Preparation method of low-viscosity caramel pigment and production device thereof

A caramel color, production equipment technology, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc. It can reduce the problems such as lowering of the property, and achieve the effect of wide application, lower content and lower viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

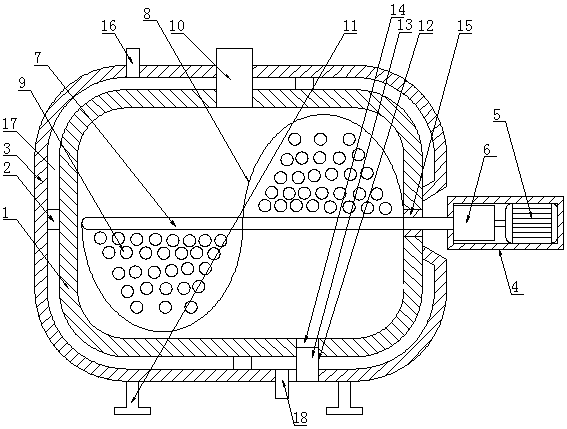

[0025] A production equipment for caramel color preparation, including kettle body 1, connecting column 2, jacket 3, casing 4, stirring motor 5, reducer 6, stirring shaft 7, spiral stirring plate 8, through hole 9, feeding Port 10, foot 11, discharge valve 12, movable layer 13, fixed layer 14, shaft seal 15, steam outlet 16, interlayer 17, steam outlet 18; among them, a stirring motor 5 is installed inside the shell 4, and the output of the stirring motor 5 is A reducer 6 is installed at the output end of the reducer 6, and a stirring shaft 7 is installed at the output end of the reducer 6. The stirring shaft 7 passes through the shaft seal 15 and is fixedly connected with the spiral stirring piece 8. The spiral stirring piece 8 is placed inside the kettle body 1, and the spiral stirring piece 8 is A through hole 9 is provided, the upper part of the still body 1 is provided with a feed inlet 10, and the lower part is provided with a discharge valve 12, the discharge valve 12 is...

Embodiment 2

[0030] A method for preparing low-viscosity caramel pigment: 1) Take 1000g of fresh corn kernels and grain mixture with a mass ratio of 1:1 and 30ml of food-grade hydrochloric acid into a ball mill, and grind at a speed of 350r / min and 1:1 After ball milling for 10 minutes at the ball material ratio, transfer the ball mill material in the ball mill tank to the mixer, add 1 times the amount of water of the ball mill material and 3% of the total amount of amylase, heat up to 70 degrees Celsius and react for 30 minutes, then cool After reaching room temperature, press filter and collect the filtrate; 2) Transfer the filtrate to the production equipment described in Example 1, and add 0.3 ammonium sulfite with the quality of the filtrate, and raise the temperature at a rate of 3°C / min to After 135 degrees Celsius, react for 1.5h, then add 0.1% sucrose lipid based on the mass of the filtrate, and continue to react for 2h under a pressure of 2MPa. After cooling, discharging, and conc...

Embodiment 3

[0032]A preparation method of low-viscosity caramel coloring: 1) Take 1000g of fresh mixture of grain and chestnut with a mass ratio of 1:1 and 30ml of food-grade hydrochloric acid and add it to a ball mill pulverizer. After milling for 15 minutes at a lower ball-to-material ratio, transfer the milled material in the ball mill tank to the mixer, add 1 times the amount of water and 3% of the total amount of amylase to the milled material, heat up to 80 degrees Celsius and react for 15 minutes, then cool to After room temperature, press filter to collect the filtrate; 2) transfer the filtrate to the production equipment described in Example 1, and add 0.8% ammonium sulfite of the filtrate quality, and heat up to After 100 degrees Celsius, react for 2 hours, then add 0.05% sucrose lipid according to the mass of the filtrate, and continue to react for 4 hours under a pressure of 1.5 MPa. After cooling, discharging, and concentrating, the existing caramel pigment is obtained. Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com