A kind of antibacterial masterbatch and preparation method thereof

An antibacterial masterbatch and pelletizer technology, applied in rayon manufacturing, textile and papermaking, fiber chemical characteristics, etc., can solve problems such as large human injury, and achieve enhanced softness, gloss, flexibility, strength, and corrosion resistance. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

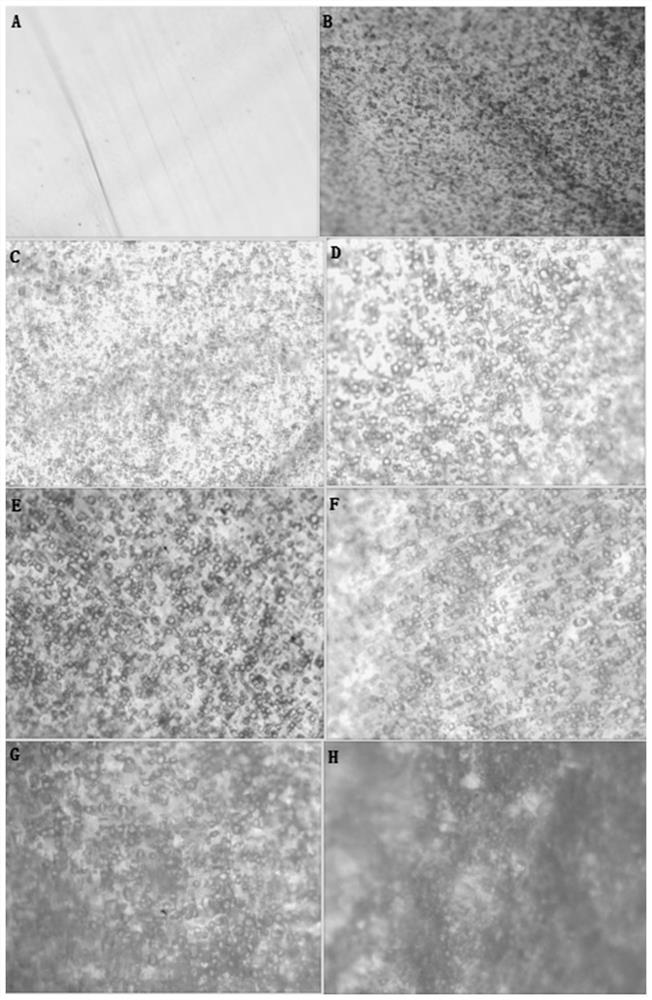

Image

Examples

Embodiment 1

[0020]Preparation of antibacterial patents

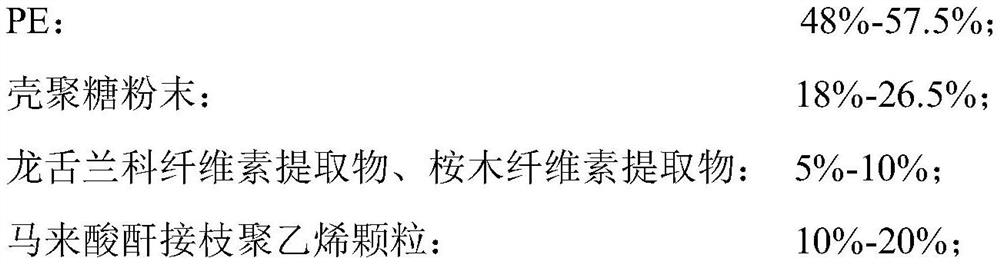

[0021]Antibacterial masterbatch raw material weight percentage, such as (number of parts):

[0022]

[0023]The preparation method is as follows:

[0024]S1), PE, chitosan powder, orchid cellulose extract of the above mass parts, pelletulose extract, maleic anhydride grafted polyethylene particles, epoxy resin, talc, compound Surfactant, environmentally friendly antioxidant is added to the mixer for 5-10 min to mix uniform;

[0025]S2), the molten spinning method is used through the twin screw extruder, and the cold water is cooled, dried, and then traces to the particulating machine for cutting to obtain antibacterial parenchula, wherein the host speed: 170-220 r / min is obtained. Feeding machine speed: 11-14R / min; particularging machine speed: 6.1-8.0R / min; double screw each area temperature is a zone: 105-115 ° C; Second District: 155-165 ° C; Three District: 155- 165 ° C; four districts: 165-175 ° C; five districts: 155-165 ° C; machine head: 1...

Embodiment 2

[0027]Preparation of antibacterial patents

[0028]Antibacterial masterbatch raw material weight percentage, such as (number of parts):

[0029]

[0030]The preparation method is as follows:

[0031]S1), PE, chitosan powder, orchid cellulose extract of the above mass parts, pelletulose extract, maleic anhydride grafted polyethylene particles, epoxy resin, talc, compound Surfactant, environmentally friendly antioxidant is added to the mixer for 5-10 min to mix uniform;

[0032]S2), the molten spinning method is used through the twin screw extruder, and the cold water is cooled, dried, and then traces to the particulating machine for cutting to obtain antibacterial parenchula, wherein the host speed: 170-220 r / min is obtained. Feeding machine speed: 11-14R / min; particularging machine speed: 6.1-8.0R / min; double screw each area temperature is a zone: 105-115 ° C; Second District: 155-165 ° C; Three District: 155- 165 ° C; four districts: 165-175 ° C; five districts: 155-165 ° C; machine head: 1...

Embodiment 3

[0034]Preparation of antibacterial patents

[0035]Antibacterial masterbatch raw material weight percentage, such as (number of parts):

[0036]

[0037]The preparation method is as follows:

[0038]S1), PE, chitosan powder, orchid cellulose extract of the above mass parts, pelletulose extract, maleic anhydride grafted polyethylene particles, epoxy resin, talc, compound Surfactant, environmentally friendly antioxidant is added to the mixer for 5-10 min to mix uniform;

[0039]S2), the molten spinning method is used through the twin screw extruder, and the cold water is cooled, dried, and then traces to the particulating machine for cutting to obtain antibacterial parenchula, wherein the host speed: 170-220 r / min is obtained. Feeding machine speed: 11-14R / min; particularging machine speed: 6.1-8.0R / min; double screw each area temperature is a zone: 105-115 ° C; Second District: 155-165 ° C; Three District: 155- 165 ° C; four districts: 165-175 ° C; five districts: 155-165 ° C; machine head: 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com