Method for preparing cobalt oxalate by ammonia-free oxalic acid precipitation

A technology of cobalt oxalate and aminooxalic acid, applied in carboxylate preparation, carboxylate preparation, organic chemical methods, etc., can solve environmental hazards, environmental protection violations, high investment and operation costs, etc., to save production costs and reduce environmental hazards effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention and its effects will be further described below through the research of thermodynamic behavior analysis, dynamic behavior analysis and experimental process of the present invention.

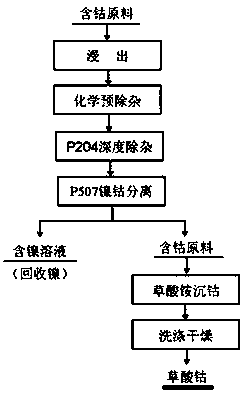

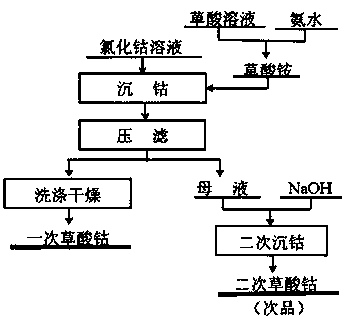

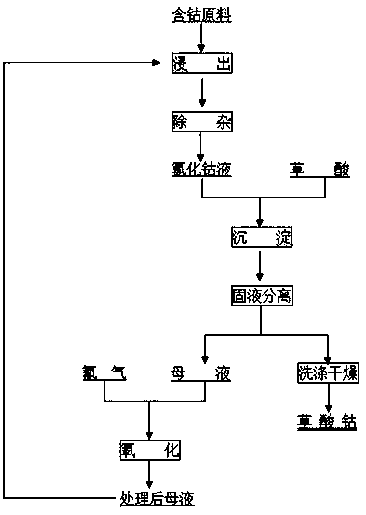

[0040]A method for preparing cobalt oxalate by ammonia-free oxalic acid precipitation, using cobalt-containing waste residue (the waste residue mainly comes from the smelting process of copper-nickel sulfide ore, containing 0.2-07% cobalt), and acid leaching by sulfuric acid, hydrochloric acid or a mixed acid of hydrochloric acid and sulfuric acid treatment, leaching the cobalt in the waste residue to obtain a cobalt-containing solution, and then obtain a relatively pure cobalt chloride solution after oxidation hydrolysis, sulfide precipitation primary impurity removal and P204 ion extraction deep impurity removal, and then oxalic acid solution As a precipitating agent, the precipitation reaction is carried out under agitation, and finally the cobalt oxalate crystal wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com