PC (polycarbonate) composite with high wear resistance and high strength and preparation method of PC composite

A technology of polycarbonate and composite materials, which is applied in the field of high wear-resistant and high-strength polycarbonate composite materials and its preparation, can solve the problems of insufficient wear resistance and mechanical properties, achieve excellent physical and mechanical properties, improve adhesion, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

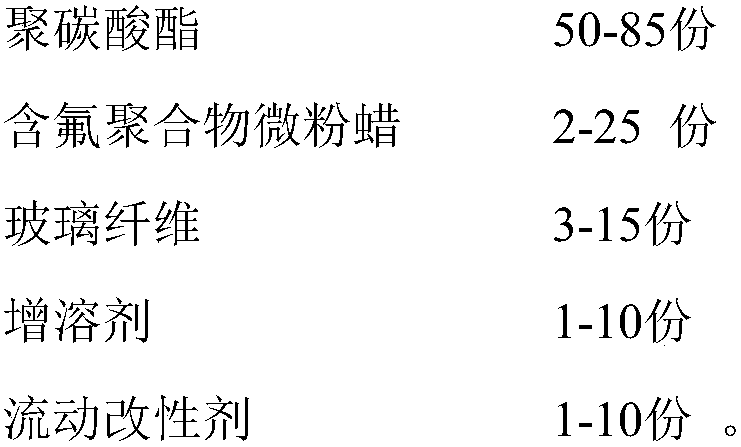

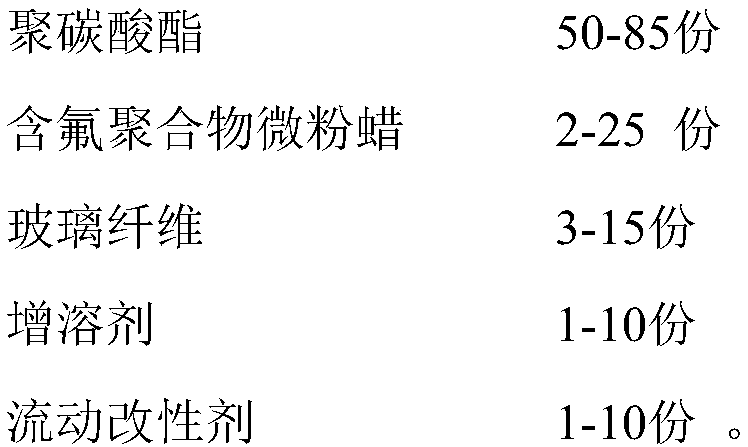

[0023] The mass ratio of raw materials in this embodiment is: 80 parts of polycarbonate, 10 parts of polytetrafluoroethylene micropowder wax (average particle diameter 5 μm), 2 parts of nano silicon dioxide, 3 parts of solubilizer, 5 parts of glass fiber roving share.

[0024] Preparation:

[0025] (1) Weigh the raw materials polycarbonate, polytetrafluoroethylene micropowder wax, nano-silica, and solubilizer according to the above ratio, and add them to a high-speed mixer and mix for about 30 minutes;

[0026] (2) Put the mixture obtained in step (1) into the hopper of the extruder, and the glass fiber is fed into the extruder from the glass fiber inlet for co-extrusion granulation. The extrusion temperature is about: 260°C in the first zone and 275°C in the second zone , the third zone is 280°C, the fourth zone is 290°C, the fifth zone is 290°C, the sixth zone is 290°C, the seventh zone is 280°C;

[0027] (3) The pellets obtained in step (2) were injection-molded in an inj...

Embodiment 2

[0030] The mass ratio of raw materials in this embodiment is: 65 parts of polycarbonate, 15 parts of polytetrafluoroethylene micropowder wax (average particle size 5 μm), 3 parts of nano-mica, 5 parts of solubilizer, and 12 parts of glass fiber roving.

[0031] Preparation:

[0032] (1) Weigh the raw materials polycarbonate, polytetrafluoroethylene micro-powder wax, nano-mica, and solubilizer according to the above ratio, and add them to a high-speed mixer, and mix for about 30 minutes;

[0033] (2) Put the mixture obtained in step (1) into the hopper of the extruder, and the glass fiber is fed into the extruder from the glass fiber inlet for co-extrusion granulation. The extrusion temperature is about: 270°C in the first zone and 285°C in the second zone , the third zone is 290°C, the fourth zone is 295°C, the fifth zone is 295°C, the sixth zone is 295°C, and the seventh zone is 295°C;

[0034] (3) Inject the pellets obtained in step (2) into an injection molding machine at ...

Embodiment 3

[0037] The mass ratio of raw materials in this embodiment is: 58 parts of polycarbonate, 20 parts of polytetrafluoroethylene micropowder wax (average particle size 5 μm), 3 parts of zirconium phosphate, 4 parts of solubilizer, and 15 parts of glass fiber roving.

[0038] Preparation:

[0039] (1) Weigh the raw materials polycarbonate, polytetrafluoroethylene micro-powder wax, zirconium phosphate, and solubilizer according to the above ratio, and add them to the high-speed mixer, and mix for about 30 minutes;

[0040] (2) Put the mixture obtained in step (1) into the hopper of the extruder, and the glass fiber is fed into the extruder from the glass fiber inlet for co-extrusion granulation. The extrusion temperature is about: 270°C in the first zone and 280°C in the second zone , the third zone is 290°C, the fourth zone is 295°C, the fifth zone is 295°C, the sixth zone is 295°C, and the seventh zone is 295°C;

[0041] (3) The pellets obtained in step (2) are injection-molded i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com