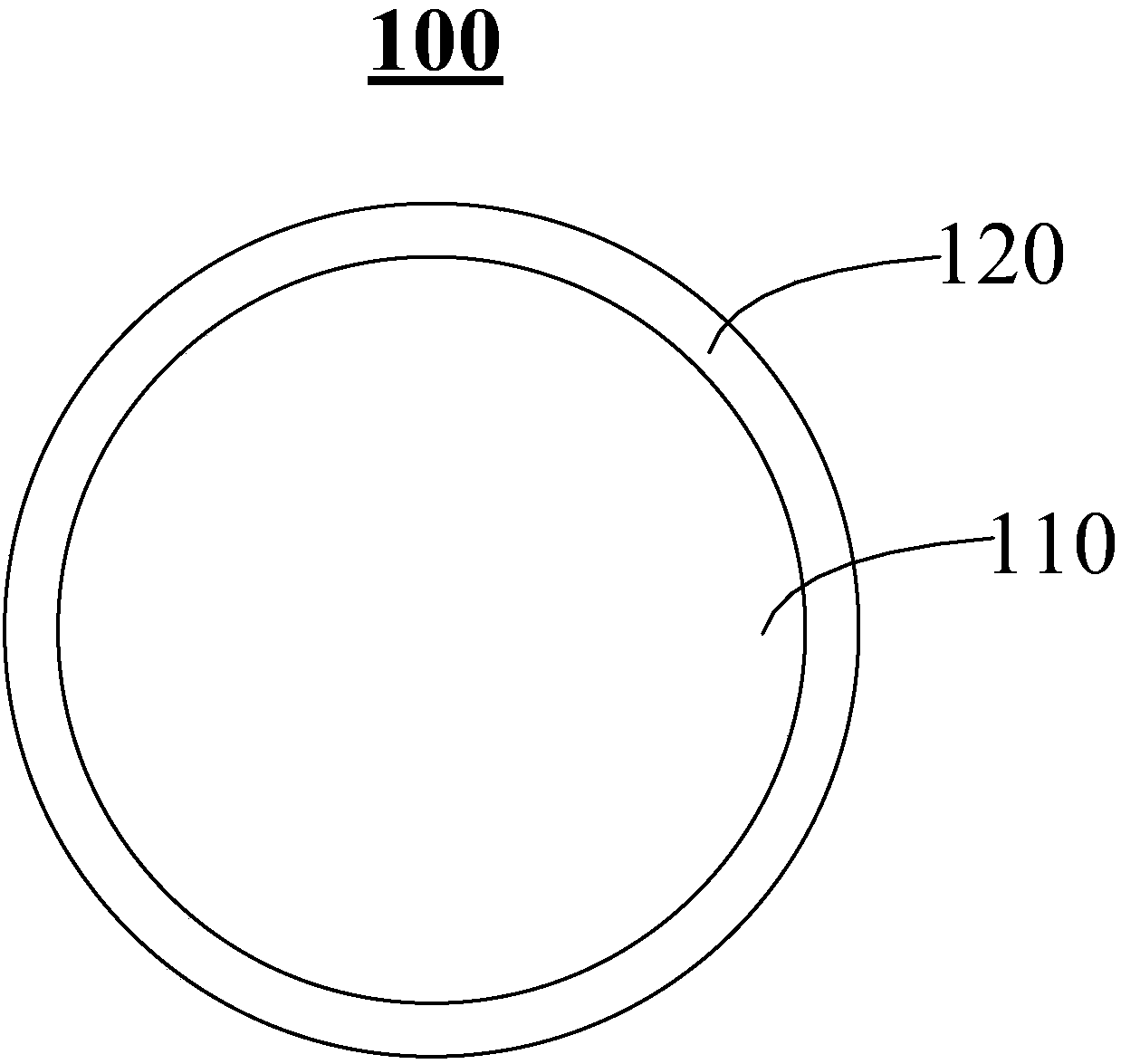

Lithium battery composite positive electrode material with core-shell structure and preparing method of lithium battery composite positive electrode material

A technology of composite positive electrode material and positive electrode material, applied in the field of lithium battery composite positive electrode material and its preparation, can solve the problems of reducing battery capacity, increasing battery internal resistance, etc., achieving a good transmission channel, reducing interface impedance, suitable for large-scale production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

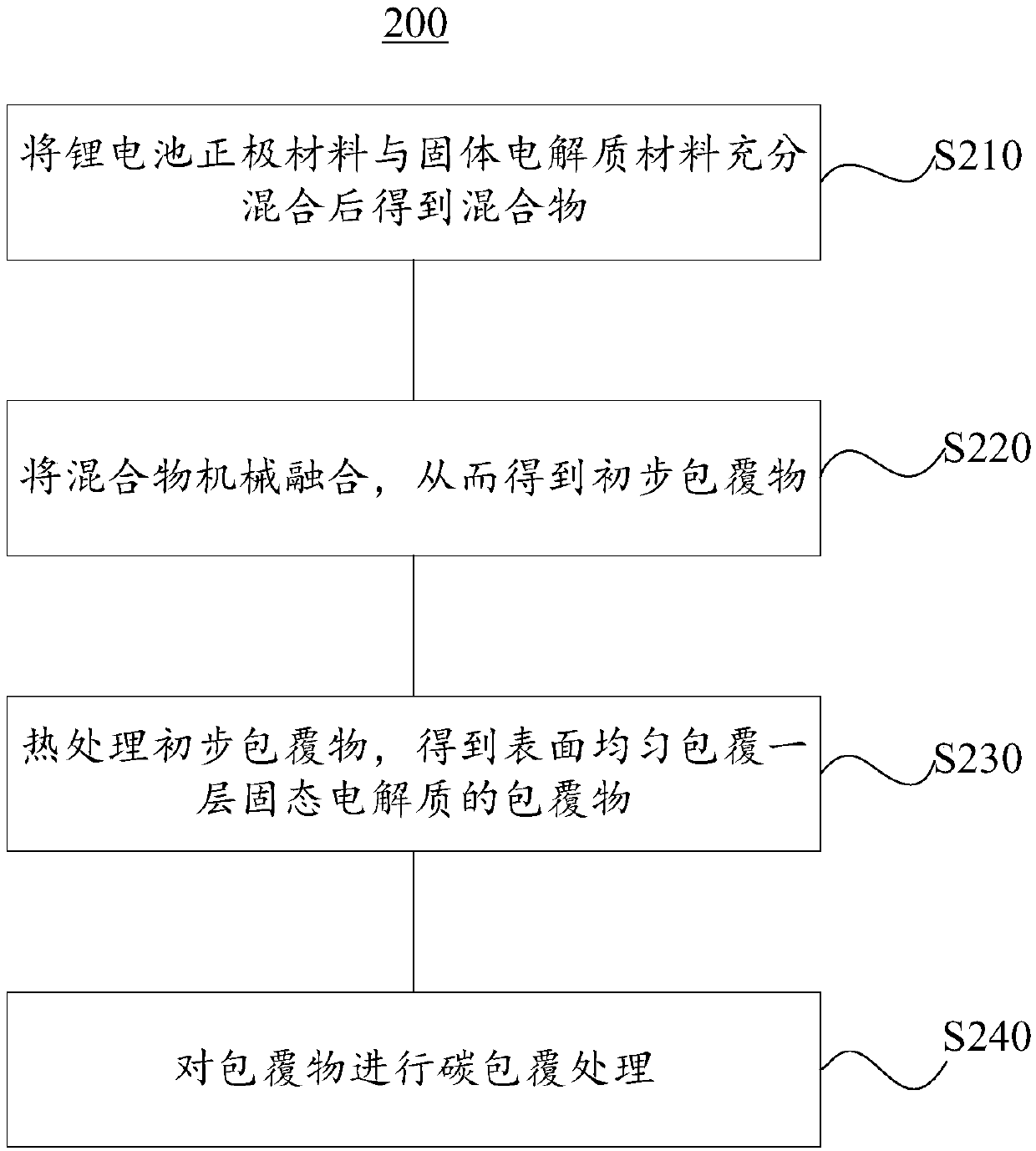

Method used

Image

Examples

example 1

[0044] 500g of lithium cobaltate (LCO) and 5g of Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3(LATP) was placed in a ball mill to fully mix the two, and the mixed material was placed in a fusion machine at a speed of 3000r / min. After fusion for 15mins, the LCO coated with LATP was taken out and placed in a tube furnace. In an air environment, the temperature was raised to 700 °C at a rate of 5 °C / min and kept for 4 h. Then put the obtained material and 1g of graphene back into the ball mill to fully mix the two, then take it out and put it in the fusion machine, and then fuse for 15mins, and finally you can get 1wt% LATP and 0.2wt% graphene coating Composite LCO cathode material with core-shell structure. SEM images of LCO powder before and after coating Figure 3A and 3B shown.

[0045] The coated LCO and the uncoated LCO materials were made into positive electrode sheets respectively, and a button-type liquid lithium-ion battery was made for performance comparison. The positive el...

example 2

[0047] 500g of lithium cobaltate (LCO) and 5g of Li 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 (LATP) was placed in a ball mill to fully mix the two, and the mixed material was placed in a fusion machine at a speed of 3000r / min. After fusion for 15mins, the LCO coated with LATP was taken out and placed in a tube furnace. In an air environment, the temperature was raised to 700 °C at a rate of 5 °C / min and kept for 4 h. Then put the obtained material and 1g of graphene back into the ball mill to fully mix the two, then take it out and put it in the fusion machine, and then fuse for 15mins, and finally you can get 1wt% LATP and 0.2wt% graphene coating Composite LCO cathode material with core-shell structure.

[0048] The coated LCO is used as the positive electrode active material to make a mixed solid-liquid metal lithium battery, which includes a positive electrode, a negative electrode, a solid electrolyte sheet between the positive electrode and the negative electrode, and a small amo...

example 3

[0050] 500g of lithium cobaltate (LCO) and 5g of Li 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 (LATP) was placed in a ball mill to fully mix the two, and the mixed material was placed in a fusion machine at a speed of 3000r / min. After fusion for 15mins, the LCO coated with LATP was taken out and placed in a tube furnace. In an air environment, the temperature was raised to 700 °C at a rate of 5 °C / min and kept for 4 h. Then put the obtained material and 1g of graphene back into the ball mill to fully mix the two, then take it out and put it in the fusion machine, and then fuse for 15mins, and finally you can get 1wt% LATP and 0.2wt% graphene coating Composite LCO cathode material with core-shell structure.

[0051] The coated LCO is used as a positive electrode active material to make an all-solid metal lithium battery, which includes a positive electrode, a negative electrode, and a solid electrolyte sheet between the positive electrode and the negative electrode. The mass ratio of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com