Low-density oil-well cement

An oil well cement, low-density technology, applied in the field of building materials, can solve the problems of occupying land and polluting the environment, and achieve the effects of low density, good fluidity, and stable high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

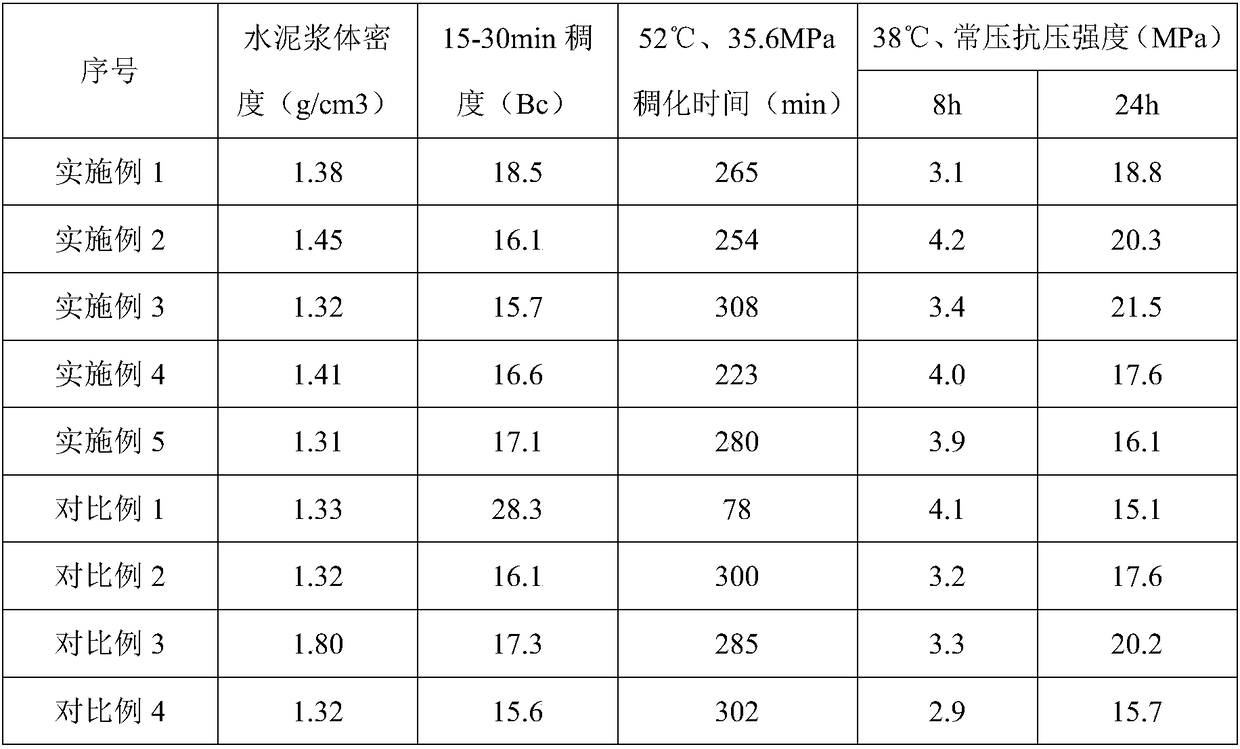

Examples

Embodiment 1

[0020] A low-density oil well cement composed of the following parts by weight: 40 parts G-grade oil well cement, 5 parts phosphogypsum, 10 parts waste glass powder, 40 parts fly ash, 0.5 parts plastic expansion agent, 1 part stabilizer Parts, 0.5 parts of retarder, 0.03 parts of enhancer, 1 part of dispersant, 2 parts of aluminum dihydrogen phosphate.

[0021] The waste glass powder is crushed and ground from waste glass to a specific surface area ≥ 400m 2 / kg obtained.

[0022] The plastic expansion agent is calcium peroxide.

[0023] The stabilizer is composed of magnesium aluminum silicate and propylene glycol alginate.

[0024] The retarder is composed of polyol phosphate and sucrose.

[0025] The enhancer is composed of triethanolamine and sodium nitrophenolate in a weight ratio of 2:1.

[0026] The dispersant is composed of polycarboxylic acid water reducing agent and dioctyl succinate sulfonic acid in a weight ratio of 8:1.

Embodiment 2

[0028] A low-density oil well cement composed of the following parts by weight: 60 parts G-grade oil well cement, 2 parts phosphogypsum, 20 parts waste glass powder, 30 parts fly ash, 3 parts plastic expansion agent, 0.05 parts stabilizer Parts, 1 part retarder, 0.01 parts enhancer, 3 parts dispersant, 0.5 parts aluminum dihydrogen phosphate.

[0029] The waste glass powder is made of SiO 2 Waste glass with a content of ≥60% is crushed and ground to a specific surface area of ≥400 m 2 / kg obtained.

[0030] The bulk density of the fly ash≤750kg / m 3 .

[0031] The plastic expansion agent is ammonium chloride.

[0032] The stabilizer is composed of magnesium aluminum silicate and propylene glycol alginate in a weight ratio of 3:1.

[0033] The retarder is composed of polyol phosphate and sucrose in a weight ratio of 1:1.

[0034] The enhancer is composed of triethanolamine and sodium nitrophenolate in a weight ratio of 5:1.

[0035] The dispersant is composed of polycarboxylic acid water...

Embodiment 3

[0037] A low-density oil well cement composed of the following parts by weight: 50 parts G grade oil well cement, 4 parts phosphogypsum, 15 parts waste glass powder, 35 parts fly ash, 2 parts plastic expansion agent, 0.5 parts stabilizer Parts, 0.8 parts of retarder, 0.02 parts of enhancer, 2 parts of dispersant, 1.2 parts of aluminum dihydrogen phosphate.

[0038] SiO in the waste glass powder 2 The content is ≥60%.

[0039] The plastic expansion agent is azodicarbonamide.

[0040] The stabilizer is composed of magnesium aluminum silicate and propylene glycol alginate.

[0041] The retarder consists of total phosphorus (in PO 4 3- Count) Polyol phosphate and sucrose with content ≥30%.

[0042] The enhancer is composed of triethanolamine and sodium nitrophenolate in a weight ratio of 3:1.

[0043] The dispersant is composed of polycarboxylic acid water reducing agent and dioctyl succinate sulfonic acid in a weight ratio of 6:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com