Antibacterial non-stick material, preparation method thereof and antibacterial non-stick pan

A technology of antibacterial materials and non-stick coatings, which can be applied to special materials for cooking utensils, kitchen utensils, household appliances, etc. It can solve the problems of lack of antibacterial properties, poor use effect, and single function of non-stick coatings to achieve strong adhesion , Prevent bacterial growth, and the effect of simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

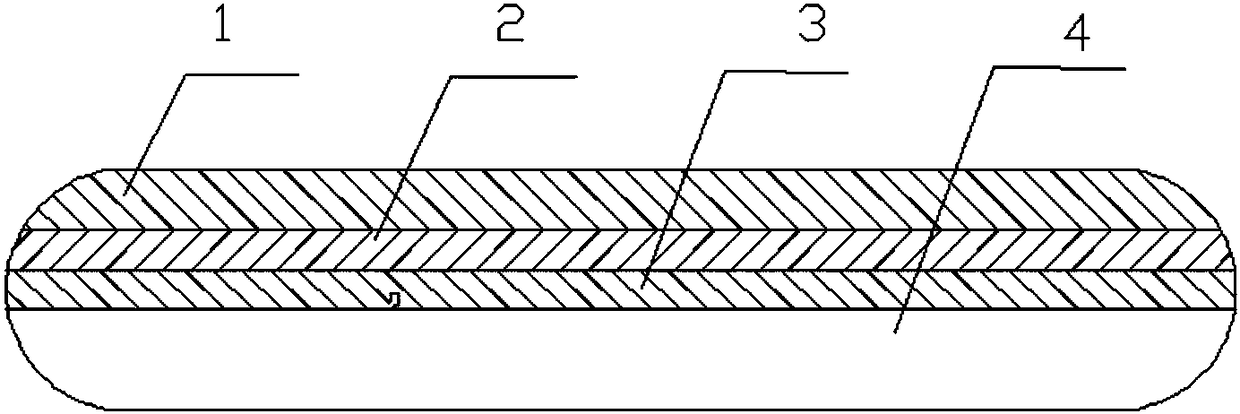

[0018] The first object of the present invention provides a kind of preparation method of antibacterial non-stick material, this method comprises: (1) aluminum oxide powder is formed aluminum oxide layer on the surface of base material by thermal spraying; (2) non-stick coating a forms a primer layer on the aluminum oxide layer by first spraying; (3) forms an antibacterial surface layer on the bottom layer by spraying an antibacterial coating to obtain an antibacterial non-stick material; wherein, the antibacterial coating is Composition containing antibacterial material and non-stick coating b, described antibacterial material is selected from the antibacterial agent containing at least one in silver, zinc, copper and zinc oxide; Based on the weight of described antibacterial coating, described antibacterial coating The content of the antibacterial material in terms of Ag, Zn or Cu is 0.8-10% by weight; the base material is a metal base material, a ceramic base material or a c...

Embodiment 1

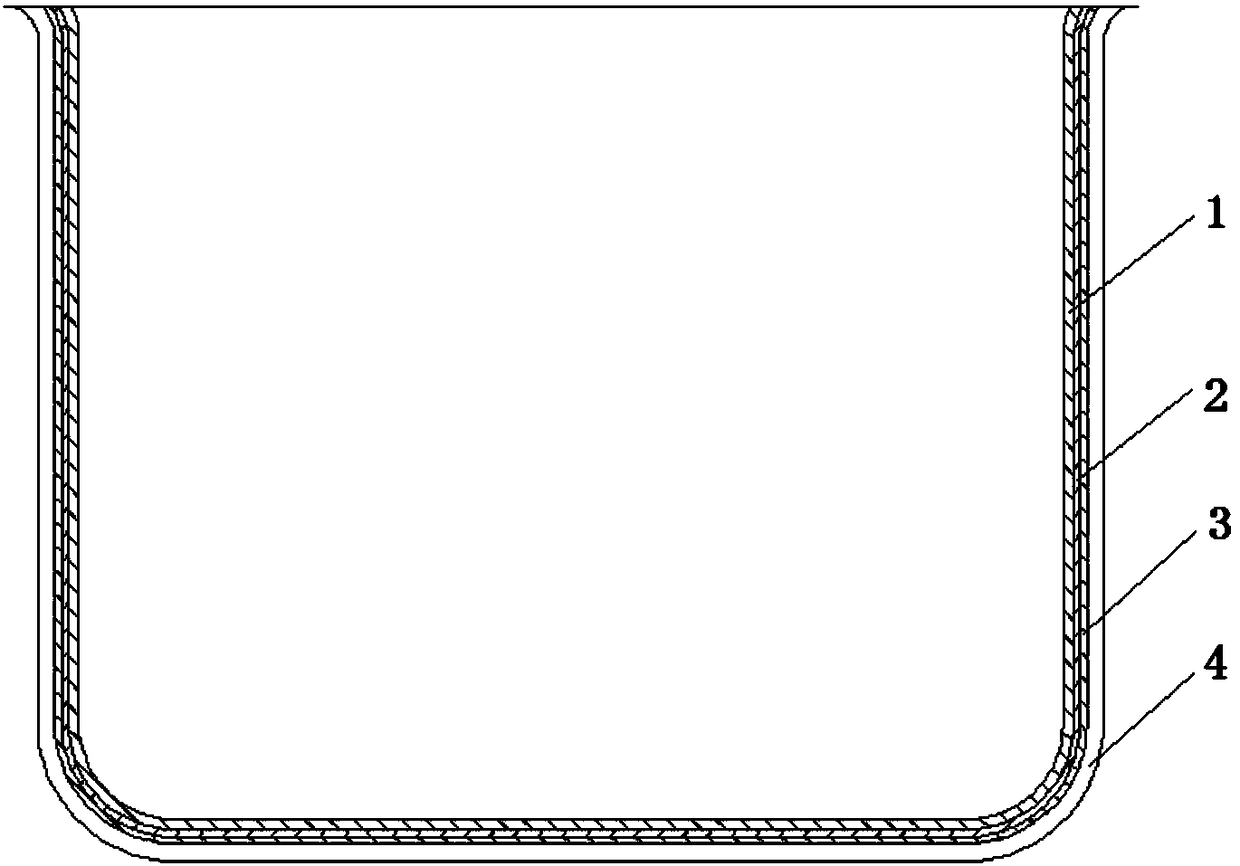

[0063] (1) Press and form an aluminum base material with a thickness of 0.8mm into the inner pot of the electric rice cooker, then degrease the inner surface of the inner pot of the electric rice cooker, and spray the inner surface of the cleaned inner pot with 60# alumina sand Sand treatment, the compressed air pressure is 0.8MPa during sandblasting, the sandblasting distance is 50mm, and the surface roughness Ra of the inner surface reaches 3μm;

[0064] (2) On the inner surface of the inner pot after step (1), aluminum oxide powder is thermally sprayed to form an aluminum oxide layer. The thermal spraying process conditions are: spraying distance 120mm, spraying power 20kW, main gas is Ar (flow rate 30L / min), the auxiliary gas is hydrogen (flow rate 6L / min), the spray gun moving speed is 400mm / s, the spraying angle is 85°; the thickness of the aluminum oxide layer is 20μm;

[0065] (3) Preheat the inner pot obtained in step (2) to 40°C; then, on the aluminum oxide layer, s...

Embodiment 2

[0073] (1) Process the aluminum substrate with a thickness of 3mm into a wok, then degrease the inner surface of the wok, and then use 80# alumina sand to sandblast the inner surface of the cleaned wok, When sandblasting, the compressed air pressure is 0.7MPa, the sandblasting distance is 100mm, and the surface roughness Ra of the inner surface reaches 3.5μm;

[0074] (2) On the inner surface of the frying pan after step (1), aluminum oxide powder is thermally sprayed to form an aluminum oxide layer. The thermal spraying process conditions are: spraying distance 120mm, spraying power 10kW, main gas is Ar (flow rate 30L / min), the auxiliary gas is hydrogen (flow rate 6L / min), the moving speed of the spray gun is 400mm / s, and the spraying angle is 80°; the thickness of the aluminum oxide layer is 35μm;

[0075] (3) Preheat the frying pan obtained in step (2) to 35°C; then, on the aluminum oxide layer, carry out the first spraying of the water-based fluororesin coating T3, using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com