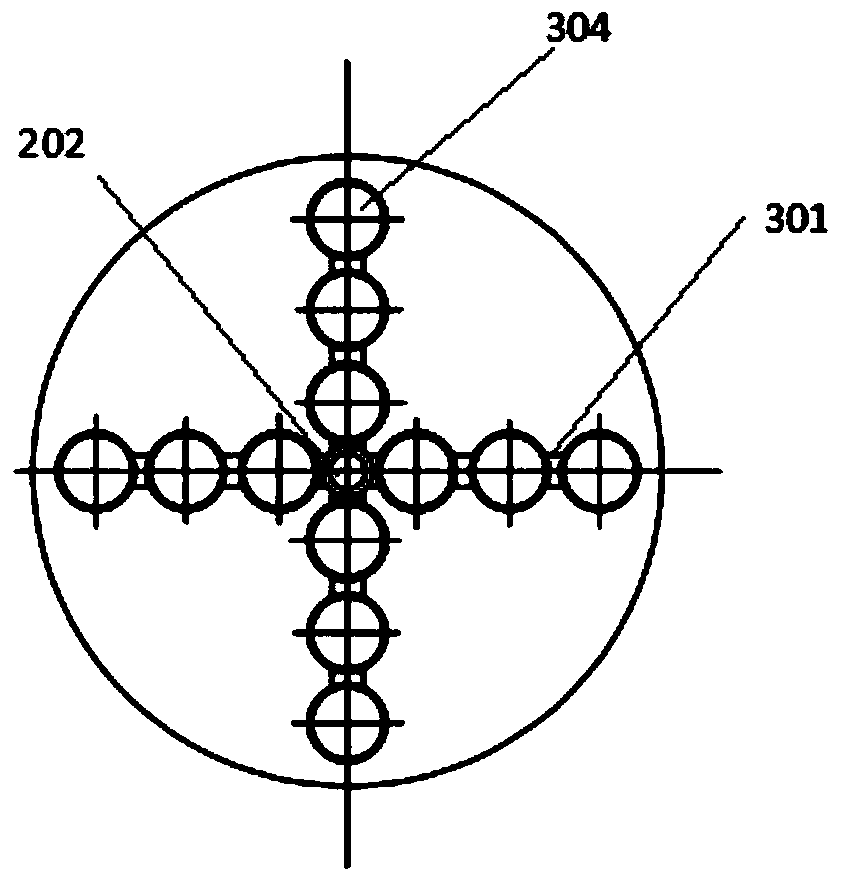

Image

Examples

Embodiment 1

[0029] Add 50kg water in 100L glass reactor, add 4.6kg ferrous sulfate (100% FeSO 4 ·7H 2 (0), 2kg liquid caustic soda (30%) and 15g polydimethylsiloxane are made into the reaction solution that pH is 12, pass into air 0.05m through titanium particle sintered aeration stone then 3 / min, react for 1 hour, filter, wash and dry the reaction solution to obtain the iron-containing nanoparticles, which are brown Fe 2 o 3 ·nH 2 960 g of O (n=0-8) nanoparticles, the particle diameter of which is 3-5 nanometers.

[0030] Titanium particle sintered aeration stone adopts TA1 titanium sintered product of Baoji Hongxinyuan Metal Material Co., Ltd.

Embodiment 2

[0032] Add 600kg water in 1000L enamel reactor, add 45kg ferrous chloride (100% FeCl 2 4H 2 (2), 36kg liquid caustic soda (30%) and 250g polymethylphenylsiloxane are mixed with the reaction solution that pH value is 3.5, pass into air 0.5m by corundum sintered aeration stone then 3 / min, after reacting for 45min, filter, wash and dry the reaction solution to obtain the iron-containing nanoparticles, which are 10.8kg of yellow FeOOH nanoparticles with a particle size of 8 to 10 nanometers. . The corundum sintered aeration stone is the brand 300 flat brown corundum aerator of Wuxi Jineng Environmental Protection Company.

Embodiment 3

[0034] at 10m 3 Add 7t of water in the glass fiber reinforced plastic reactor, add 300kg ferrous nitrate (100%Fe(NO) under stirring 3 ) 2 ), 450kg liquid caustic soda (30%) and 4000g acryl polyether modified polysiloxane are prepared into a reaction solution with a pH value of 8, and then pass air through the plastic microporous aeration head for 10m 3 / min, after reacting for 3 hours, the reaction solution is filtered, washed and dried to obtain the described iron-containing nanoparticles, which are black Fe 3 o 4 100 kg of nanoparticles, the particle diameter of which is 20-25 nanometers. The plastic microporous aeration head adopts the product of Wuxi Jineng Environmental Protection Company's brand name 215 rubber disc diaphragm microporous aerator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com