Sulfamic acid carboxylic ester terminated polyether, and preparation method and application thereof

A technology of sulfamic acid carboxylate and end-capped polyether, which is applied in the field of organic chemistry, can solve problems such as unsatisfactory stacking effects, and achieve the effects of simple and easy-to-obtain production materials, anti-corrosion, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a sulfamic acid carboxylate-terminated polyether and a preparation method thereof, the method being specifically:

[0034] Arginine, p-toluenesulfonic acid, and methallyl polyoxyethylene ether with a molar ratio of 1.25:2.5:1 are used as raw materials, and the raw materials are esterified at 120°C for 3 hours to obtain sulfamic acid carboxyl Ester-terminated polyether (HPEG-AT).

Embodiment 2

[0036] This embodiment provides the preparation of anti-rust polycarboxylate water reducer ZX-PCE-1, specifically as follows:

[0037] Take 1100 parts (parts by mass) of HPEG-AT prepared in Example 1, add 780 parts by mass of water to it, raise the temperature, and dropwise add ammonium persulfate containing Mixed liquid with acrylic acid (6.5 parts of ammonium persulfate, 80 parts of acrylic acid), aqueous solution of mercaptopropionic acid (3.0 parts of mercaptopropionic acid, 160 parts of water), control the dropping speed, and drop them in 150±10 minutes and 180±10 minutes respectively , keep the temperature at 45±2°C, continue the reaction for 1 hour, cool down to 35°C, add an aqueous solution containing tetraethylenepentamine and arginine (2.5 parts of tetraethylenepentamine, 3.5 parts of arginine, 45 parts of water), Obtained 50% anti-rust polycarboxylate superplasticizer ZX-PCE-1.

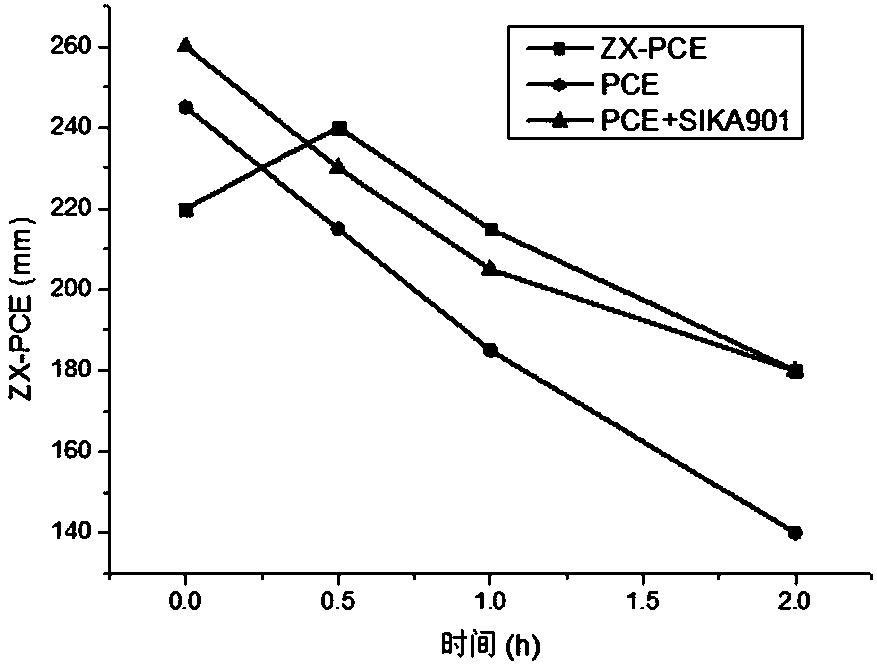

[0038] After testing, the water reducer prepared in this example has a pH of 7.8 and a...

Embodiment 3

[0041] This embodiment provides the preparation of anti-rust polycarboxylate water reducer ZX-PCE-2, specifically as follows:

[0042] Take 1100 parts (parts by mass) of HPEG-AT prepared in Example 1, add 780 parts by mass of water, heat up, and add ammonium persulfate and acrylic acid dropwise at a temperature of 45°C±2°C. Mixed solution (6.5 parts of ammonium persulfate, 80 parts of acrylic acid) and aqueous solution of mercaptopropionic acid (3.0 parts of mercaptopropionic acid, 160 parts of water), control the dropping speed, and finish dropping at 150±10 minutes and 180±10 minutes respectively, keep the temperature At 45±2°C, continue to react for 1 hour, cool down to 35°C, add an aqueous solution containing triethylenetetramine and arginine (3.0 parts of triethylenetetramine, 3.5 parts of arginine, 45 parts of water) to obtain the present invention 50% antirust polycarboxylate superplasticizer ZX-PCE-1.

[0043] After testing, the pH was 7.5 and the concentration was 51...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com