Anti-counterfeiting ink with delayed fluorescence and application of ink

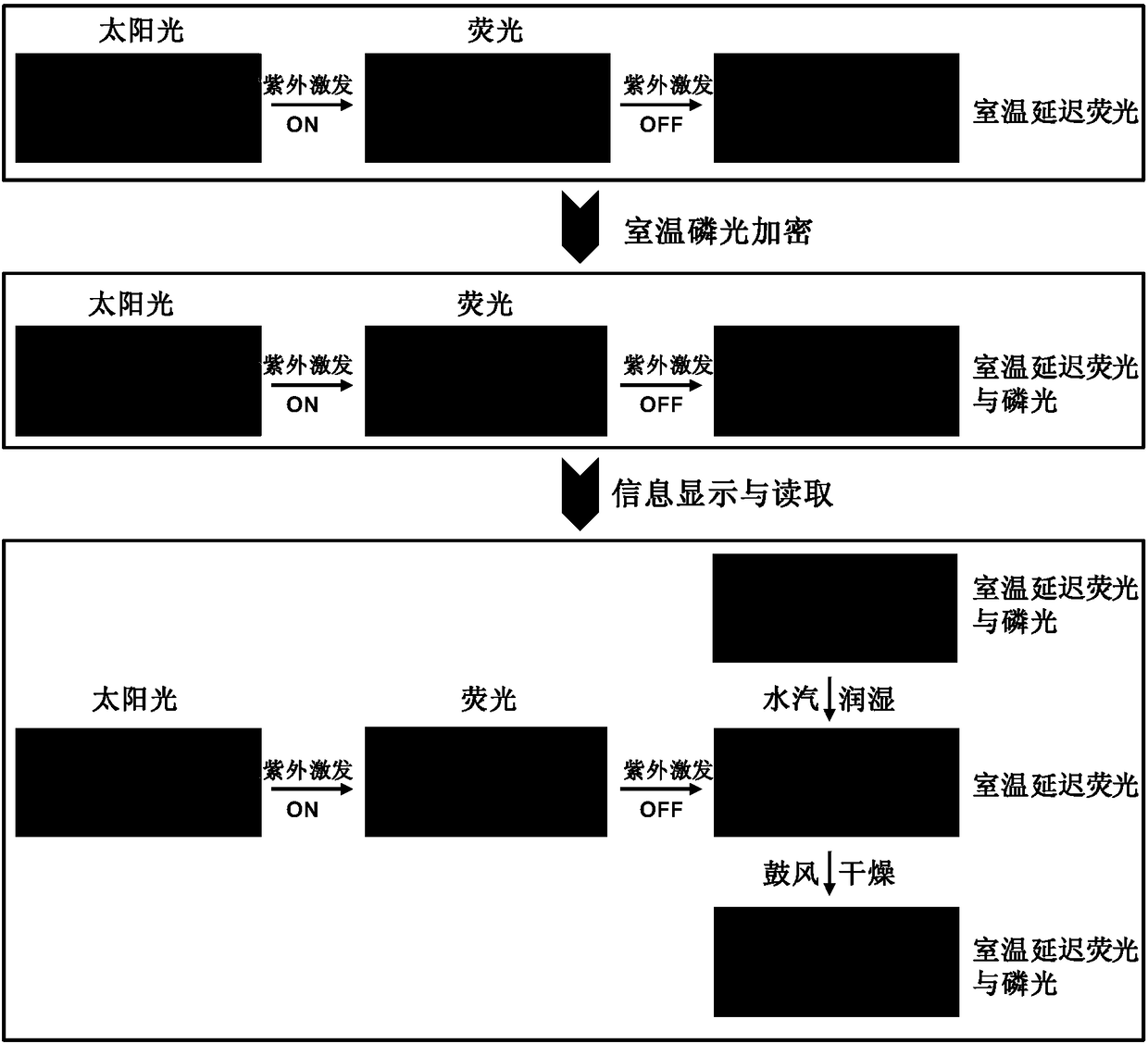

A delayed fluorescence, anti-counterfeiting ink technology, applied in the fields of chemistry and material science, can solve the problem that the anti-counterfeiting performance of anti-counterfeiting labels needs to be improved, and achieve the effect of fast and convenient information hiding and reading, convenient operation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In some preferred embodiments, the preparation method of the delayed fluorescent material comprises:

[0034] mixing the first fluorescent material and the silicon dioxide material in a solvent to form a mixed reaction solution,

[0035] The mixed reaction solution is heated to 100-200° C. and reacted for 3-18 hours under the condition of a pressure of 2-4 MPa, and then post-treated to obtain the delayed fluorescent material.

[0036] Further, the first fluorescent material adopts the fluorescent material provided by CN103525402A.

[0037] Preferably, the mass ratio of the first fluorescent material to the silicon dioxide material is 0.5-2.5:25-1250.

[0038] In some embodiments, the preparation method of the delayed fluorescent material comprises:

[0039] dispersing the first fluorescent material in a solvent to form a first fluorescent material dispersion,

[0040] Dispersing the silica material in a solvent to form a silica material dispersion,

[0041] The firs...

Embodiment 1

[0086] Example 1 This example provides an anti-counterfeiting ink with delayed fluorescence, which includes the following raw materials (parts by weight): 100 parts of ethanol, 50 parts of polyvinyl alcohol, 1300 parts of water, and 50 parts of room temperature long-life delayed fluorescent material.

[0087] The preparation method of this delayed fluorescent anti-counterfeiting ink is as follows:

[0088] Disperse 50 parts of room temperature long-life delayed fluorescent material in 100 parts of ethanol, add 300 parts of water to dilute to obtain solution A;

[0089] Dissolve 50 parts of polyvinyl alcohol in 1000 parts of water to obtain solution B;

[0090] After mixing the solutions A and B, put them into a vacuum drying oven and vacuumize at room temperature until the air bubbles in the mixed solution are removed to obtain the anti-counterfeiting ink with delayed fluorescence.

[0091] The preparation method of the aforementioned long-life delayed fluorescent material at...

Embodiment 2

[0106]Example 2 A phosphorescent anti-counterfeiting ink provided in this example contains the following raw materials (parts by weight): 180 parts of ethanol, 23 parts of polyvinyl alcohol, 1100 parts of water, and 1.0 part of the blue fluorescent material disclosed in CN103525402A.

[0107] The preparation method of the anti-counterfeiting ink with phosphorescence is as follows:

[0108] After dispersing 1.0 parts of blue fluorescent material in 180 parts of ethanol, adding 150 parts of water to dilute to obtain a blue fluorescent material dispersion;

[0109] Dissolve 23 parts of polyvinyl alcohol in 950 parts of water to obtain a polyvinyl alcohol solution;

[0110] After mixing the blue light fluorescent material dispersion liquid and the polyvinyl alcohol solution, put it into a vacuum drying oven, and vacuumize at room temperature until the air bubbles in the mixed liquid are removed, so as to obtain the anti-counterfeiting ink with phosphorescence.

[0111] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com