Steel fiber reinforced internal curing high-strength silicate ceramsite and preparation method thereof

A technology of steel fiber and silicate, which is applied in the field of high-strength silicate ceramsite and its preparation, can solve the problems of large drying shrinkage of high-strength concrete, restrictions on the development and promotion of high-strength lightweight concrete, and low water absorption, so as to reduce CO2 emissions , good strain coordination performance, and the effect of suppressing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

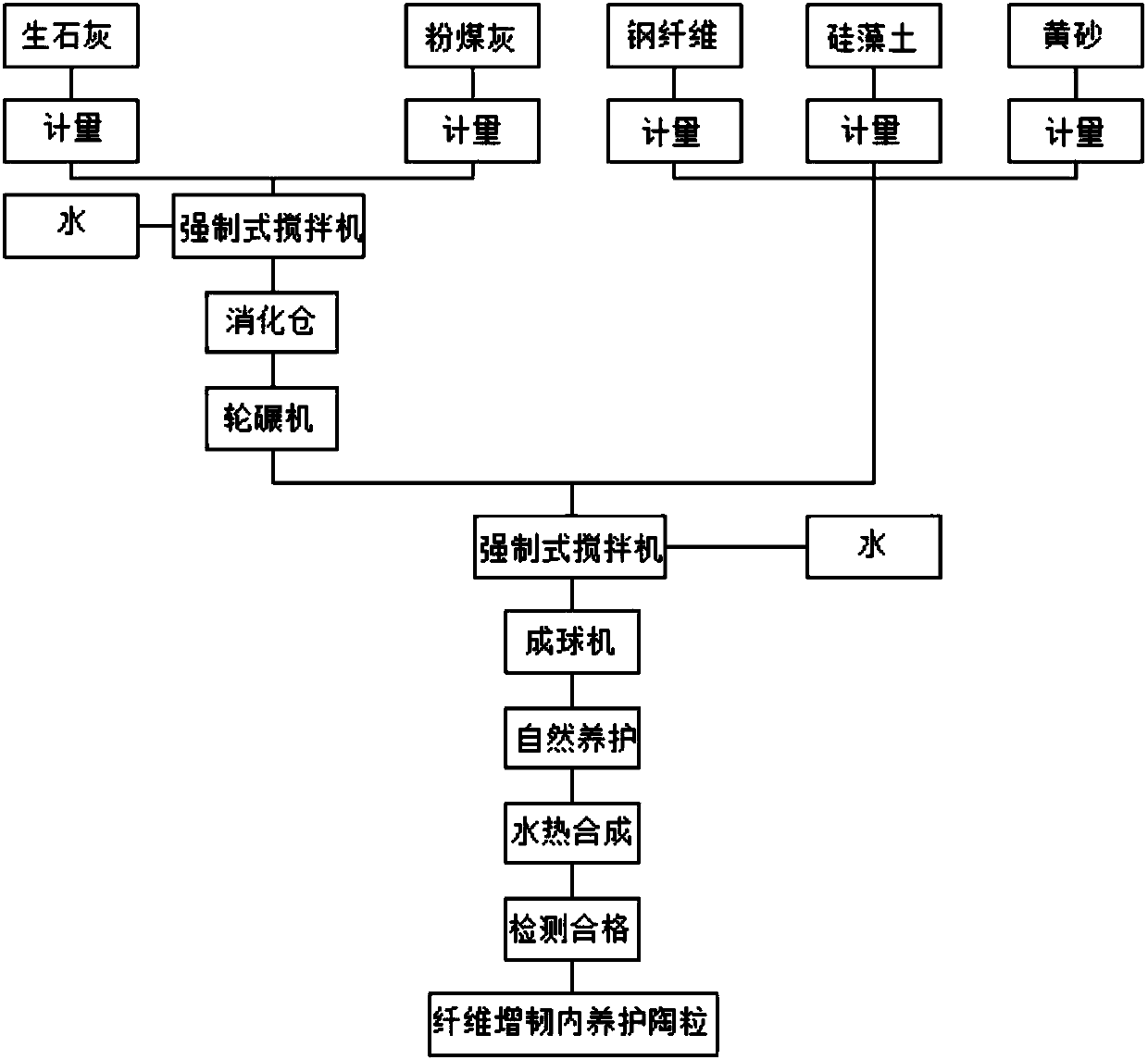

[0045] combine figure 2 , in this embodiment, the quicklime A-CaO is 70%, and the steel fiber volume ratio is 0.5%; quicklime: fly ash: diatomaceous earth: yellow sand=25.5:39.5:20:15; the cylinder compressive strength of the prepared ceramsite is 12MPa~16MPa, 1h water absorption rate is 15%~22%;

[0046] Step 1: Put 152.9kg of quicklime and 237.1kg of fly ash into the forced mixer, spray 15.3kg of water (the water quality accounts for 10% of the quicklime mass) while stirring, and unload when the materials are mixed evenly and appear wet Digest for 3 hours in the digestion bin, and make digested material for later use;

[0047] The second step: Put the digested material prepared in the first step into the wheel mill and grind it for 3min to 5min. After there are no obvious agglomerated particles, add it to the forced mixer together with 90kg of yellow sand and spray 50.7kg of water at the same time (the water quality accounts for the digestion 13% of the material quality) ...

Embodiment 2

[0053] combine figure 2 , in this embodiment, the quicklime A-CaO is 75%, and the steel fiber volume ratio is 1.5%; quicklime: fly ash: diatomaceous earth: yellow sand=25.6:36.4:25:13; the cylinder compressive strength of the prepared ceramsite is 18MPa~22MPa, 1h water absorption rate is 23%~25%;

[0054] Step 1: Put 153.6kg of quicklime and 218.4kg of fly ash into the forced mixer, spray 15.4kg of water while stirring (the water quality accounts for 10% of the quicklime mass), and when the materials are mixed evenly and appear wet, unload Digest in the digestion chamber for 4 hours, and make digested material for later use;

[0055] Step 2: Put the digested material prepared in the first step into the wheel mill and grind it for 3-5 minutes. After there are no obvious agglomerated particles, add it to the forced mixer together with 78kg of yellow sand and spray 55.8kg of water at the same time (the water quality accounts for the digestion 15% of the material quality) and s...

Embodiment 3

[0061] combine figure 2 , in this embodiment, the quicklime A-CaO is 80%, and the steel fiber volume ratio is 1.5%; quicklime: fly ash: diatomaceous earth: yellow sand=25.9:34.1:30:10; the cylinder compressive strength of the prepared ceramsite is 18MPa~22MPa, 1h water absorption 26%~30%;

[0062] Step 1: Put 155.2kg of quicklime and 204.8kg of fly ash into a forced mixer, and spray 23.3kg of water (the water quality accounts for 15% of the quicklime mass) while stirring. When the materials are mixed evenly and appear wet, unload Digest in the digestion chamber for 4 hours, and make digested material for later use;

[0063] Step 2: Put the digested material prepared in the first step into the wheel mill and grind for 3-5 minutes. After there are no obvious agglomerated particles, add it to the forced mixer together with 60kg of yellow sand and spray 54kg of water at the same time (the water quality accounts for the digested material. mass 15%) and stir for 3min to 4min. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com