Preparation method of water-resistant wallpaper

A technology for wallpaper and preparation steps, which is applied in the field of preparation of water-resistant wallpaper, which can solve the problems of poor fire-proof and flame-retardant effects and inability to effectively prevent fire, and achieve the effects of improving stability, improving water resistance, and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

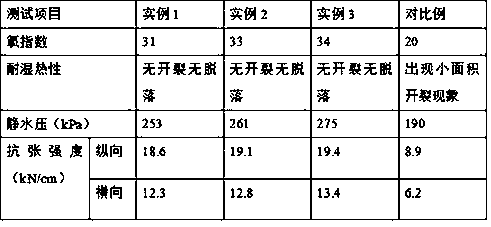

Examples

example 1

[0025] Take soybeans and place them in a mortar and mash them for 30 minutes, soak the mashed soybeans with absolute ethanol for 2 hours, filter, remove the filter residue, and obtain soybean extracts. In parts by weight, take 50 parts of butyl acrylate, 15 parts of methyl Put hydroxyethyl acrylate and 30 parts of styrene in a beaker and stir for 15 minutes to obtain a mixed monomer; take 8 mL of soybean extract, 90 mL of deionized water and 40 mL of a mixed monomer and mix and stir for 10 minutes to obtain a monomer pre-emulsion, and another 4 mL Soybean extract and 40mL deionized water were added to the four-necked flask as the reaction bottom solution; 4.5g of ammonium persulfate was dissolved in 25mL of deionized water to obtain the initiator, and the above-mentioned four-necked flask was moved into a water bath at 80°C. Add two-fifths of the monomer pre-emulsion and one-third of the initiator into the four-necked flask, stir and react, and after the blue phase appears in t...

example 2

[0027] Get soybeans and place them in a mortar and mash them for 35 minutes, soak the mashed soybeans with absolute ethanol for 2.5 hours, filter, remove the filter residue, and obtain soybean extracts. In parts by weight, take 55 parts of butyl acrylate, hydroxyethyl acrylate and 35 parts of styrene were placed in a beaker and stirred for 17 minutes to obtain a mixed monomer; 9 mL of soybean extract, 95 mL of deionized water and 45 mL of a mixed monomer were mixed and stirred for 13 minutes to obtain a monomer pre-emulsion, and another Add 4.5mL of soybean extract and 45mL of deionized water into a four-necked flask as the reaction bottom solution; dissolve 4.7g of ammonium persulfate in 28mL of deionized water to obtain an initiator, and move the above-mentioned four-necked flask into a water bath at 83°C , add two-fifths of the monomer pre-emulsion and one-third of the initiator in the four-necked flask, stir the reaction, and after the blue phase appears in the reaction, ad...

example 3

[0029] Put the soybeans in a mortar and mash them for 40 minutes, soak the mashed soybeans with absolute ethanol for 3 hours, filter, remove the filter residue, and obtain the soybean extract. In parts by weight, take 60 parts of butyl acrylate, 20 parts of methyl Put hydroxyethyl acrylate and 40 parts of styrene in a beaker and stir for 20 minutes to obtain a mixed monomer; take 10 mL of soybean extract, 100 mL of deionized water and 50 mL of a mixed monomer and mix and stir for 15 minutes to obtain a monomer pre-emulsion, and another 5 mL Soybean extract and 50 mL of deionized water were added to a four-necked flask as the reaction bottom solution; 5.0 g of ammonium persulfate was dissolved in 30 mL of deionized water to obtain an initiator, and the above-mentioned four-necked flask was moved into a water bath at 85 °C, and Add two-fifths of the monomer pre-emulsion and one-third of the initiator in the four-necked flask, stir the reaction, and after the blue phase appears in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com