Integrated whole autotrophic nitrogen removal device

A full-process autotrophic denitrification and ontology technology, which is applied in the field of integrated full-process autotrophic denitrification devices, can solve the problems of denitrification performance and operation stability limitation, limit denitrification performance, and increase operating costs, and achieve rapid start-up and operation. The effect of stable operation, reducing aeration energy consumption, and increasing the amount of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

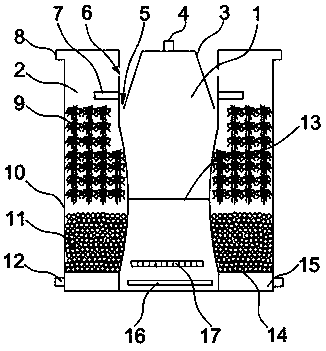

[0024] Such as figure 1 , 2 As shown, an integrated full-process autotrophic denitrification device includes a body 10. A granular sludge chamber 1 and an anaerobic sludge-biofilm chamber 2 are arranged inside the body 10. The granular sludge chamber 1 is sequentially arranged from bottom to top. Inlet water distributor 16, aeration pipe 17 and partition plate 13, anaerobic sludge-biofilm chamber 2 are respectively provided with hanging packing layer 9, accumulation packing layer 11 and water outlet chamber 15 from top to bottom, anaerobic sewage The mud-biofilm chamber 2 is arranged around the outside of the granular sludge chamber 1. The granular sludge chamber 1 is divided into upper and lower parts by a partition plate 13. The upper part is provided with a gas collection hood 3, and the end face of the gas collection hood 3 is provided with a first gas outlet. 4. The upper part of the inner wall of the granular sludge chamber 1 is provided with an annular overflow port 6 ...

Embodiment 2

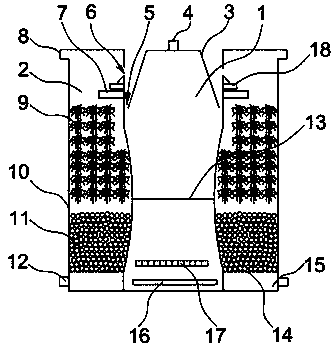

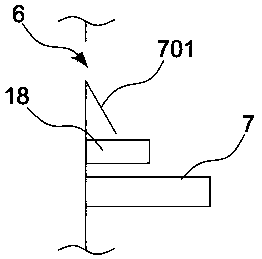

[0031] Such as image 3 , 4 As shown, the further optimization scheme of this embodiment on the basis of Embodiment 1 is: the inner wall of the anaerobic sludge-biofilm chamber 2 is obliquely surrounded and connected with a deflector 701, and the deflector 701 is flush with the bottom surface of the overflow port 6, The deflector 701 is located above the buffer 18, and the buffer 18 is located above the water distributor 7. Using the deflector 701, the wastewater enters the anaerobic sludge-biofilm chamber 2 and fully contacts with the outside air to reduce the oxygen concentration in the wastewater. , to prevent concentrated wastewater from flowing down from the inner wall of the anaerobic sludge-biofilm chamber 2, resulting in uneven distribution of wastewater in the anaerobic sludge-biofilm chamber 2, affecting the effect of denitrification and the corrosive effect on the inner wall, and then using water distribution The device 7 evenly distributes the waste water and flow...

Embodiment 3

[0034] Such as Figure 5 As shown, the further optimization scheme of this embodiment on the basis of embodiment 1 is:

[0035]The surface of the partition plate 13 is preferably evenly distributed with gas-liquid flow holes 13a with a diameter of 3 cm. The ratio of the total area of the round holes to the total area of the partition plate 13 is preferably 0.75:1, and the gas-liquid flow holes 13a on the surface of the partition plate 1 The gas input by the aeration pipe 17 at the bottom is further dispersed evenly to avoid excessive concentration of air bubbles, which is not easy to reproduce and grow aerobic ammonia oxidizing bacteria on the surface of the granular sludge. The surface of the partition plate 13 is evenly distributed with gas-liquid flow holes 13a, and a cross bar 13b is arranged at the bottom of the gas-liquid flow hole 13a, and the lower part of the cross bar 13b is connected with a diverter ball 13c through a connecting rod, and the surface of the diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com