Preparation method for composite rubber mat

A composite rubber and natural rubber technology, which is applied in sea area engineering, coastline protection, jetty, etc., can solve the problems of shortened service life, poor resistance to seawater corrosion, sand and stone friction, and easy aging, etc., to achieve long service life, The effect of wave and sound elimination is obvious, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of a composite rubber pad, comprising the following steps:

[0052]Step1, mix natural rubber, nitrile rubber, tetrapropylene fluorine rubber, sodium stearate, triallyl isocyanurate, polyvinylidene fluoride, methylol fatty amine, dicumyl peroxide, titanic acid Ester coupling agent, filler and plasticizer are poured into a pressurized rubber kneader, pressed at 120-130°C for 10 minutes, and discharged to obtain mixture A;

[0053] Step2, add nickel-based alloy, far-infrared ceramic powder, titanium alloy, aminosilane and thermoplastic polyurethane elastomer into the ultrasonic disperser for dispersion, the ultrasonic power is 180-200W, the dispersion time is 15-20 minutes, and the dispersion temperature is 120- 140°C, mixture B was obtained;

[0054] Step3, fully stir the mixture A and the mixture B evenly, then pour into the internal mixer, under the condition of 140-150 ℃, banbury at the speed of 800-950 rpm for half an hour, to obtain the mixture ...

Embodiment 2

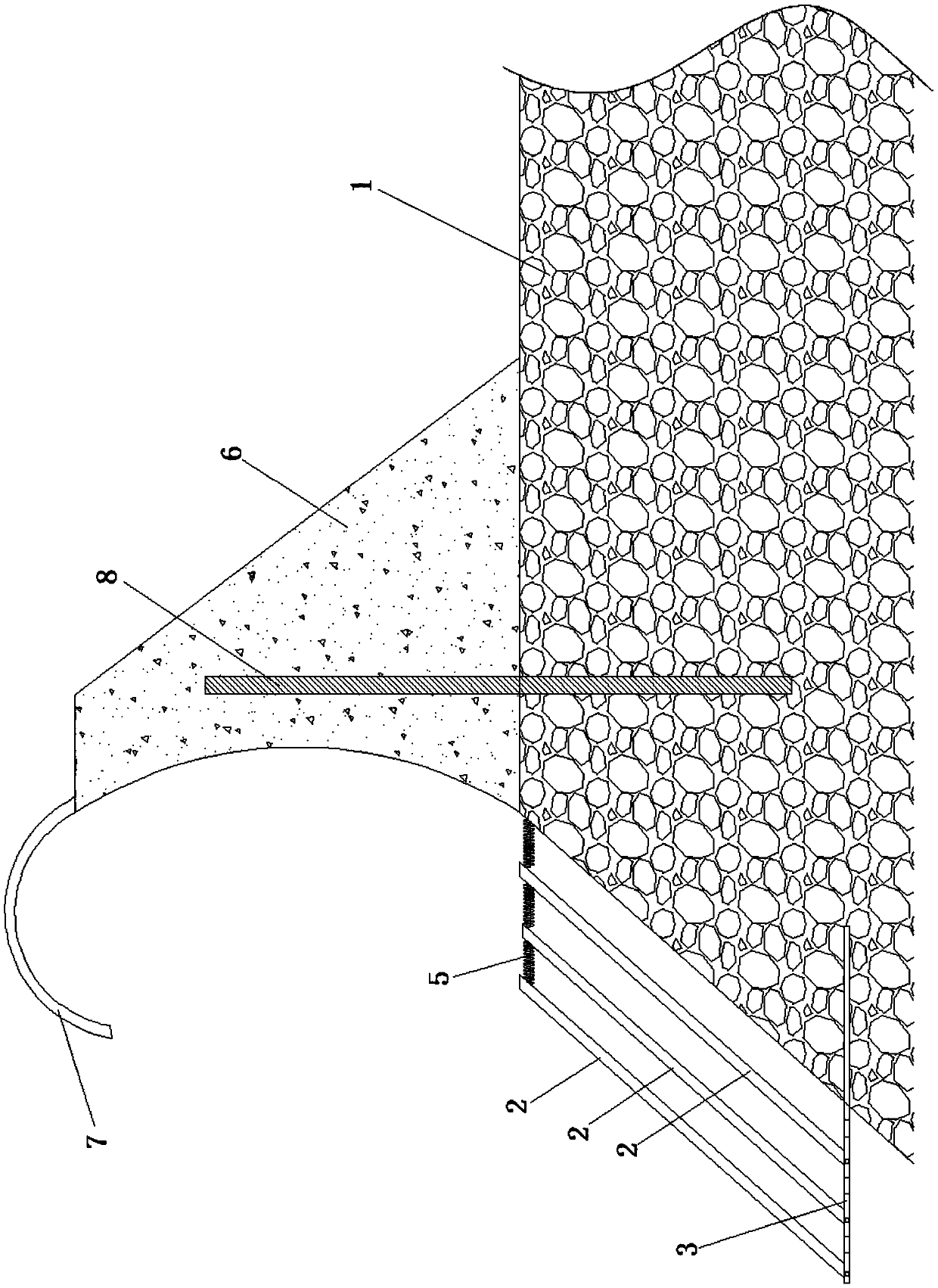

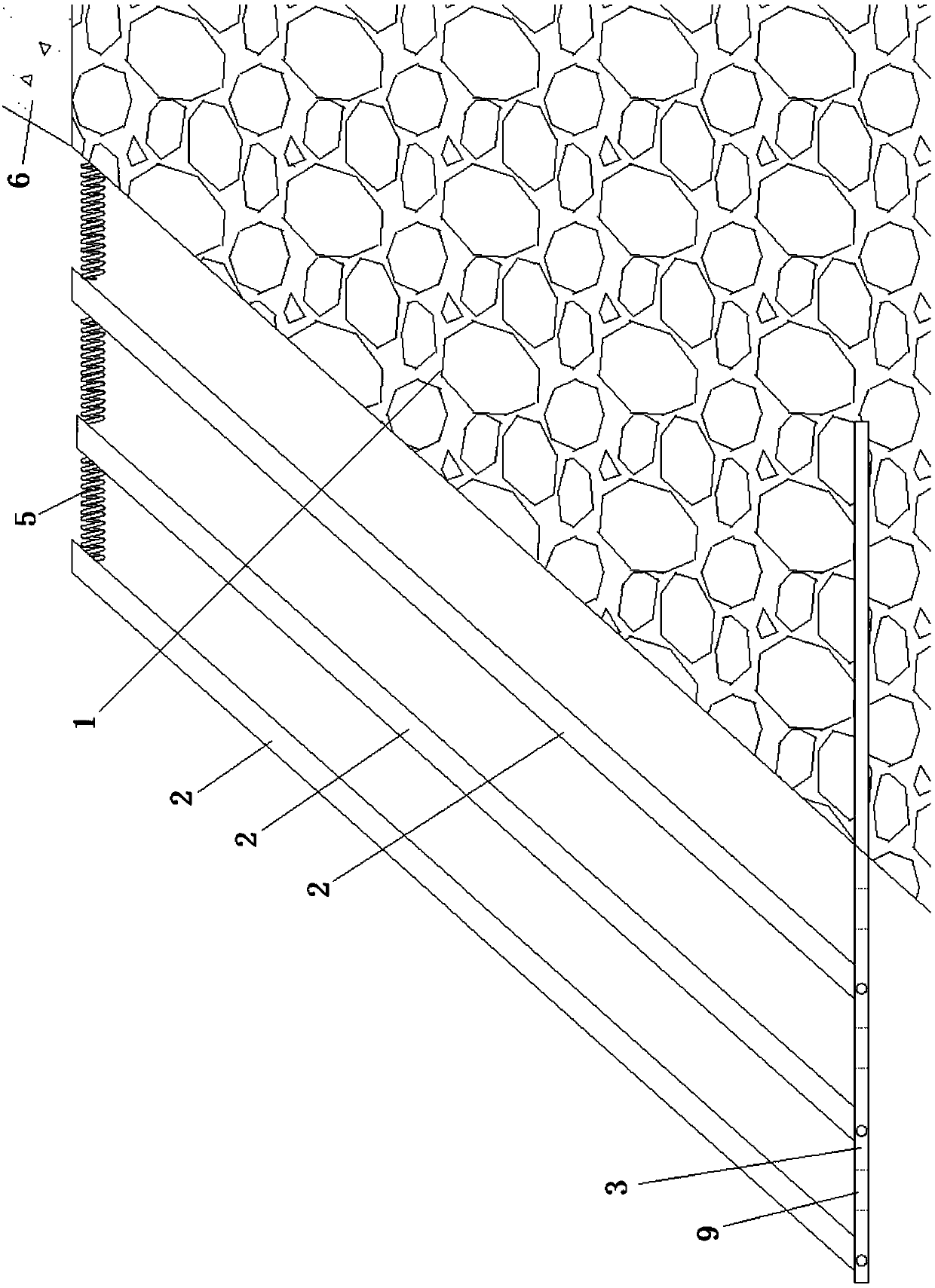

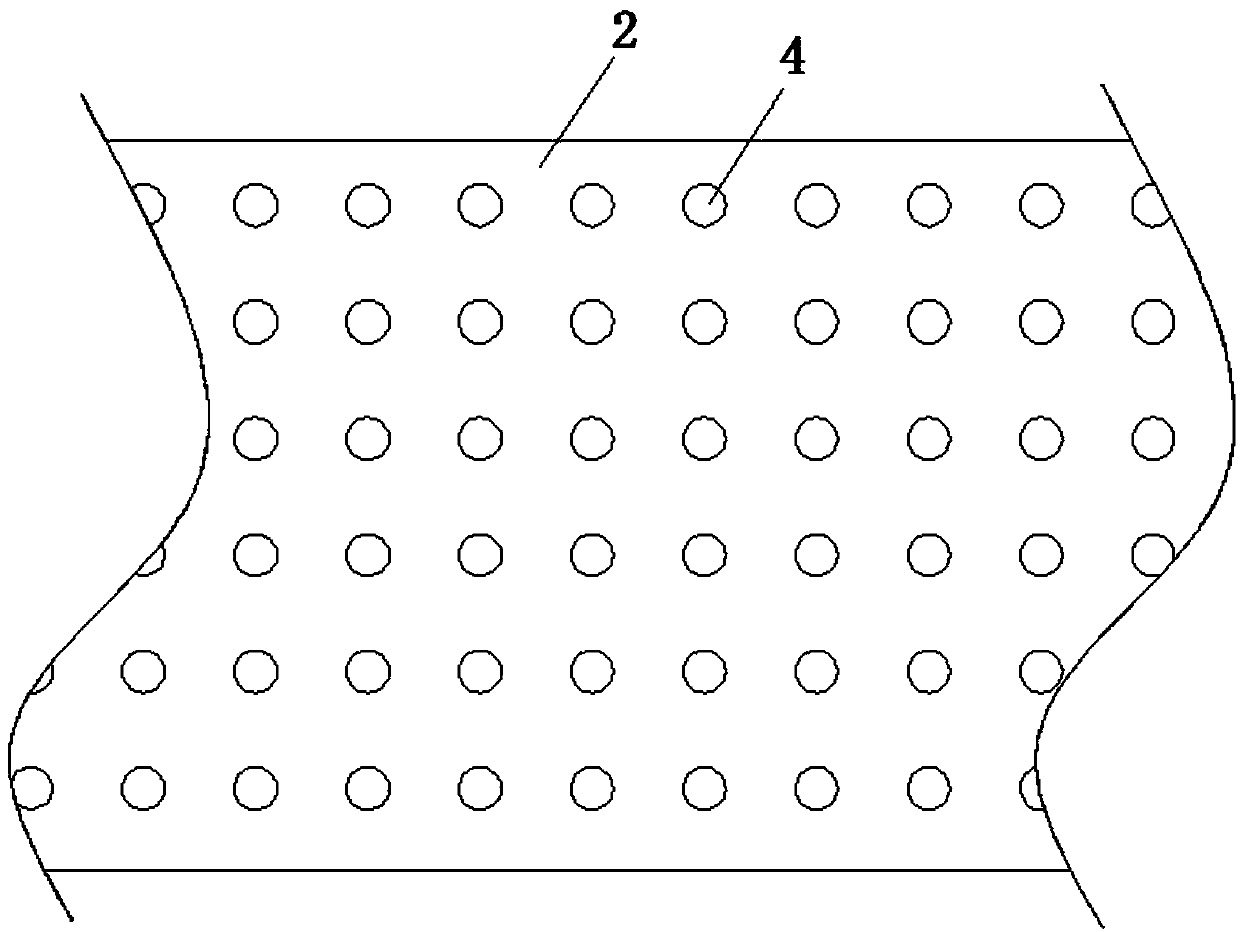

[0067] A sound-absorbing and anti-wave wall structure, comprising a dam foundation 1, the water-facing surface of the dam foundation 1 is an inclined surface, and several inclined rubber pads 2 are arranged on the water-facing surface of the dam foundation 1, and the inclined rubber pads 2 are arranged in parallel at equal intervals, The inclined rubber pad 2 is axially connected to the steel plate 3 below it, and the right end of the steel plate 3 is fixed inside the dam foundation 1. The inclined rubber pad 2 is provided with evenly distributed through holes 4, and the adjacent inclined rubber pads The top of 2 is connected by a spring 5. The top of the dam foundation 1 facing the water is provided with a wave-proof wall 6. A semicircular arc-shaped anti-wave cover 7 with an opening downward is provided.

[0068] Further, the water-facing surface of the dam foundation 1 is tangent to the water-facing surface of the anti-wave wall 6 .

[0069] Further, the water-facing surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com