Preparation method and application of metal-polyphenol nano-particles

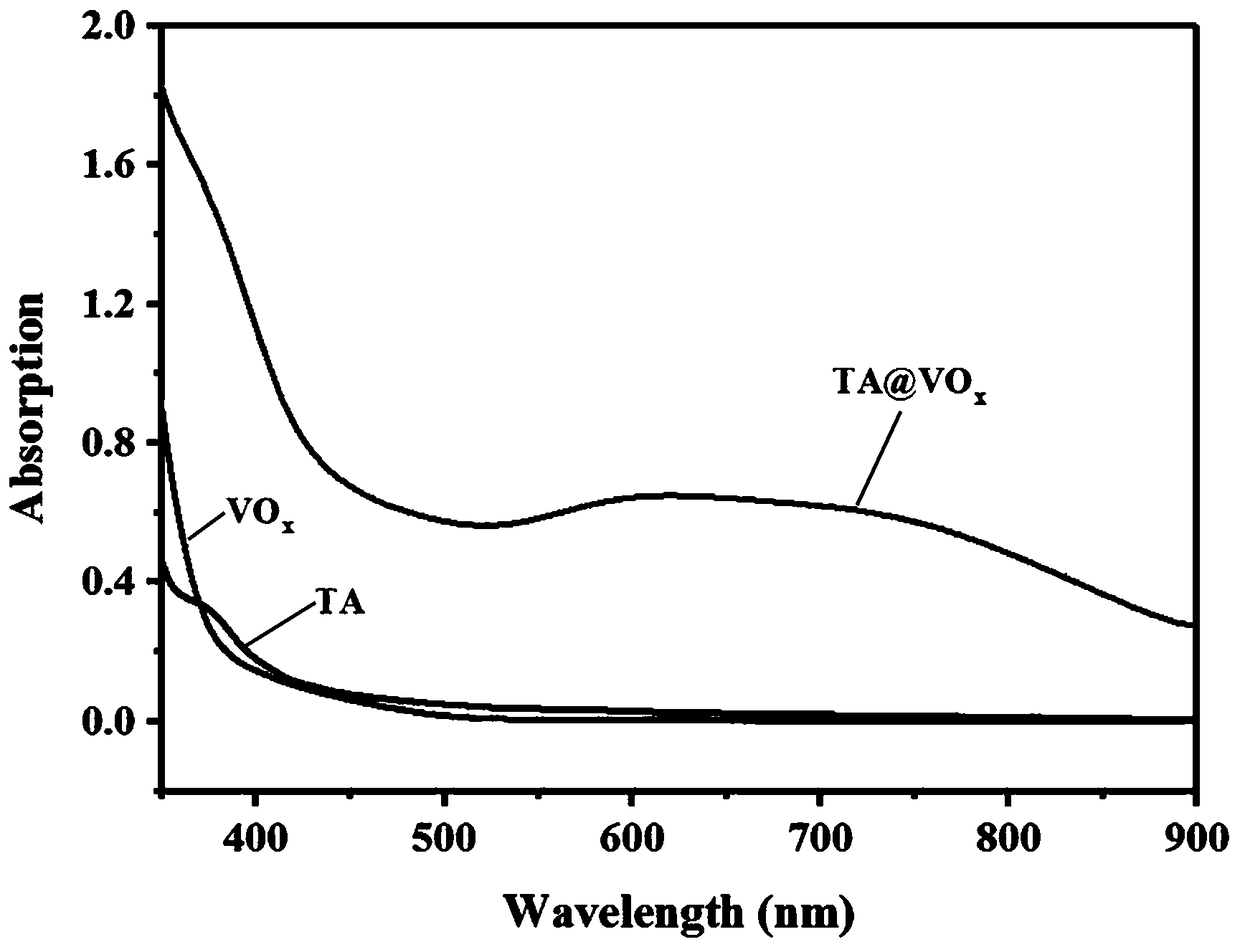

A nanoparticle and metal technology, applied in the field of nanoparticle preparation, can solve the problems of reduced photothermal treatment effect, weakened EPR effect, shortened cycle time, etc., and achieves the effects of good biodegradability, good absorption, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of metal-polyphenol nanoparticles, comprising the steps of:

[0022] 1) Weigh 2.5 g of tannic acid and dissolve in 70 mL of distilled water, and dissolve 0.1 g of ammonium metavanadate in 30 mL of distilled water, and stir them evenly for later use;

[0023] 2) Heat the ammonium metavanadate solution to 60°C and stir for 60 min to obtain a golden yellow solution, namely the vanadium oxide solution;

[0024] 3) After adding the vanadium oxide solution dropwise to the tannic acid solution, react at 60°C for 24 h to obtain a black solution;

[0025] 4) Dialyze the black solution obtained in the previous step, change the distilled water every 2-3 hours for the first 12 hours, and change the distilled water every 5-6 hours for the next 36 hours to obtain the final product.

[0026] 5) The storage temperature of the final product is 4°C.

Embodiment 2

[0028] A preparation method of metal-polyphenol nanoparticles, comprising the steps of:

[0029] 1) Weigh 2.5 g of tannic acid and dissolve in 70 mL of distilled water, and dissolve 0.1 g of ammonium metavanadate in 30 mL of distilled water, and stir them evenly for later use;

[0030] 2) Heat the ammonium metavanadate solution to 80°C and stir for 30 minutes to obtain a golden yellow solution, namely the vanadium oxide solution;

[0031] 3) After adding the vanadium oxide solution dropwise to the tannic acid solution, react at 80°C for 24 h to obtain a black solution;

[0032] 4) Dialyze the black solution obtained in the previous step, change the distilled water every 2-3 hours for the first 12 hours, and change the distilled water every 5-6 hours for the next 36 hours to obtain the final product.

[0033] 5) The storage temperature of the final product is 4°C.

Embodiment 3

[0035] A preparation method of metal-polyphenol nanoparticles, comprising the steps of:

[0036] 1) Weigh 2.5 g of tannic acid and dissolve in 70 mL of distilled water, and dissolve 0.1 g of ammonium metavanadate in 30 mL of distilled water, and stir them evenly for later use;

[0037] 2) Heat the ammonium metavanadate solution to 100°C and stir for 10 minutes to obtain a golden yellow solution, namely the vanadium oxide solution;

[0038] 3) After adding the vanadium oxide solution to the tannic acid solution dropwise, react at 100°C for 24 h to obtain a black solution;

[0039] 4) Dialyze the black solution obtained in the previous step, change the distilled water every 2-3 hours for the first 12 hours, and change the distilled water every 5-6 hours for the next 36 hours to obtain the final product.

[0040] 5) The storage temperature of the final product is 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com