A low-cost and rapid mass-fabrication method for integrated micro-thin-film thermoelectric devices

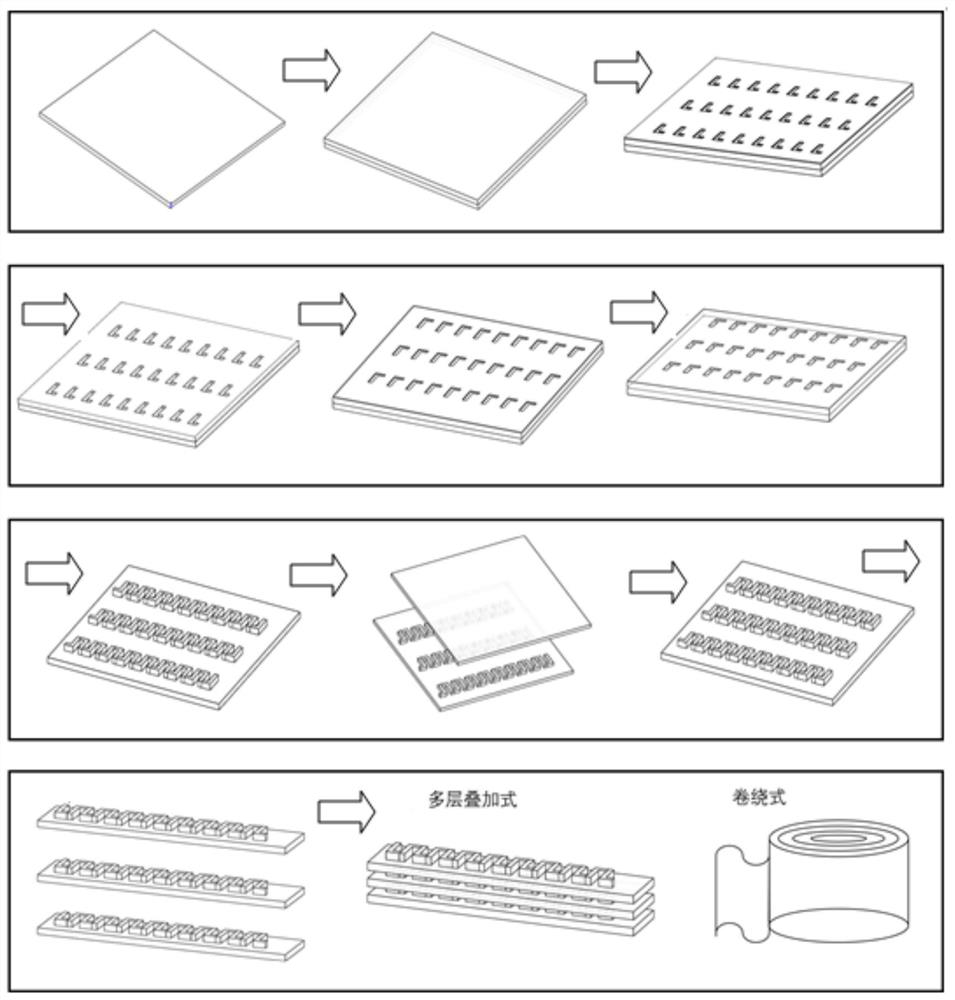

A technology for thermoelectric devices and manufacturing methods, which is applied in the manufacture/processing of thermoelectric devices, instruments, opto-mechanical equipment, etc., and can solve the problems of inapplicability to micro-thin film thermoelectric devices, complex lithography preparation process, and not reaching the micron level. , to achieve the effect of reducing preparation cost, broad application prospect and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In the present invention, a 200 μm thick stainless steel plate is selected as the conductive base material, and Ordyl-50100 negative acrylate polymer-based dry film negative photoresist is selected as an electroplating template to replace the SU8 negative epoxy resin-based liquid photoresist. Ordyl-50100 is easy to handle and easy to remove later. Concrete preparation process is as follows:

[0056] (1) Ultrasonic cleaning, degreasing, drying and insulation of single-sided tape on the stainless steel plate of the conductive base material;

[0057] (2) The photoresist template can be heated and pressurized by using a laminating machine or equipment with a hot roller. The pressure of the hot roller is 310Kpa, and the lamination speed is set to 40cm min -1 , the equipment temperature is set to 100°C, so that the dry film melts and sticks to the stainless steel plate of the conductive base material;

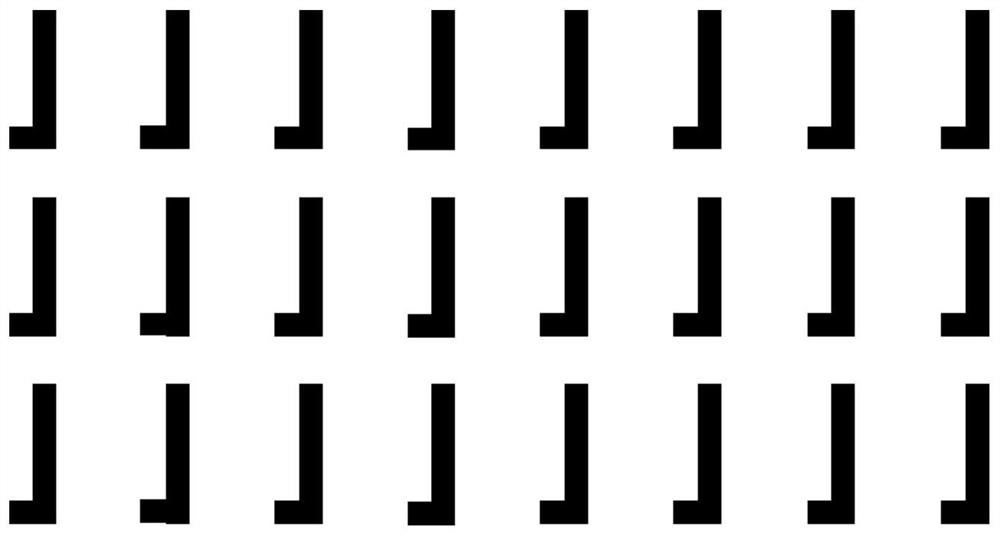

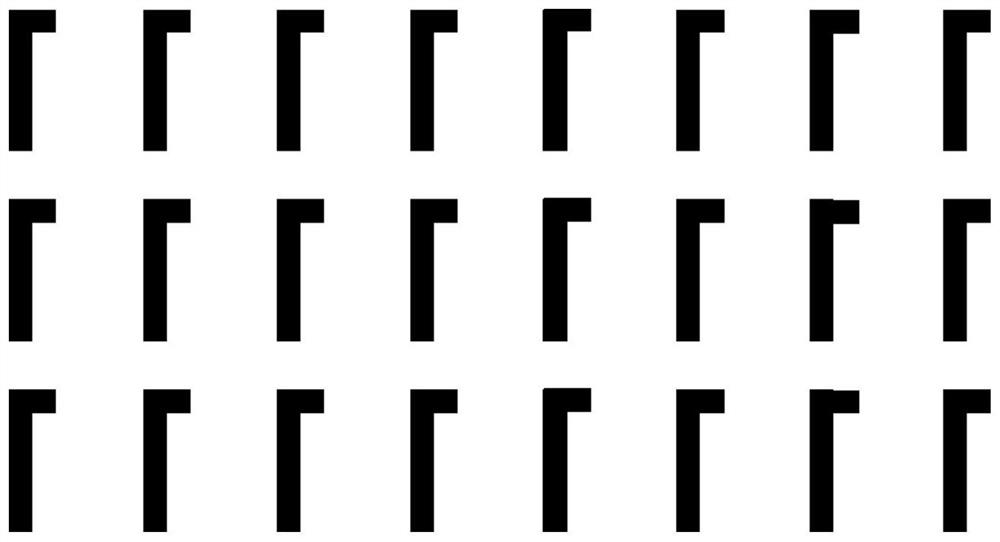

[0058] (3) Print the required N-type (or P-type) thermoelectric legs de...

Embodiment 2

[0068] Different from Example 1, the present invention selects a polyimide film with a thickness of 20 μm, on which electroless copper plating is used as the conductive base material, and DFP acrylate dry film negative photoresist is selected as the electroplating template to replace the SU8 negative ring Oxygen based liquid photoresists. Concrete preparation process is as follows:

[0069] (1) Configure an electroless copper plating solution, carry out electroless copper plating to the polyimide film, carry out ultrasonic cleaning to the copper-plated polyimide base material, degrease, and dry;

[0070] (2) The photoresist template can be heated and pressurized by using a wheeled laminator or other hot roller equipment. The pressure of the hot roller is 250Kpa, and the lamination speed is set to 20cm min -1 , the temperature of the equipment is set to 50°C, so that the dry film is melted and attached to the copper-plated polyimide side. Due to the flexibility of polyimide, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com