A start-up method of ebullating bed-fixed bed combined process

A combined process and fixed bed technology, which is applied in the fields of hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of increased pressure drop and difficult discharge, etc., so as to reduce the pressure drop of the device, reduce the start-up time, and stabilize the The effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

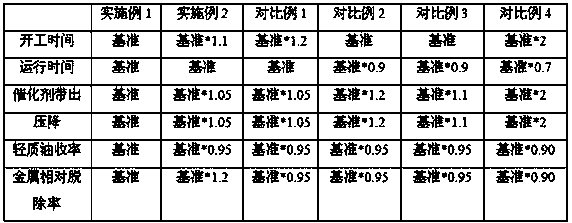

Embodiment 1

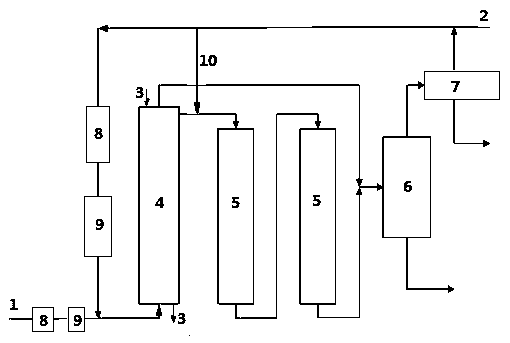

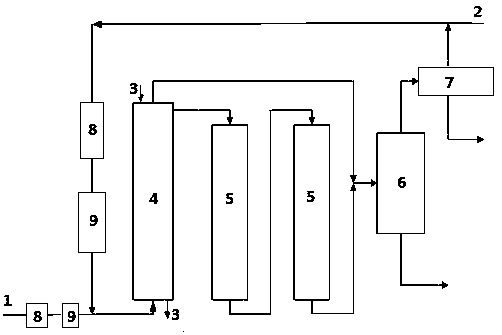

[0036] The specific operation process is as follows: the catalyst 3 is loaded into the ebullated bed reactor 4 and the fixed bed reactor 5 from the top, and the pressurization line 10 between the ebullated bed 4 and the fixed bed 5 is boosted at a speed of 1.5-2.5 MPa / h, after rising to the pressure required for the reaction, the starting diesel oil enters the part of the pipeline between the ebullating bed 4 and the fixed bed 5 from the raw material pump, heat exchanger 8, heating furnace 9, etc., and enters the ebullating bed reactor respectively 4 and fixed bed 5 to achieve oil feed and catalyst wetting. After the nuclear density meter shows that the ebullated bed reactor reactor 4 realizes catalyst wetting, switch to the conventional raw material pump, heat exchanger 8, heating furnace 9, and ebullated bed Reactor 4, fixed bed reactor 5, separator 6 and the fractionation part, according to the heating rate of 10-20 ℃ / h, further complete the process of vulcanization, raw m...

Embodiment 2

[0038] Same as Example 1, except that the ebullated bed catalyst used is prepared as follows: Weigh 200g of pseudoboehmite dry rubber powder (produced by Wenzhou Jingjing Alumina Co., Ltd.) and place it in a round bottom flask, add 600 g of gram of deionized water for beating, add an appropriate amount of nitric acid molar concentration to the above slurry with a molar concentration of 3mol / L, and a mixed acid solution with a molar concentration of acetic acid of 1mol / L, control the pH value of the slurry to 3 and heat to reflux at 40°C for 3 hours. The above slurry was transferred into an autoclave, 20 g of urea was added to the mixed material, and the autoclave was sealed and heat treated at 140° C. for 6 hours. After cooling to room temperature, the mixed slurry was filtered, washed, and dried at 120° C. for 8 hours to obtain pseudo-boehmite.

[0039] Weigh 200 g of the above-mentioned pseudo-boehmite and place it in a beaker, add 400 mL of xylitol aqueous solution with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com