A kind of enrichment method of aroma components of Maillard reaction product for cigarettes

A technology of Maillard reactants and reactants, which is applied in the fields of tobacco, application, and treatment of tobacco, can solve problems such as the complex structure of the final product, and achieve the effect of rich smoke aroma, strong pertinence, and obvious aroma characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

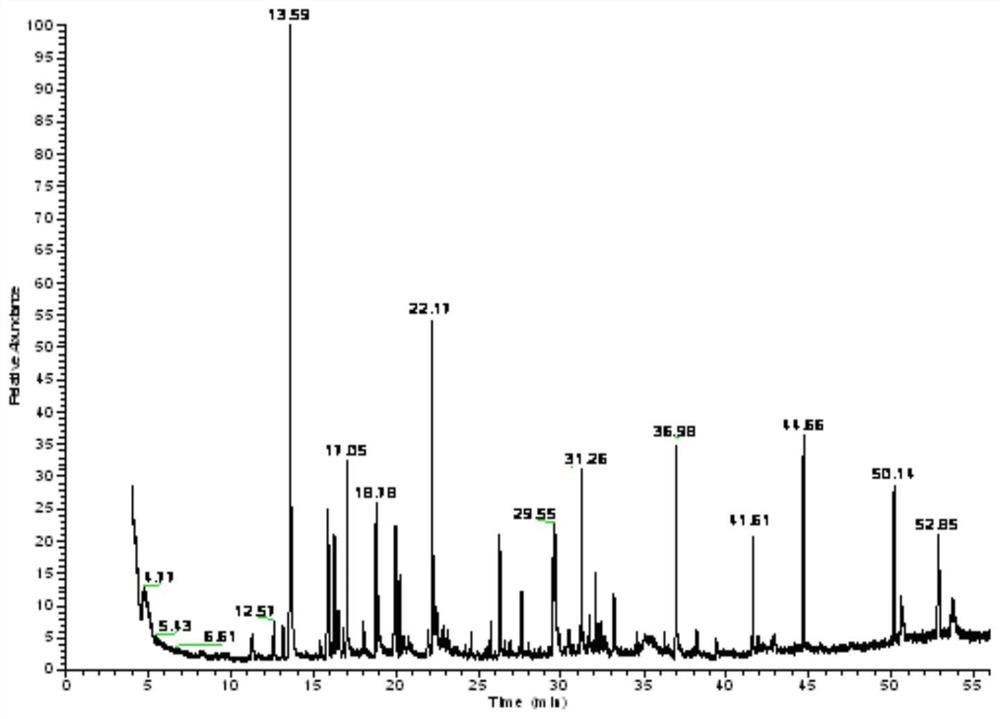

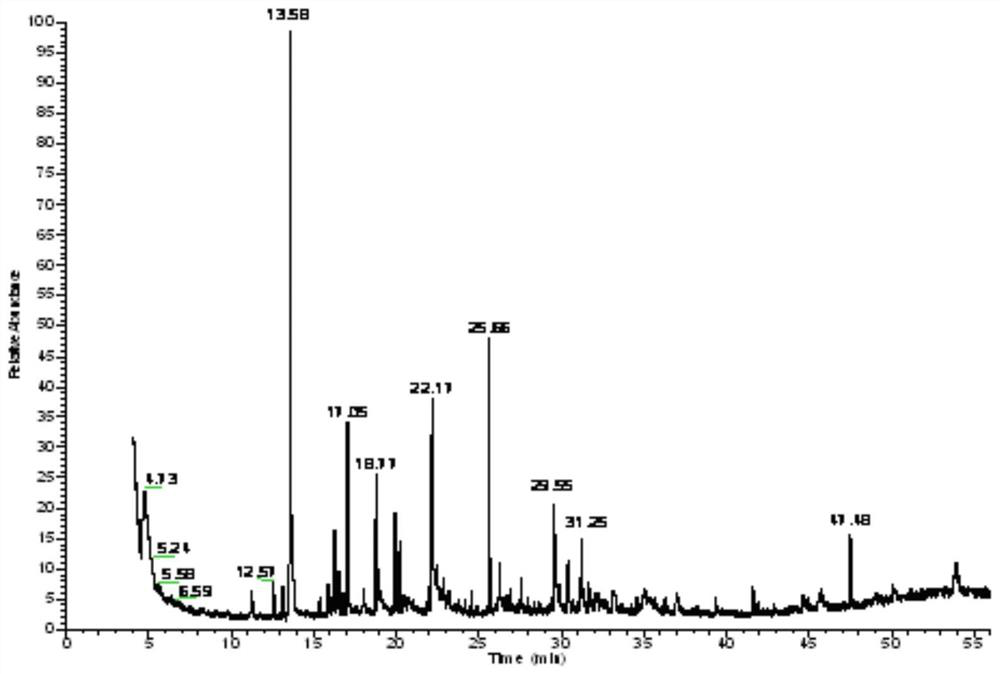

Image

Examples

Embodiment 1

[0018] Embodiment 1: a method for enriching aroma components of Maillard reaction products for cigarettes, characterized in that the specific steps include:

[0019] (1) Mix glucose, fructose mixture and glycine according to the molar concentration ratio of 2:1, and react for 4.5 hours at 100°C and pH 7.5 to prepare Maillard reactants;

[0020] (2) Concentrating the Maillard reactant prepared in step (1) under reduced pressure to a viscous semi-fluid state, adding 95% ethanol solution 6 times its weight, stirring evenly, and standing for 24 hours;

[0021] (3) The alcohol precipitation solution obtained in step (2) is filtered with a 100nm ceramic membrane, and the membrane filtrate is concentrated under reduced pressure to a relative density of 1.0800 to obtain a reactant absolute;

[0022] (4) The net oil of the reactant is subjected to molecular distillation separation treatment, the separation process parameters are: vacuum degree 1.8tor, feed rate 1.5mL / min, scraper speed...

Embodiment 2

[0026] Embodiment 2, a method for enriching aroma components of Maillard reaction products for cigarettes, is characterized in that the specific steps include:

[0027] (1) Mix the mixture of galactose, alanine and lysine according to the molar concentration ratio of 2:1.2, and react for 6 hours at 85°C and pH 8.5 to prepare Maillard reactant;

[0028] (2) Concentrating the Maillard reactant prepared in step (1) under reduced pressure to a viscous semi-fluid state, adding 95% ethanol solution 3 times its weight, stirring evenly, and standing for 40 hours;

[0029] (3) The alcohol precipitation solution obtained in step (2) is filtered by a 100nm ceramic membrane, and the membrane filtrate is concentrated under reduced pressure to a relative density of 1.0832 to obtain a reactant absolute;

[0030] (4) The net oil of the reactant is subjected to molecular distillation separation treatment, the separation process parameters are: vacuum degree 1.5tor, feed rate 1.8mL / min, scraper...

Embodiment 3

[0034] Embodiment 3, a method for enriching aroma components of Maillard reaction products for cigarettes, is characterized in that the specific steps include:

[0035] (1) Mix a mixture of fructose and lactose with glycine at a molar ratio of 1:1, and react for 3 hours at 105°C and pH 9.5 to prepare a Maillard reactant;

[0036] (2) Concentrating the Maillard reactant prepared in step (1) under reduced pressure to a viscous semi-fluid state, adding 95% ethanol solution 7 times its weight, stirring evenly, and standing for 24 hours;

[0037] (3) The alcohol precipitation solution obtained in step (2) is filtered by a 100nm ceramic membrane, and the membrane filtrate is concentrated under reduced pressure to a relative density of 1.0809 to obtain a reactant absolute;

[0038] (4) The net oil of the reactant is subjected to molecular distillation separation. The separation process parameters are: vacuum degree 2.0tor, feed rate 2mL / min, scraper speed 60r / min, distillation temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com